Advanced UV LED Curing Chambers for Consistent Results

Features intelligent temperature regulation and adjustable UV output, providing high repeatability and minimal deviation—ideal for labs and production environments.

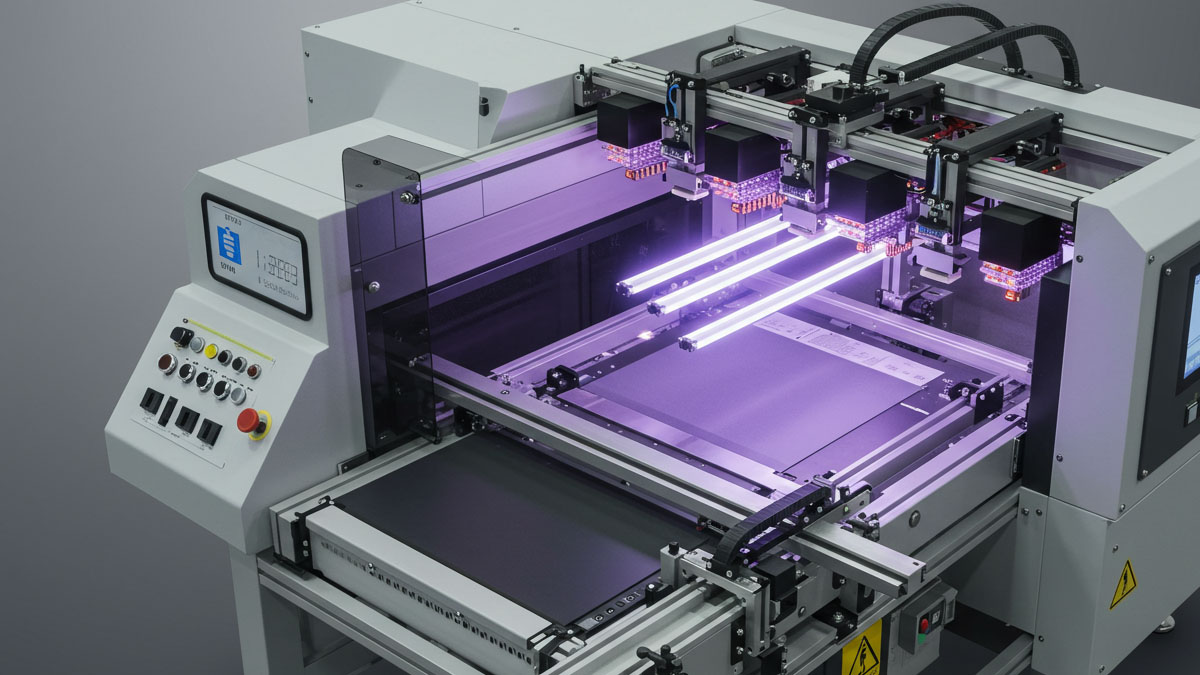

UV LED Curing Chambers are automated curing systems for ultraviolet (UV) curable materials that require precise and intense UV light exposure. They are shielded from heat damage because of their advanced led technology, which provides fast curing while heat exposure remains at a minimal level. The fully enclosed chambers block internal UV light leakage, enhancing user safety, while additional internal UV reflectors improve light uniformity and distribution. They are often used for curing coatings, adhesives, inks, and resins used in 3D printing. The chambers set and provide reliable outputs for consistent and programmable timers, adjustable intensity settings, and multiple selected wavelength options ranging from 365nm to 405nm. They can also be relied on for consistent, efficient curing in laboratories, production lines, and R&D settings.

Typical Applications of our UV LED Curing Chambers

-

UV adhesive curing for electronic components

-

Medical device bonding and sealing

-

Post-curing of 3D printing resins

-

Lab-scale curing of UV inks and coatings

-

Optical component bonding and encapsulation

Partner with us to deliver UV LED Curing Chamber solutions that power innovation, boost efficiency, and accelerate success in your industry.

The UV LED Curing Chamber is enclosed and self-contained multifaceted ultraviolet curing device which gives safety and uniform curing of materials such as adhesives, inks, coatings, and 3D printing resins. The device uses a modern LED technology which consumes low energy, offers a long service life, And instant performance which is ideal for R&D as well as small scale production.

Reflective materials ensure uniform exposure while the sealed enclosure contains UV light for operator safety. The system also contains programmable timers and set parameters for the wavelengths of interest, 365nm, 385nm, 395nm, 405nm.

How to Choose the Right UV LED Curing Chambers?

To an extent, all chambers serve the same purpose thus, all serve various applications. To better understand what you may require, here is a guide to assist you:

1. Identify Your Application

Check what requires curing.

- UV adhesives: Require precise timing during application.

- 3D printing resins: Require careful exposure and low heat to reduce risk of warping.

- Coatings or inks: Depending on need can take advantage of large chambers and high UV intensity.

Each chamber differs on design features thus it important to match versatility of the chamber to your use case.

2. Choosing the Right Wavelength

In the case of UV LED curing chambers, the offering wavelength is like:

- Deep curing and ideal for some adhesives is 365nm

- General-purpose curing is at 385/395nm

- Surface level and faster curing or commonly used for 3D resins is at 405nm

Always remember to check the material’s datasheet to ensure selecting the preferred wavelength.

3. Think About Chamber Size Along With Its Capacity

- Small desktop units are good for lab use and prototyping

- Mid to large chambers work better for batch processing, or several parts at the same time.

- Avoid going for oversized options but rather, choose one that comfortably fits the parts.

4. Assess Light Uniformity

- Lack of uniform UV light distribution is critical for over or under curing

- Look out for chambers with reflective inner walls or LED arrays that are multidirectional

- Make sure the chamber provides exposure that is 360° or has turntable support.

5. Pay Attention To The Following Details:

- Programmable timers to ensure curing time is always consistent

- Adjustable intensity for more delicate materials that require exposure fine-tuning

- Safety interlocks & UV blocking windows for the operator’s safety

- A cooling system is crucial for extended curing cycles

6. Support and Reliability

Ensure the brand has reliable reputation with these factors:

- Technical support along with documentation provided

- Parts that are easily replaceable or modular designs

- Covered under warranty along with safety certifications and certification marks