365nm UV Inspection Light: Vital Tool for Quality & Safety

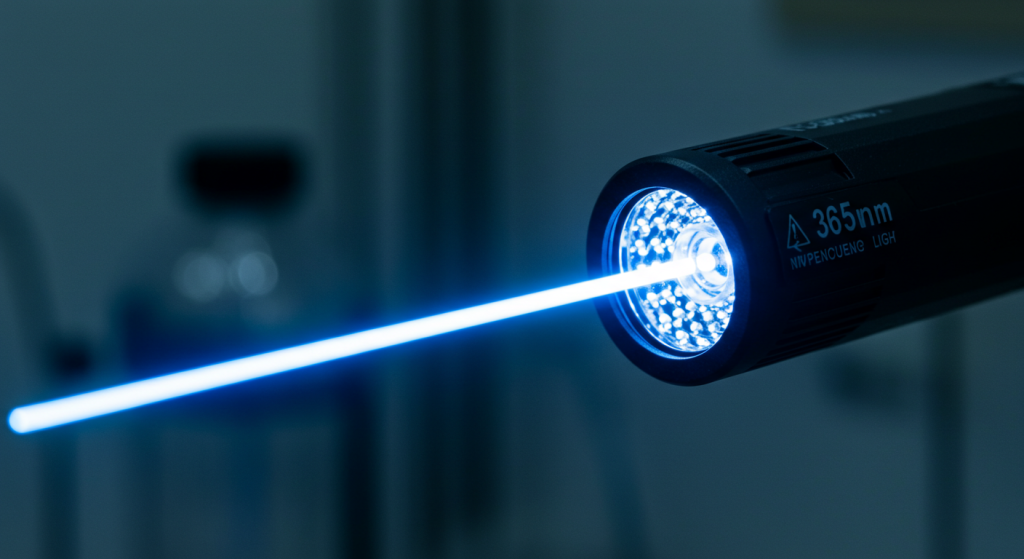

What is a 365nm UV Inspection Light?

A 365nm UV inspection light falls under the UV-A category because it produces ultraviolet radiation at a wavelength of 365 nanometers. The 365nm wavelength is often preferred over other ranges, such as 395nm, because it is “true UV light,” which lacks visible violet light. For the detection of fluorescent materials such as certain dyes used in penetrant tests and leak detection, pure UV emission is critical. The light triggers the dyes and particles, causing them to glow when exposed to UV light. Because of this, fractures, leaks, contaminants, or even forged documents are easy to identify.

The Ultimate Guide to the 365nm UV Inspection Light: Its Precision, Power, and Performance

Every modern industry today requires effective inspection and quality control as a routine process. 365nm UV Inspection light is gaining acceptance across industries such as non-destructive testing (NDT), automotive diagnostics, forensic analysis, and even HVAC systems for leak detection. This article discusses the significance of the 365nm wavelength as well as its applications and operational principles of UV-A light.

What Makes 365nm UV Lights Better Than 395nm UV Lights?

Most applications utilize 395nm UV lights, primarily because they are more economical due to the visible violet glow they emit. This glow can be counterproductive when reading fluorescence. 365nm UV lights offer optimal performance for the following reasons:

• True UV-A Emission: Achieves maximum fluorescence response while preventing interference by visible light.

• Higher Contrast: Better visualization of finer details in fluorescent dyes, which is advantageous in leak detection or penetrant inspection.

• Improved Sensitivity: Greater ability to detect small cracks, stains, or contaminants that other UV lights would miss.

• Professional Standard: Accepted in NDT, forensic examinations, and industrial inspections.

How Does a 365nm UV Inspection Light Work?

The operating principle behind 365nm UV LED inspection lights utilizes specially constructed bulbs within the UV-A range. Let's break it down simply:

1. UV LED Source: Every lamp has high-powered LEDs that can emit and maintain a specific narrow wavelength of 365nm.

2. Excitation of Fluorescent Dye: The UV light excites and activates the electrons present in fluorescent dyes or particles, which are commonly used.

3. Fluorescence Emission: The excited particles will emit light in a fluorescent form, which is light as a result of energy absorption.

4. Detection: Inspectors can accurately detect the presence of leaks, cracks, stains, or even counterfeited security features by utilizing this glow.

UV100-N: Premium 365nm UV LED Inspection Light for NDT

The flashlight UV100-N is a 365nm UV LED flashlight for non-destructive tests (NDT) such as Fluorescent Penetrant Inspection (FPI) and Magnetic Particle Inspection (MPI). The flashlight is portable and features high power, international compliance, and is suitable for industrial inspections.

- Powerful Nichia 365nm UV LED

The most powerful feature of the UV100-N is the niche 365nm UV LED the flashlight is equipped with. For time-pressed inspections, the instant-on LED is a game changer because it does not require warm-up time. Its dependability adds to its over 20,000-hour reliability claim.

- High Coverage and UV Intensity

This inspection light has a 100mm coverage area with a UV-A intensity of 15,000 μW/cm². The UV100-N is instrumental in enhancing precision for metal crack detection, aerospace inspections, and welding flaw identification by illuminating micro and hairline cracks.

