Industrial UV LED Light Module: Features, Benefits & Uses

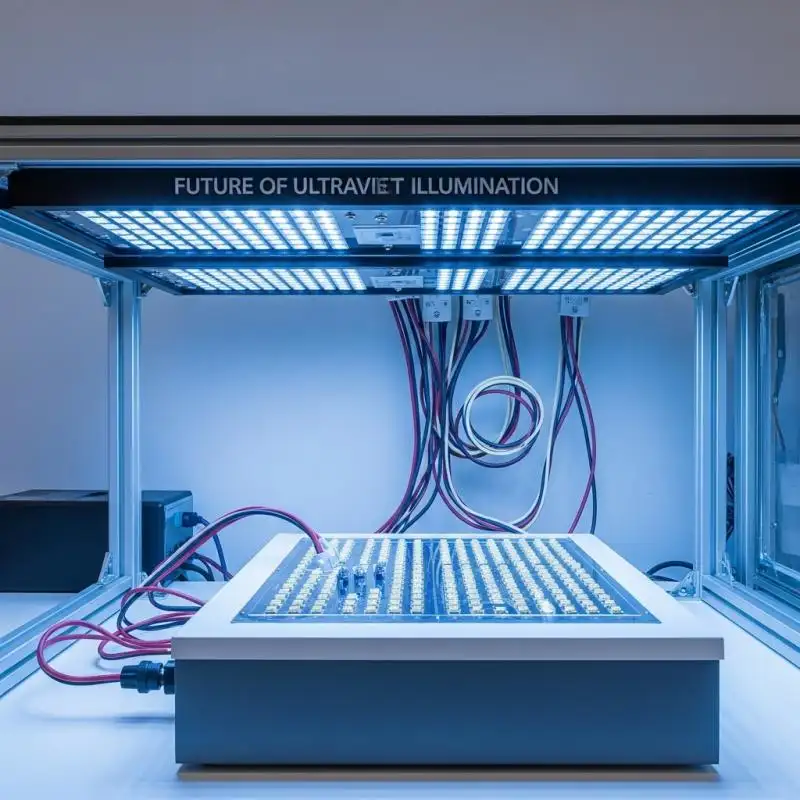

What is an Industrial UV LED Light Module?

- Industrial UV LED light module is a compact lighting system engineered to emit and irradiate specific ultraviolet (UV) light spectra such as UV-A (320-400 nm), UV-B (280-320 nm), and UV-C (100-280 nm). These are especially useful in surgery while also minimizing pollution in emitted ultraviolet (UV) light.

- Traditional mercury vapor lamps have become outdated due to their lack of efficiency. The UV LED modules now have no mercury, are more cost-effective, safer, and more efficient, and have longer lifespans. Furthermore, they are industrial-friendly as they can be switched on and off instantly.

COB UV Modules for Industrial Applications of UV LED Lights

Due to the strong and even illumination, these COB (Chip-on-Board) UV LED modules emit, they are ideal for industrial UV LED light systems. These modules can be customized to emit wavelengths of 365nm, 385nm, 395nm, and 405nm, which makes them useful for over forty different applications across many industries. Furthermore, these modules are convenient for laboratories and industrial production lines because of their small size and compact thermal management.

Key Features

- High Power Density: With the COB packaging, light output increases because of higher power density and efficient area yield.

- Custom Wavelength Options: Flexibility is enhanced due to the offered UV emission tailored to specific applications.

- Thermal Management: These devices can operate continuously while maintaining lower temperatures, making them ideal for long-term use.

- Compact Design: Best suited for portable systems or other tightly constrained environments.

Typical Applications

- UV Curing: UV light for curing adhesives, inks, and protective coatings during electronic assembly, printing, and manufacturing.

- Sterilization & Disinfection: Used for quick chemical-free sterilization of medical and laboratory equipment.

- Photolithography: Uses advanced ultraviolet light (UV) for precision micro-fabrication and semiconductor processes.

- Fluorescence Detection: Enhances visibility for material analysis, biomedical diagnostics, and quality control processes.

- Industrial Inspection: Used for surface or flaw inspection under ultraviolet light in small systems to integrate into miniature systems.

How Do UV LED Modules Function?

A UV LED module consists of multiple ultraviolet LEDs arranged in a chip-on-board configuration on a certain substrate. These modules are used together with UV LED drivers and often paired with precision optics for beam concentration or spreading it to the required width.

Core Components:

• UV LED Chip: It determines the wavelength and power output.

• Driver Circuit: It controls the current and power.

• Optics/Lens: Focuses the light to the required uniform exposure.

• Heat Sink or Cooling System: Maintains thermal stability of the system.

• Mounting Structure: Strength and easy integration into the machine.

Performance Characteristics:

• High-intensity curing up to 20,000mW/cm².

• Low heat emission makes it suitable for sensitive materials.

• Long lifespan ranging from 20,000 to 50,000 hours.

• Energy efficiency consumes 30-50% less energy than mercury lamps.

