UV LED Module 365nm / 395nm: Key Differences & Applications

What is a UV LED Module 365nm / 395nm?

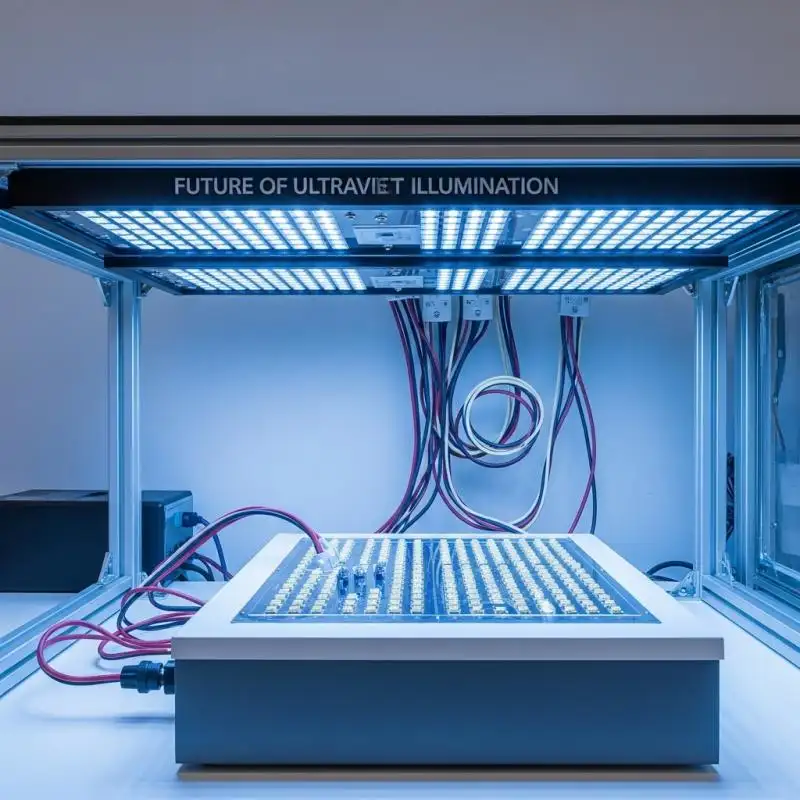

One of the most effective and trusted options for rigorous UV applications is the UV LED module 365nm / 395nm. These modules are used in industrial curing, fluorescence detection, and counterfeit verification. They also deliver dependable and high-output ultraviolet light (UV) in the UVA spectrum. In this article, I will explain the benefits and features of these modules so that you can make an appropriate decision.

Introduction

A UV LED module 365nm / 395nm is a solid-state lighting device. It is classified as an LED module, as it emits subcategory UVA (315–400nm) ultraviolet light (UV). These modules consist of LED chips arranged into arrays and mounted on compact boards with built-in cooling systems.

• 365nm modules are preferred for deep UV fluorescence and high-precision curing.

• 395nm modules are used for fast surface curing and visible fluorescence effects.

These modules also appear to be more efficient and environmentally friendly compared to traditional mercury vapor lamps.

Key Features

Class-Leading Output Intensity:

- These modules enable the rapid curing of paste inks and fluorescence detection processes that require high energy levels. Also, deep UV fluorescence is strongest at 365nm, whereas 395nm is ideal for fast curing of adhesives and resins.

- Excessive thermal management integrated with the modules enhances their life span while also protecting the LEDs from overheating due to integrated thermal substrates.

- Enhanced multifunctionality is exhibited through different handheld and industry-mounted systems offered as modules, bars, and arrays.

- Mercury-free emissions make LEDs eco-friendly, and therefore, their low energy draw, immediate operation, and overall eco-friendliness greatly improve environmental impact.

What are the Applications of 365nm and 395nm UV LED Modules?

Different applications of UV LED modules 365nm / 395nm that need certain benefits have specific requirements.

Specific Benefits of 365 nm UV LED:

• Better fluorescence when photographing and scanning.

• Better penetration when working with thicker plastics, glass, or metals.

• Used for UV curing, forensics, and leak detection in HVAC systems.

Specific Benefits of 395 nm UV LED:

• Provides the best value for money among other products.

• Improved visibility of work due to bluish-purple light.

• Great for nail curing, backlight, and resin curing.

Primary Applications of UV LED 365nm and 395nm

Curing UV Adhesives and Resins:

• Strong bonds are formed in seconds, and curing happens instantly.

• Capable of bonding glass, plastic, and metals.

