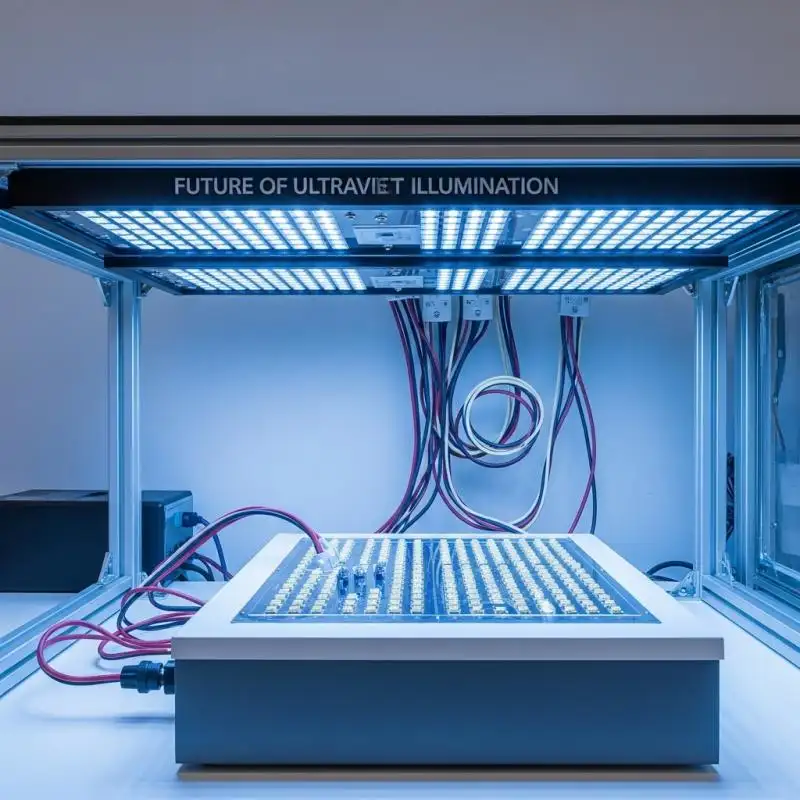

How to Choose the Right UV LED Module for Curing? 2025 Guide

How to Choose A UV LED Module for Curing?

Like any other important innovations in Industrial manufacturing, the use of UV LEDs for curing has enhanced technology. Also, if you are dealing with adhesives, inks, coatings, or even 3D printing resins, you need to select the right LED module for maximum effectiveness and efficiency. This guide addresses all the relevant technical considerations as well as practical factors that you need in choosing the UV LED module.

Understanding UV LED Curing Technology

How to choose the right UV LED module for curing? UV LED curing technology is the use of ultraviolet light to activate a photochemical reaction on UV-sensitive materials. Unlike mercury lamps, UV LEDs are a lot more eco-friendly and energy-efficient, which also gives better control over the curing process.

1. Key Selection Criteria for UV LED Modules

Your use case will determine which UV LED module best suits you. The following selection criteria will help you guide the most important of these 6 key criteria:

2. Wavelength Compatibility

Wavelength directly affects the speed and efficiency of the material to be curable. Most applications of curing by UV LEDs are in the UV-A range: 365nm, 385nm, 395nm, and 405nm. Each material, including UV curable inks, adhesives, and coatings, has its specific photoinitiators that respond to the specific wavelength range

- 365nm: This one works best for getting deep into thick layers and curing them.

- 395nm or 405nm: These are good for faster processes and surface curing.

3. Intensity and Dose

These two metrics are important when evaluating the effectiveness of UV curing:

• Irradiance (W/cm²): The amount of power received at the surface at a specific moment in time.

• Dose (J/cm²): Energy that accumulates over time.

Curing speed improves with higher irradiance, but a careful shot and steady dose avoid under- or over-curing. Look for adjustable settings for stable output to ensure consistent production.

4. Beam Profile and Uniformity

To achieve even light for even curing, consider the following:

- For sharp and narrow curing, use collimated UV LED modules.

- For large-format printing or coatings that need wider coverage, use wide-angle modules.

