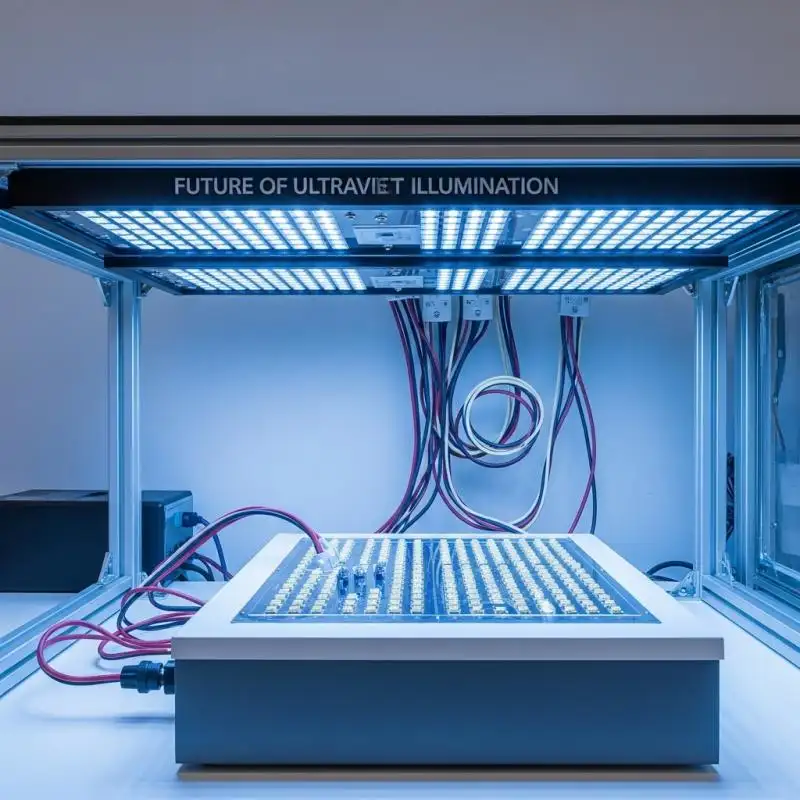

What is UV LED PCB Module? Power, Performance & Applications

What is a UV LED PCB Module?

A UV LED PCB module is a dedicated device that combines ultraviolet light-emitting diodes (UV LEDs) and a printed Circuit Board (PCB). This combination gives accurate control over the UV wavelengths, easy heat dissipation, and dependable service over a wide range of applications. The UV PCB module is a handy technology when it comes to high-performance curing, sterilization, and exposure systems. Whether it is industrial curing or water purification, these small but mighty devices are shaping industries. This guide will take a closer look at all the things you need to know about UV PCB modules, their structure, technical characteristics, application, and what makes them better than traditional UV light sources.

UV LED modules are applied in:

• UV curing (resins, adhesives, inks)

• Sterilization and disinfection (air, water, surfaces)

• Photo lithography and PCB exposure

• Analysis and medical instruments

In contrast to the conventional mercury lamp, UV LED modules are energy-saving, environment-friendly, and have a high working life.

UV LED PCB Modules' Major Constituents

Now, let us get into the technical aspect. A standard UV LED PCB module consists of:

1. UV LEDs (UVA, UVB or UVC)

2. Heat management PCB: Aluminum or Metal Core PCB (MCPCB)

3. LED Driver constant current regulation.

4. Thermal interface material

5. Optical lens or diffuser

6. Protective coating and encapsulation

The industrial modules are mostly available with 365nm, 395nm, or 405nm LED, depending on the needed application. To sterilize, 275nm or 265nm UVC LEDs are common.

UV LED PCB Modules Types

1. UVA LED PCB (365nm / 395nm / 405nm)

Very suitable for curing, 3D printing, and coatings.

2. UVB LED PCB

Application in dermatology and special sterilization systems.

3. UVC LED PCB (265nm 275nm)

Intended use in germicidal UV applications (e.g., water and air disinfection).

