How Do UV LED Modules Work? Understanding UV LED Technology

What is a UV LED?

Ultraviolet light-emitting diodes (UV LEDs) are examples of semiconductor-based electronic devices that generate ultraviolet light (UV) radiation as a result of passing an electric current through them. Unlike incandescent and fluorescent lamps, UV LED emitters are more robust and energy efficient since they do not have any moving elements.

Core Functionality & Scientific Principles

The introduction of new technologies has practically made UV LEDs useful for many different purposes. These include printing, medical sterilization, water treatment, etc. In this post, we will look at the science, design, performance, and application of UV LED modules.

How Do UV LEDs Emit Light?

- How do UV LED modules work? Activation of an electric current enables electrons to stream to the n-type section of the semiconductor and holes to the p-type section. Both these charge carriers meet at the P-N junction, where the recombination takes place. This process is called electroluminescence. During the recombination phase, energy is given off in the form of light particles.

- The emitted UVA, UVB, or UVC light types are associated with the wavelength of light and the materials used for the LED. Bandgap energy, the difference in energy between the conduction band and the valence band in semiconductor materials, determines the wavelength. Shorter wavelength photons, such as ultraviolet, are produced with a greater band gap.

Semiconductor Materials Used in UV LEDs

• AlGaN (Aluminum Gallium Nitride): Ideal for emitting deep UVC radiation (200–280 nm). Provides high thermal stability and photon efficiency.

• GaN (Gallium Nitride): Used for UVA and UVB range emissions because of its strength and high electron mobility.

• InGaN (Indium Gallium Nitride): Can be tailored to emit specific wavelengths, providing customization for certain applications.

These materials help engineers optimize UV LEDs for various industrial and scientific uses.

Components & Design of UV LED Modules

- UV LED Chip

The chip is the basic component that produces UV light. Its mounting is done on sapphire or AlN, which serves as a substrate. To enhance protection and light extraction, encapsulation is often used.