- ASTM and MIL Standards Compliance

Due to its specially designed filter glass, the UV100-N ascertains compliance with ASTM E2297 and MIL-STD-271E, as no visible light is emitted while ultraviolet light passes unrestricted. Thus, it can be relied upon for FPI and MPI procedures.

- Lightweight, Durable Construction & Cordless

Due to its aluminum casing, the flashlight is lightweight, and powered by a rechargeable Li-ion battery, it is completely cordless and offers 6 hours of continuous use. This durability makes the UV100-N ideal for field inspections.

- Constant Battery Level Check and Peak Performance

Visual performance indicators ensure that peak performance is maintained with no guessing needed to determine when charging is required. The UV100-N is equipped with an LCD charger that displays current battery levels and provides fast charging.

Most Common Uses of 365nm UV Light Inspection

Industries often utilize 365nm UV Inspection Light for the following:

1. Non-Destructive Testing (NDT)

Through fluorescent penetrant testing (FPT) or magnetic particle inspection (MPI), evaluation work performed on components often goes undetected with normal illumination. Parts can be carefully examined for cracks or inclusions using fluorescent dyes with 365nm UV light without any damage. This aids in maintaining product safety and quality.

2. Leak Detection

Automotive coolant, HVAC refrigerant, and industrial fluid leaks can be diagnosed using 365nm UV lights as they magnify fluorescent dyes. The fluids leaking fluoresce, thus enabling technicians to swiftly identify the concealed issues. This leads to reduced downtimes and repairs.

3. Forensic Analysis

365nm UV lights are useful in forensics for detecting bodily fluids, body parts, and fake documents in crime scenes. The same goes for all types of counterfeiting detection. Pure UV light assists greatly in accuracy while gathering evidence.

4. Restoration of Art & Mineralogy

UV light is used by art conservators to check for retouched sections as well as to reveal layers of the artwork that have been hidden. Geologists, on the other hand, use 365nm UV to identify certain minerals due to their distinctive fluorescent signature, which aids research and authenticity of the specimens.

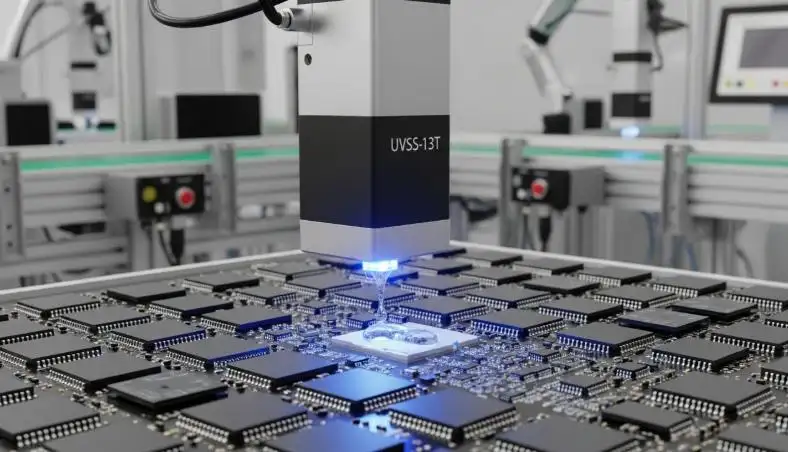

5. Cleanrooms & Inspection of Contamination

For professionals in the pharmaceutical and electronics manufacturing industries, 365nm UV inspection lamps are crucial to hygiene and residue and contamination checks as they help maintain invisibly high standards of electronics contamination.

Choosing the Best 365nm UV Inspection Light

The following are key criteria for choosing devices:

- Purpose & Application: NDT, automotive, diagnostic, forensics, or art inspection.

- Wavelength Authenticity: Ensure it does not mix with visible violet light.

- Intensity & Beam: High power for larger area inspections; intricate work requires focused beams.

- Battery & Portability: Field work may need rechargeable batteries.

- Durability: Select units with IP-rated rugged construction for outdoor or extreme environments.

- Accessories: Wearing UV protective glasses, fluorescent dyes, and calibration meters enhances efficiency.

Benefits of Using 365nm UV Inspection Lights

- Improved Precision: Defect recognition is more efficient owing to higher fluorescence contrast.

- No Damage: Inspections can be performed without causing any damage to the parts or surfaces.

- Productivity: Swift detection of leaks or flaws reduces inspection time.

- Reduce Costs: Early detection of issues significantly reduces expensive repairs or recalls.

- Industry Acceptance: Used in aerospace, automotive, manufacturing, and forensics industries.

Conclusion

A 365nm UV inspection light goes beyond being just a flashlight; it transforms how inspections are conducted. Its applications range from simple fluorescent inspection UV tasks to intricate non-destructive testing where unwavering precision and reliability are essential. Choosing the proper 365nm UV LED light for your application increases precision during detection, saves time, and reduces costs. For professionally supported devices, turn to UVET to purchase UV inspection devices.