UV LED Inspection Lights – Precision, Durability, and Clarity

Advanced UV LED light sources for non-destructive testing (NDT) in critical industries

With a focus on aerospace, automotive, and manufacturing technologies, industries ranging from construction to medicine can benefit from immediate activation, warm-up free operation, and consistent power emission provided by LED solutions. These features, when coupled with the 365 nm to 395 nm wavelength, strengthen images captured through FPI and MPI techniques, reinforcing NDT in CNC technology.

-

UV LED Torch for NDT

- Wavelength: 365nm

- UV Beam Size: Φ40mm

- Peak Intensity: 40000µW/cm2

Learn More -

UV LED Light for NDT

- Wavelength: 365nm

- UV Beam Size: Φ100mm

- Peak Intensity: 15000µW/cm2

Learn More -

UV LED Inspection Lamp

- Wavelength: 365nm

- UV Beam Size: Φ150mm

- Peak Intensity: 6000µW/cm2

Learn More -

UV LED Lamp for NDT

- Wavelength: 365nm

- UV Beam Size: Φ170mm

- Peak Intensity: 4500µW/cm2

Learn More -

UV LED Inspection Headlamp

- Wavelength: 365nm

- UV Beam Size: Φ40mm

- Peak Intensity: 40000µW/cm2

Learn More -

UV LED Inspection Tool

- Wavelength: 365nm

- UV Beam Size: Φ100mm

- Peak Intensity: 15000µW/cm2

Learn More -

UV LED Inspection Light

- Wavelength: 365nm

- UV Beam Size: Φ170mm

- Peak Intensity: 8000µW/cm2

Learn More -

Pistol Grip UV Inspection Lamp

- Wavelength: 365nm

- UV Beam Size: Φ250mm

- Peak Intensity: 4000µW/cm2

Learn More

Key Features of our LED UV Inspection

-

High-Intensity UV-A Illumination

-

Dual-Light Functionality

-

Rugged and Portable Design

-

Compliance with Industry Standards

Partner with us to develop LED UV Curing solutions that power innovation, maximize efficiency, and drive success across your industry!

Applications

-

Non-Destructive Testing (NDT): Widely used in fluorescent penetrant inspection (FPI) and magnetic particle inspection (MPI) for the aerospace, automotive, and manufacturing sectors.

-

Quality Control: Detection and confirmation monitoring of uniform coatings, adhesives, and sealants, as well as contamination on surfaces and components.

-

Verification of Cleanliness: Useful in identifying residues and contaminants in cleanroom spaces and verifies conformance to stringent cleanliness standards.

-

Detection of Counterfeits: Document, currency, or product verification is simplified by detection of counterfeit items through security features visible under UV light.

How to Choose the Right LED UV Inspection System

1. Determine Your Application

-

Molding/Shaping/Drilling/Turning Processes – Inspection and verification of produced parts for flaws

-

Non-Destructive Testing – magnetic particle inspection (MPI), fluorescent penetrant inspection (FPI)

-

Counterfeit detection for security features in documents or packaging

Assessing different applications will help achieve the appropriate intensity levels, beam dimensions, and safety standards for certification required.

2. Verify the UV Wavelength

-

For inspections, 365 nm (UV-A) is most widely accepted.

-

For the inspection of fluorescent materials, ensure the lamp produces minimal visible light to avoid interference.

3. Evaluate UV Irradiance and Geometric Coverage

-

Inspections with high-intensity output (e.g., over 1,200 μW/cm² at 15 inches) are faster and more effective.

-

If large surfaces must be assessed, look for systems with a broad uniform beam.

-

A narrow focused beam is best for small areas and detailed inspections.

4. Look for Certification and Compliance

Confirm the system meets the following certifications (if applicable) to the business sector’s compliance:

-

ASTM E3022

-

ISO 3059

-

Rolls-Royce RRES 90061 (if aerospace applicable)

These certifications assure dependability and eligibility for regulated environments.

