Smart UV LED Curing for Every Surface

Full Area, Full Power — Instantly Cured

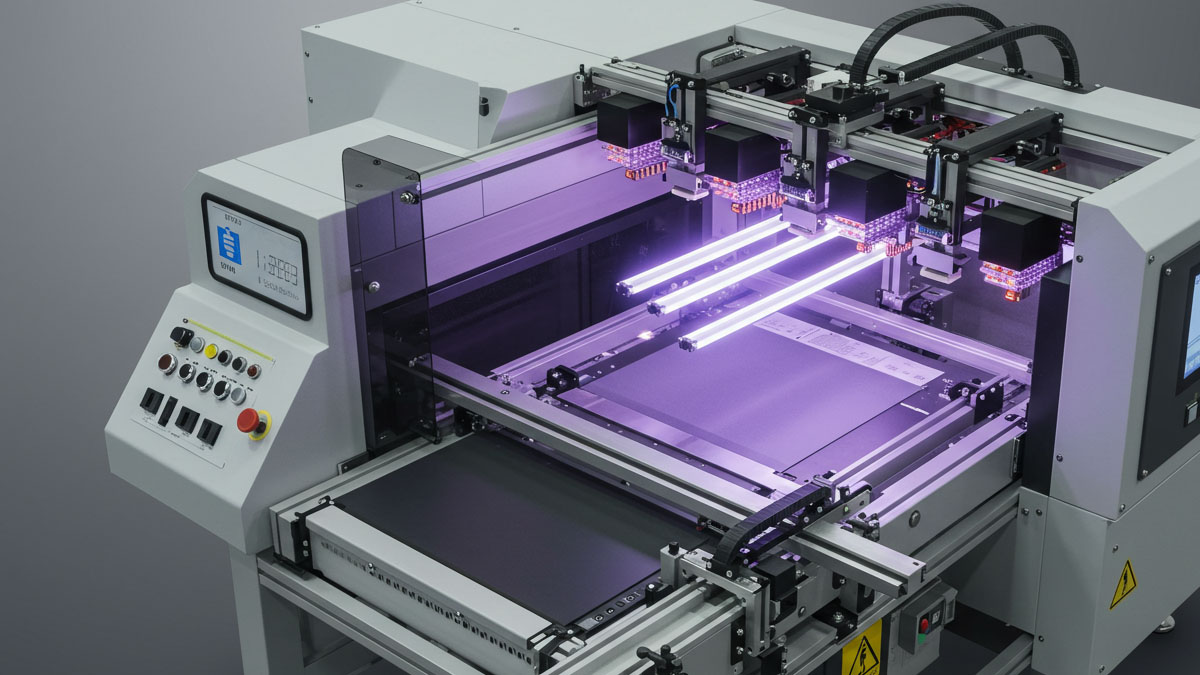

The ‘UV LED Area curing System’ offers a powerful solution for wide area ultraviolet curing of UV exposed materials. It offers high accuracy focusable LED technology which yields high intensity UV radiation over a broad surface area which is preferred in complex production lines and accurate fabrication processes.

-

UV LED Linear Curing Unit

- Irradiation Area: 120x10mm

- Intensity: 5W/c㎡ @365nm

- 6W/c㎡ @385/395/405nm

Learn More -

UV LED Linear Curing Light

- Irradiation Area: 300x10mm

- Intensity: 4W/c㎡ @365nm

- 5W/c㎡ @385/395/405nm

Learn More -

UV LED Spot Curing Machine

- Irradiation Area: 20x20mm

- Intensity: 3500mW/c㎡ @365nm

- 4200mW/c㎡ @385/395/405nm

Learn More -

UV LED Curing Lamp

- Irradiation Area: 50x30mm

- Intensity: 3500mW/c㎡ @365nm

- 4200mW/c㎡ @385/395/405nm

Learn More -

UV LED Curing Unit

- Irradiation Area: 60x60mm

- Intensity: 2500mW/c㎡ @365nm

- 3000mW/c㎡ @385/395/405nm

Learn More -

UV LED Curing Light

- Water Cooling

- Irradiation Area: 90x90mm

- Intensity: 6W/c㎡ @365nm

- 8W/c㎡ @385/395/405nm

Learn More -

UV LED Curing Light Source

- Irradiation Area: 100x100mm

- Intensity: 2500mW/c㎡ @365nm

- 3000mW/c㎡ @385/395/405nm

Learn More -

UV LED Curing Equipment

- Irradiation Area: 150x50mm

- Intensity: 2500mW/c㎡ @365nm

- 3000mW/c㎡ @385/395/405nm

Learn More -

UV LED Flood Curing Lamp

- Irradiation Area: 150x100mm

- Intensity: 1500mW/c㎡ @365nm

- 1800mW/c㎡ @385/395/405nm

Learn More -

UV LED Flood Curing Device

- Irradiation Area: 150x150mm

- Intensity: 1500mW/c㎡ @365nm

- 1800mW/c㎡ @385/395/405nm

Learn More -

UV LED Flood Curing System

- Irradiation Area: 200x200mm

- Intensity: 1500mW/c㎡ @365nm

- 1800mW/c㎡ @385/395/405nm

Learn More -

UV LED Flood Curing Machine

- Irradiation Area: 250x250mm

- Intensity: 1500mW/c㎡ @365nm

- 1800mW/c㎡ @385/395/405nm

Learn More

Key Features of Our UV LED Area Curing

-

as 50×50mm, 100×100mm

-

Available in 365nm, 385nm, 395nm

-

LED Lifespan:≥20,000 hours

-

AC 110–240V, 50/60Hz

Let us partner with you to create solutions that drive innovation, efficiency and success in your industry!

Technical Specifications (Sample):

| Specification | Detail |

|---|---|

| Curing Area | 50×50mm / 100×100mm / Customizable |

| Wavelength Options | 365nm / 385nm / 395nm / 405nm |

| UV Intensity | Up to 3000 mW/cm² (model-dependent) |

| Cooling Method | Air or water cooling |

| Control Modes | Manual / External trigger / PLC-compatible |

| Power Input | AC 110–240V, 50/60Hz |

| LED Lifespan | ≥20,000 hours |

| Housing Material | Aluminum alloy, industrial-grade |

UV LED Area Curing – FAQ

1. Q: How do I choose the correct wavelength?

A: Different adhesives, inks, and coatings formulated for UV curing respond optimally to specific wavelengths:

-

Deep curing 365nm

-

General-purpose applications 385nm / 395nm

-

Fast surface curing 405nm

Please check the manufacturer’s datasheet for optimal selection.

2. Q: Is it possible to customize the curing area?

A: Certainly. Depending on the customer’s product and production needs, the system can be tailored to different curing area sizes such as 50×50mm, 100×100mm, or 200×200mm.

3. Q: How long do UV LEDs usually last?

A: Compared to traditional mercury lamps, the LED modules outlive them by offering over 20,000 hours of usage, in addition to providing better reliability and requiring minimal upkeep.

4. Q: Can the System be used with Automated Systems?

A: Certainly. The greater part of area uv led curing systems accept PLC interface and external trigger options, which facilitates their use into automated production lines or robotics.

5. Q: What is the suggested safety concern, if any, for use of UV LED systems?

A: Compared to mercury lamps, UV LED’s pose a lesser threat, however, as with all sources of UV radiation, there are risks to eyesight and skin.

Avoid looking directly at the light source and use UV-filtering protective glasses.

(2).png)