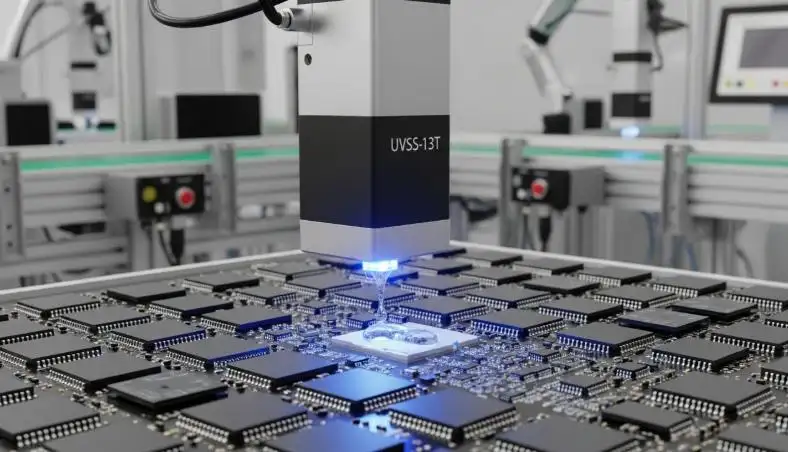

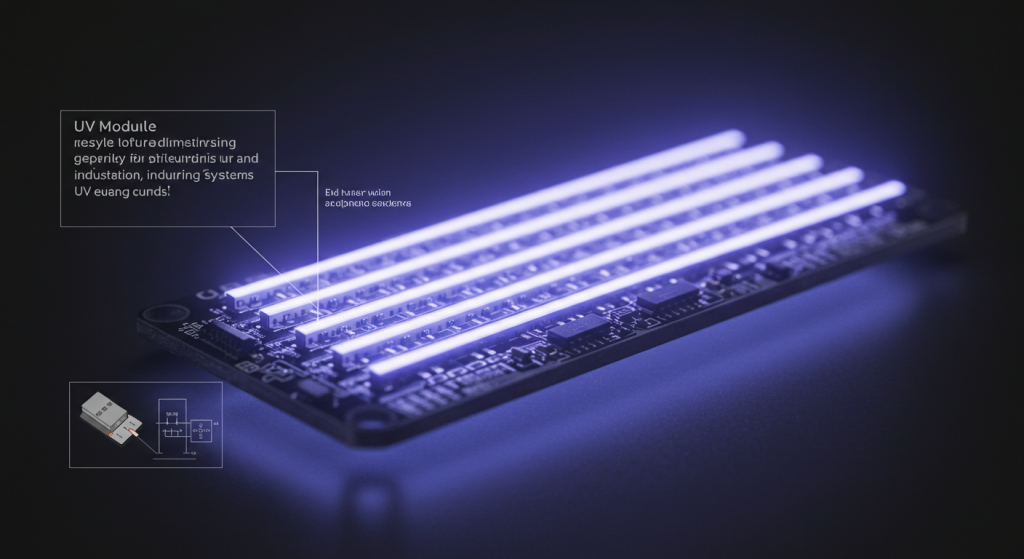

- UV LED Array

This device is made up of individual ultraviolet LED chips that are strategically placed to increase irradiance levels. For some applications, high intensity and uniform exposure to ultraviolet light across its surface is critical, and arrays are well suited for this purpose.

- UV LED Module

A full unit is built that encapsulates the individual chip or array of the LED with its associated optics, thermal management components, and driver circuitry. Modules are usually built as aids for specific functions like curing, sterilization, or inspection.

- Packaging & Thermal Management

Proper packaging provides mechanical stability and assists in heat dissipation. Examples include TO-39 packages and surface mount designs. Good thermal management is particularly crucial in this case because UV LEDs generate a lot of heat, which can negatively affect the performance and lifespan of the device.

- Driver Circuit

This is the electronic device that provides power to the LED and ensures it is functioning consistently. It also protects the LED from power surges and drops in voltage.

Performance & Characteristics

- Efficiency Metrics

• Wall-Plug Efficiency (WPE): Measurement of optic power output in comparison with the electrical power input.

• External Quantum Efficiency (EQE): A ratio of electrons capable of triggering the emission of a photon.

Different levels of light output for UV LEDs can be measured in milliwatts (mW). The term irradiance refers to the UV light intensity in a specific area and is measured in mW/cm².

- Lifetime & Reliability

Quality UV LEDs tend to last over twenty thousand hours, but such adversities as poor thermal management and low-quality materials can negatively impact longevity.

- Instant On/Off & Dimming Capability

In many situations, UV LEDs can provide instant light and, in certain cases, dimmed illumination, making them versatile for different environments.

Applications & Use Cases

- UV Curing

The capability of UV LEDs to quickly harden inks, coatings, adhesives, and resins makes these materials easier to work with. High-intensity UV lights increase production speed while saving energy, making their use in curing materials very common.

- UV Disinfection

As an example, UVC LEDs emitting approximately 275 nm wavelengths are essential for inactivating bacteria and other pathogens. This makes them important for water purification, air sterilization, and surface decontamination.

- Medical Sterilization

In the medical field, UV LEDs aid in instrument and surface sterilization, helping maintain hygiene standards.

- Industrial Applications

Certain industrial applications, such as counterfeit, forensic, and DNA analysis, utilize UV LEDs as they induce fluorescence in specific materials.

- Horticulture

With Controlled Environment Agriculture, UV LEDs are used to encourage plants to grow and improve their health and defenses against diseases and pests.

UVET is the Best Provider

UVET is among the top producers of UV LED curing systems and offers a full range of solutions for printing applications. Focused on innovation and engineering excellence, our systems are designed to meet the most demanding challenges in the industry. Our technology is integrated with strong R&D, sales, and technical support teams, which ensure that every product complies with international standards for quality, safety, and dependability.

- Commitment to Excellence

At UVET, excellence is a commitment rather than a goal. Our teams work to optimize productivity, energy, and print efficiency for the benefit of the customer. Custom-tailored services provided through focus groups guarantee that customers achieve optimal results in varying printing environments.

- Customer-First Philosophy

We embrace a customer-first strategy that aims to reinforce strategic alliances grounded in trust, collaboration, and mutual expansion for all parties involved. From the first meeting to system customization, integration, training, maintenance, and after-sales care, customers receive complete service at every stage of the customer journey.

- Your Reliable Partner

Achieving these goals requires us to shift focus from just selling high-performance UV LED technologies to building enduring partnerships. With UVET, you gain a reliable partner who supports you in meeting your objectives today and for years to come.

Conclusion

How do UV LED modules work? The compact and energy-efficient nature of UV LED modules makes them essential in various fields and industries. Furthermore, they are multifunctional. All industries intending to use UV light for curing or disinfection need to understand the operations, design, and advantages of UV modules. Visit UVET.