• Applications in medicine, electronics, and automotive industries.

Curing Coating and UV Ink:

• Curing does not require the use of solvents.

• Achieves uniform surface finish across all materials used.

• Used in the printing, packaging, and signage industries.

Detection of Fluorescence:

• Ability to enhance the visibility of fluorescent substances.

• Used in forensics, biology, and NDT (non-destructive testing).

Preserving Cleanliness and Sanitation:

• Monitoring hygiene practices and compliance can be done through UV light exposure.

• This has the advantage of photocatalytic disinfectants.

• Applicable in the food industry and research labs.

Detection of Counterfeits and Flow:

• Security labels and invisible inks are revealed using ultraviolet light.

• These apply in banking, logistics, and industrial quality control.

• HVAC systems leak testing using fluorescent dyes.

Measurement of UV Output with The Highest Accuracy

Every goal has accessories, and for measuring needs:

1. UV Radiometer – Measures irradiance (mW/cm²)

2. Spectrometer – Checks the cleanliness and the corresponding spectral purity of the emitted wavelengths.

3. Thermal Meter – Controls temperature regulatory measures and thermal control.

Benefits of Having No Contaminants in UV LED

- Compared to mercury UV lamps, these modules have a greatly reduced environmental impact. As industries work towards more sustainable options, UV LEDs are increasingly accepted as safer and cleaner alternatives.

- These modules are free of toxic and harmful emissions since they contain no mercury or ozone. Unlike mercury vapor lamps, these UV LED modules do not endanger the health of operators and end-users and facilitate compliance with environmental regulations such as RoHS and WEEE.

- Furthermore, these modules consume less energy, rendering them more environmentally friendly. They are better for energy-intensive industries because, unlike traditional UV lamps, these modules turn off and on instantly.

- The UV LED’s emission of infrared radiation is so low that there is no need for cooling equipment, which also protects sensitive materials from overheating. An increase in working hours also reduces e-waste. Components have less frequent replacement needs, reducing overall electronic waste.

Modules UV LED: Maintenance and Troubleshooting

System output efficiency is tied to long-term system uptime performance, and precise solid-state systems require accurate maintenance. Targeted maintenance combined with the correct atmosphere guarantees the precise solid-state system optimal conditions. These guiding rules to sustain performance protect modules, improving their longevity:

• Ensure the Upper Limits of Temperatures for Heat Dissipation

Water-cooling or thermal sinks are essential to high UVA modules to avoid overheating due to excess power, and require substantial cooling.

• Protect Internal Parts From Moisture and Dust

Inline optics and other internal components can be protected from harsh environments containing moisture and dust with specially sealed protective enclosures.

• Stable Supplies of DC Voltage

DC voltage supplies must be stable, as unstable or excessive currents will damage LEDs. Constant current drivers specifically designed for UV systems are critical for reliability.

• Routine Maintenance for Optics

UV resin, dust, and fingerprints can be effortlessly removed using lint-free alcohol swabs.

UVET – Products of High Performance

- Specialization in the high precision industrial grade UV LED modules places focus on the multifunctional uses, ranging from curing, inspection, and detection. Tailored to high-fidelity UV adhesive curing, ink drying, counterfeit detection, and fluorescence inspection, our precision modules emit radiation at 365nm and 395nm.

- Clients from the electronics and printing industries, as well as forensics, can rely on the constant optical output and high optical efficiency of UVET modules.

Why is UVET Your Preferred Partner?

- Industry Leadership

We gain an advantage by serving industrial and commercial clients, which stems from more than 10 years of concentrated UV LED research, development, and production work. This advantage is received after serving industrial and commercial clients.

- Custom-designed options for UV Modules

Parameters such as radiant power, cooling type (air or water), lens optics, and even form factor can be specified along with the wavelength.

- Certified Quality

Our company operates with CE, RoHS, and ISO certifications. We maintain environmental and safety compliance during our production processes. Furthermore, each unit manufactured is fully certified for international distribution.

- End-to-End Technical Support

We offer assistance to our clients from onboarding through design delivery, integration, and continue to offer post-sales support.

- Scalable Production

We support custom prototypes and bulk order requests from both emerging startups and established multinational corporations.

Conclusion

The UV LED modules 365nm and 395nm offer high reliability and strong optical output, making them ideal for FL detection and industrial curing applications. All specification figures are to be interpreted; proper selection of wavelength is critical alongside robust system design for long-term operation. If you are still looking for a perfect fit, get in touch with us. We would be more than happy to assist you in selecting the best module. Visit UVET.