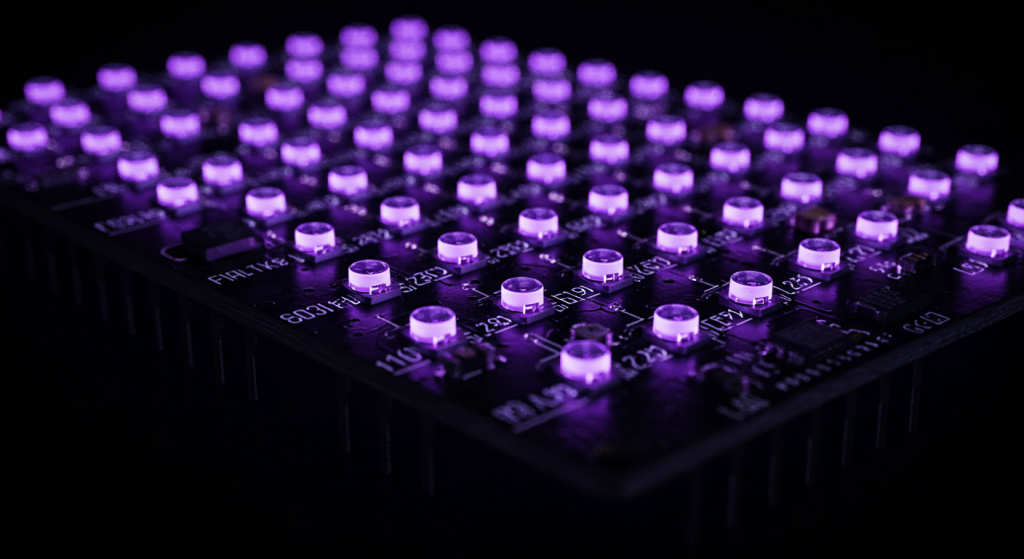

4. PCB SMD UV LED

Surface mount LEDs can be used to provide high-density, small-sized light arrays.

5. UV LED Module COB

Higher light intensity and uniform output are made possible through chip-on-board technology.

6. Flex and Rigid PCB Modules

Adjustable to suit different industrial and medical equipment.

Technical Specifications to Be Taken into Consideration

When selecting a UV LED PCB module, the following important specs should be taken into consideration:

• Wavelength (e.g., 365nm curing, 275nm disinfection)

• Power Output (e.g., 3W to 100W+, App dependence)

• Thermal Resistance

• Light Flux and Intensity

• Beam Angle

• Driver Compatibility

• Temperature Range of Operation

The high-performance modules mostly come with heat sinks attached and must have adequate thermal management to enhance durability.

Industrial and Scientific Applications

UV LED modules are applicable to many industries:

• Electronics Manufacturing: To expose PCBs and cure solder masks.

• Medical Devices: Within sterilization chambers and UV analytical systems.

• Water and Air Sterilization: By UVC sterilization modules.

• 3D Printing: To cure resin and make prototypes.

• Adhesive and Coating Curing: Rapid curing, clean curing, industrial lines.

• Photolithography: To pattern high-precision circuit boards.

Benefits of UV LED PCB Modules

Mercury-Free: Safer and Pro-environment: Safer and friendlier to the environment.

UV LED modules do not include mercury, unlike conventional UV lamps. These are safer for the user and for the environment, which is in line with the current green manufacturing trends.

- Energy Efficient: Less Power Consumption

These modules use much less electricity as compared to mercury vapor lamps, which are beneficial in reducing operating cost, alongside the fact that they have high output efficiency.

- Space-Saving Design

UV LED modules are available in a small form factor, making them suitable to be use in compact and portable equipment, ideal in high-tech and space-constrained applications.

- Instant On/Off: No Warm-Up Required

When they are turned on, they provide instant UV output; there is no waiting and no flickering. This offers them applicability in time-critical industrial and medical applications.

- Adjustable: Several Set-up Options

The wavelength (265 nm- 405 nm) can be selected, the PCB layout can be flexible, and these modules can be customized to a particular curing or disinfection application.

- Long Lifetime: 10,000- 50,000 Hours

Compared with the traditional ones, UV LED modules have a much longer service life, which minimizes maintenance downtime and replacement expenses.

- Accuracy Control: tight Wavelength Output

You have pinpoint wavelength delivery to target certain processes- important in curing, photolithography, and sterilization applications.

How to Select the Appropriate UV LED PCB Module?

The important considerations include:

1. Determine Your Application: Curing, disinfection, exposure, or analysis application?

2. Wavelength Requirements: Select between 265nm and 405nm depending on the target.

3. Power Requirements: Again, a couple of module outputs to curing or disinfection requirements.

4. Form Factor: St rigid or Flexible? SMD because of COB?

5. Thermal Management: Make sure that your design has an appropriate heat sink.

6. Driver Compatibility: LED drivers should be used to ensure stability.

Require a tailor-made solution? Have a look at our UV LED module design custom service.

Maintenance/Safety

UV light may be damaging to the eyes and skin. Always:

• Wear protective eyewear

• Do not get it directly exposed

• Shielding designs

Maintenance includes:

• Periodic cleaning of optical surfaces.

• Thermal paste intactness

• Supervision of driver performance

Purchase UV LED PCB Modules

Seeking quality, high-performance modules? To view a complete selection of industrial UV LED products, go to the UVNDT product catalog.

We offer:

• Tailor-made module development

• Application engineering assistance

• Speed of prototyping and delivery

In addition, utilize external perspectives such as market trends of UV LED by LED inside to keep abreast of technological advancements.

Conclusion

Whether it is adhesive curing or water sterilization, UV LED modules are defining the future of industrial, medical, and scientific usage. They are small, adjustable, compact, and more efficient than the mercury-based systems in every aspect. With the appropriate UV LED PCB module selected to suit your specifications, the excellence of performance, enhanced lifespan, and risk-free operation will be opened to you. Contact the team of UVET to get detailed assistance and individual solutions.