Industry Specific Solutions

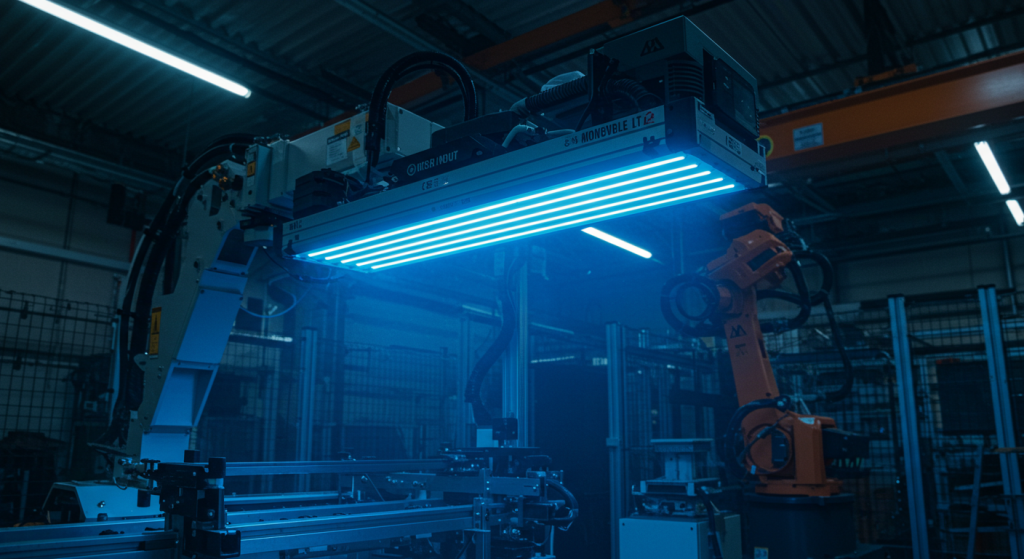

- Electronics Manufacturing

For precision curing of potting compounds, PCB coatings, and encapsulates.

- Printing Industry

- Instant-on and dimmable UV LED systems used for high-speed inkjet, flexo, and screen printing.

- Automotive & Aerospace

- Curing structural adhesives and coatings in automotive interiors, headlamps, and aerospace composites.

- Medical Devices

- Sparse uses a contaminant-free environment and relies on UV LED sterilization for critical tools.

Choosing the Right UV Spectrum

- UV-A (320-400 nm)

• Curing Applications

• Available wavelengths: 365nm, 385nm, 395nm, 405nm

- UV-B (280-320 nm)

• Certain medical and therapy uses.

- UV-C (100-280 nm)

• Used in Sterilization, disinfection, and water treatment.

• Common wavelengths are 265nm, 275nm, and 280nm.

Precision in wavelength selection sharpens effectiveness in material engagement, curing depth, and sterilization accuracy.

Primary Benefits for Industrial Customers

• Improved Productivity: Lower energy use, emissions, and power consumption.

• Tailored Systems: Configured arrays of UV LEDs and optics.

• No warm-up delays: Instant On/Off functionality.

• Compact Form Factor: Space-saving within production lines.

• Eco-Friendly: No mercury is used in UV curing processes.

• Reduced maintenance: Long-life span systems mean infrequent servicing.

Considerations When Selecting an Industrial UV LED Light Module

1. Determine Your Application: Inspection, disinfection, or curing.

2. Select Wavelength: 275nm for sterilization, 365nm for adhesives.

3. Set Power Level: Intensity level should align with task requirements (high or low power).

4. Evaluate Cooling Needs: Small setups are air cooled; intensive setups use water cooling.

5. Confirm Compatibility: Alignment with mounting, control systems, and related optics.

6. Custom Options: Focus loss add-ons or adjustable dimming required?

Developments in Industrial UV LED Technology

• Far UV-C Development: The Unoccupied area is safe for people.

• Smarter Integration: Data collecting IoT-equipped UV modules.

• Higher Efficiency Chips: More UV output per watt.

• Hybrid Systems: Multi-purpose UV-A and UV-C combined.

Industrial Maintenance and Safety

As with any industrial purpose, maintenance and safety for industrial UV LED light module is critical. These modules pose a significant risk of emitting ultraviolet radiation, especially in the UV-C region, requiring careful consideration. To achieve safety and effectiveness, observe these rules:

- Protective Gear:

For all jobs involving UV modules, hand and eye protective gear should be worn. Skin and eye protective gear should be worn as workers could be exposed to harmful UV radiation.

- Ventilation:

Providing good airflow when using UV-C modules in enclosed spaces is crucial. This aids in the removal of ozone and helps prevent overheating of the system.

- Module Care:

Regular lens cleaning maintenance is crucial to ensure consistent light output. Dust build-up can degrade a system’s efficiency. In addition, all cooling systems, whether air or water, must be functioning properly, and heat sinks should be free of dust clogs.

- Lifespan Tracking:

Built-in hour counters and external software can track time, albeit with varying degrees of accuracy. Aging components should be replaced proactively to maintain productivity without needing to dip below optimal output levels.

Conclusion

Beyond being a light source, industrial UV LED light module boost productivity, streamline workflows, minimize waste, and amplify the accuracy of inspections. These modules transform processes, from adhesive curing in aerospace industries to water purification in food processing, with unmatched precision and efficiency. At UVET, we focus on application-specific intensity and high-power UV LED modules tailored for the most demanding industrial environments.