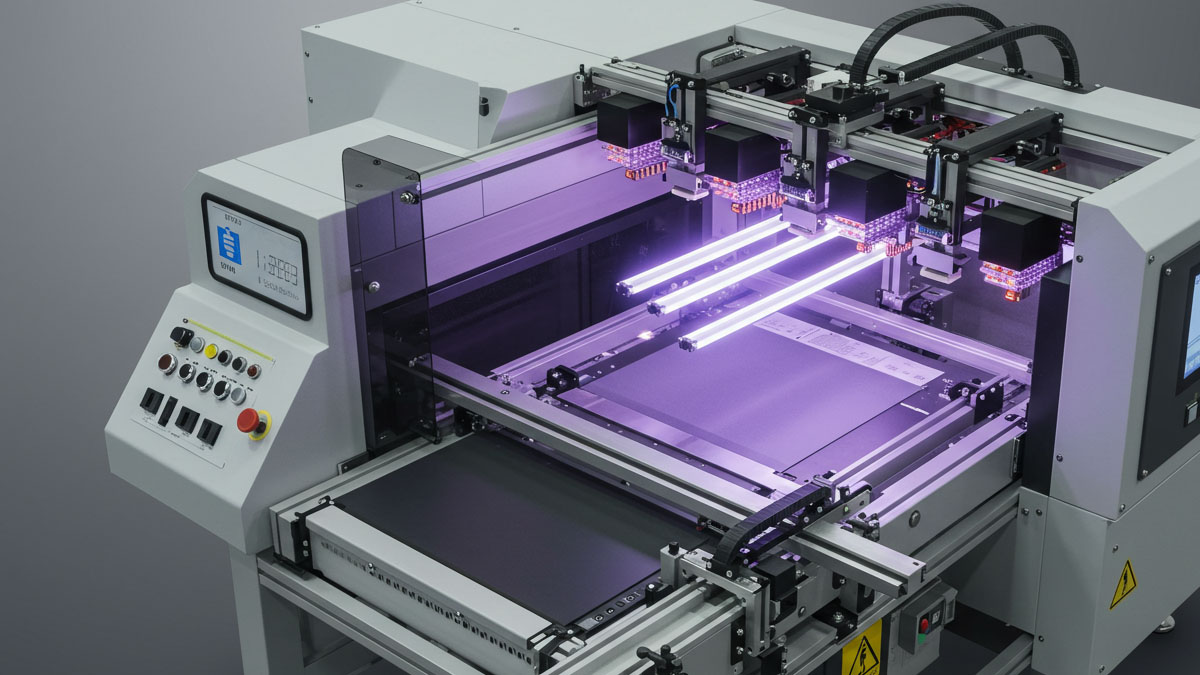

5. Consider Portability Versus Stationary Use

-

Handheld: Light-weight instruments are powered by batteries for mobility or field examinations.

-

Stationary/bench-top: More powerful instruments better suited for laboratories or production environments.

6. Check for Capability of Dual Light Source

-

Some systems equipped with UV LEDs and white light LEDs offer toggle capabilities for switchable modes during inspection and documentation.

7. Structural Performance and Environmental Adaptability

-

Ensure enclosures with IP ratings (IP65 for instance) are protected from dust, water, and other rugged environments.

-

Choose materials that are resistant to impacts when working in industrial or field settings.

8. Other Considerations

-

Built-in cooling systems for extended use

-

Light adjustability

-

Battery life for portable models

-

Ergonomics of contour, weight, and design

-

Warranty terms and support for services after purchase

📌 Summary Checklist

| Feature | Recommendation |

|---|---|

| UV Wavelength | 365 nm (UV-A) |

| UV Intensity | ≥1,000 μW/cm² at 15 in (varies by need) |

| Certification | ASTM E3022, ISO 3059, etc. |

| Beam Profile | Uniform and wide or focused, as needed |

| Portability | Handheld for field, fixed for lab/line use |

| Additional Functions | White light, intensity control, cooling |

| Durability | IP-rated, rugged housing |