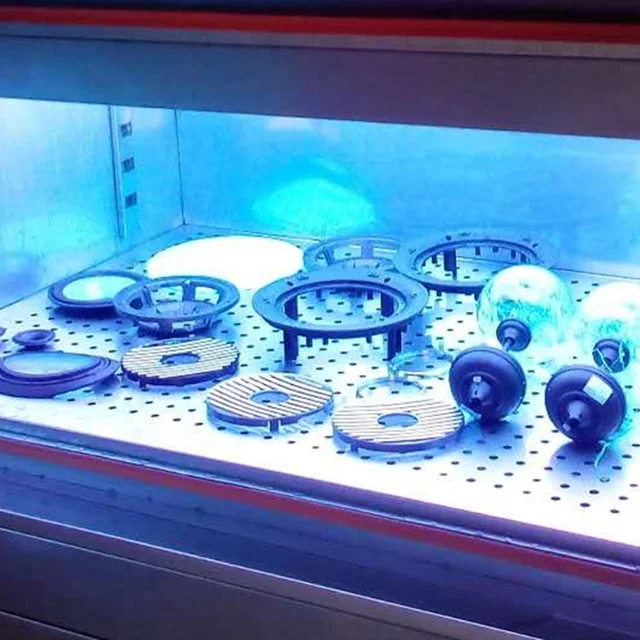

UV LED Curing Oven

- Model: CS180A

- Various Sizes

UVET’s UV LED curing ovens are available in a variety of sizes and are designed with built-in reflectors to ensure uniform UV exposure for reliable and efficient curing. The system is equipped with high-intensity UV LED lamps with adjustable UV power and working distance to meet various process needs. This curing oven improves production efficiency and supports fast and consistent curing results.

Specifications

| Part No. | CS180A |

| Inside Dimensions | 180(L)x180(W)x180(H) mm |

| Outline Dimensions | 230(L)x230(W)x230(H) mm |

| Working Status | Visible via anti-UV leakage window |

| Operation | Close the door:The UV LED lamp starts working automatically. Open the door during irradiation: The UV LED lamp stops immediately. |

-

Descriptions

UV LED Curing Oven supports a variety of curing applications including bonding, sealing, and coating of optical components such as lenses, filters, prisms, and fiber assemblies. Whether integrated into small-scale labs or large-volume production environments, the UV LED curing oven offers scalable performance with precision and consistency.

These ovens are available in a range of chamber sizes and configurations to accommodate diverse production workflows. From benchtop setups for prototyping to fully automated systems in high-throughput manufacturing lines, each curing oven is optimized for even UV distribution across the work area. This ensures reliable curing results regardless of component geometry or placement.

Application

UV LED Area Curing Lamp for Optics in Lab Materials Research

UV LED area curing lamps are primarily used in materials research labs, especially in the research and development of optical components. These lamps are often used to cure and irradiate glues, adhesives, coatings, and electronic materials – processes that enhance material properties and improve the reliability of prototypes and experimental models.

Key Applications:

- Performance Testing: Used to evaluate how materials respond to curing and UV irradiation, helping researchers assess product performance and durability under controlled conditions.

- Repeatable results: Ensure consistent and repeatable results during paper or material testing, facilitating validation of findings and maintaining experimental integrity.

- Safe Research Environment: Supports a clean, stable, and safe laboratory setting, enabling detailed and accurate scientific investigations without the risks associated with traditional curing systems.

UV LED Area Curing Lamp in Rapid Prototyping

UV LED area curing lamps offer a powerful solution for rapid prototyping, especially for 3D-printed parts. These systems cure materials quickly and efficiently, testing and validation take less time.

Key Benefits:

- Fast Curing of 3D-Printed Parts: These lamps speed up the hardening process. You can test and evaluate prototypes shortly after printing.

- Thorough Prototype Evaluation: The system allows teams to inspect and refine multiple iterations with ease. This helps improve design accuracy and functionality.

- Improved Quality with Adhesives and Sealants: UV LED curing strengthens bonds and seals. It ensures prototypes are durable, reliable, and production-ready.

UV LED Area Curing Lamp in Electronic Component Production

UV LED area curing lamps to enhance the production of electronic components. These systems cure adhesives, encapsulants, and surface coatings quickly and accurately. As a result, components remain securely bonded and protected, ensuring reliable long-term performance.

Key Benefits:

- Accurate Material Placement: The curing process keeps adhesives and encapsulants in place, preventing shifts or deformation during production.

- Improved Durability: UV curing strengthens the structural integrity of components, which boosts their performance and extends their lifespan.

- Consistent Assembly Quality: Reliable curing helps maintain high assembly standards.

-

FAQs

Q1: What is the purpose of a UV LED curing oven in industrial applications?

A: A UV LED curing oven provides controlled, high-efficiency curing of UV-reactive materials such as adhesives, inks, and coatings.Q2: How does a UV LED curing oven improve upon traditional UV curing systems?

A: Compared to mercury-based systems, UV LED ovens deliver cooler, more energy-efficient curing with instant on/off functionality, longer operational life, and environmentally responsible performance without ozone or hazardous materials.Q3: Which materials are compatible with UV LED curing ovens?

A: These ovens effectively cure a wide range of UV-sensitive materials, including acrylate adhesives, conformal coatings, varnishes, and UV inks on substrates such as plastic, metal, glass, and composites.Q4: What wavelength options are available for UV LED curing ovens?

A: Standard options include 365 nm, 385 nm, 395 nm, and 405 nm, selected to match the photoinitiator chemistry of the UV formulation to ensure consistent, deep, and rapid curing results.Q5: What key features should a high-performance UV LED curing oven offer?

A: Uniform irradiance across the curing zone, precision intensity and exposure control, advanced thermal management (air or water cooling), safety interlocks, and options for PLC or conveyor integration.