- Poor uniformity can lead to surface tackiness, incomplete cures, or other product defects.

5. Working Distance

The distance between the module and the substrate affects the depth of curing, as well as the working distance impacts clearing. Modules with a deep focus are helpful in situations where alignment is not precise. As with all LEDs, the ability to maintain irradiance at a distance is critical.

UVET: Your Dependable Source for High-Efficiency UV LED Modules

How to choose the right UV LED module for curing? When it comes to cutting-edge LED ultraviolet modules for curing, sterilization, or precision inspection, UVET is your go-to. Their OEM-compatible modules from 265nm to 405 nm are unrivaled in spectral flexibility and performance.

- Custom Wavelength Solutions

Selecting ideal wavelengths for certain applications, like 265 nm for sterilization, 365nm for curing adhesives and coatings, or 405 nm for printing and electronics, is crucial. Each application is tuned with photoinitiators for optimal performance to enable fast and deep cures. Output irradiance levels of 15W/cm² are consistently maintained, which is unmatched in high-throughput environments.

- Streamlined System Integration

Plug-and-play convenience is provided through preset optical lenses with integrated drivers and heat sinks. These modules offer automation-ready PWM and TTL controls for precise power modulation.

- Engineered for Efficiency

Ultraviolet LED modules with patented energy-efficient thermal management systems reduce energy consumption. The downtime is greatly reduced with over 20,000 operational hours and 40% savings on cooling costs. UVET offers dependable, scalable, and energy-saving UV LED options for industrial curing lines and compact medical devices.

Cooling Systems and Thermal Management

UV LEDs need to be thermally managed because overheating can reduce performance and shorten the usable lifespan.

- Air-Cooled UV LED Modules

• Easier to install.

• Best fit for low to medium power configurations.

- Water-Cooled UV LED Modules

• More suited for higher power applications.

• Offers precision temperature control.

- Form Factor and System Integration

UV LED modules come in various shapes and sizes:

• Compact modules serve best in small installs.

• Modular designs have no upper limit to scaling.

• Ensure compatibility with the production line.

- Use Case Customized Requirements

Each application is unique.

• Requires spot curing control.

• Must be low to avoid deformation.

- UV LED Curing For Coatings

• The beam must be wide and uniform.

• High intensity is required for thicker coatings.

Advantages of Utilizing UV LED Curing Modules

UV LED curing systems offer additional benefits over conventional UV lamps:

• Economic – Requires lower overall energy expenditure and heat output.

• Mercury-free and ozone-free make it environmentally friendly.

• Higher durability than average, lasting over 20,000 hours.

• Instant activation and no warm-up required.

• High Accuracy – Adjustable brightness settings, real-time feedback logs, and high granularity control.

Streamlined production reduces downtime, which improves operational efficiency.

Measurements and Assessment of Performance

Optics as a System with Elements

- The overall stability and brightness of a device are determined by the quality of the LED chip.

- Beam intensity and profile, for example, are affected by the lenses.

Performance measurement criteria radiate over the lifetime of a UV LED device, and output degradation must be monitored over time.

- Process consistency relies heavily on precision control: intensity stability.

Other Considerations

- Modules should be designed for ease of retrofitting or integration.

- Seek custom UV LED modules where necessary.

Cost Considerations and ROI

Even though UV LED systems may require a larger initial investment, they save in the long run through:

• Lower spending on energy

• Little maintenance needed

• Less waste of materials

• Increased productivity

ROI Factors

• LED lifetime vs. traditional bulbs

• Led related downtime reduction

• Improvements in material compatibility

Vendor Selection and Customization

When looking for UV LED curing modules, make sure to check their:

• Customer service and after-sales care

• Experience in industrial applications

• Custom UV LED module design capability

Conclusion

How to choose the right UV LED module for curing? The technical choice that impacts efficiency, quality, productivity, and environmental footprint is the module selection for curing. Assess materials compatibility and make informed judgments on choosing wavelength, irradiance, application-specific requirements, thermal control, and integration. UVET offers high-performance, customizable UV LED curing modules for diverse industries.