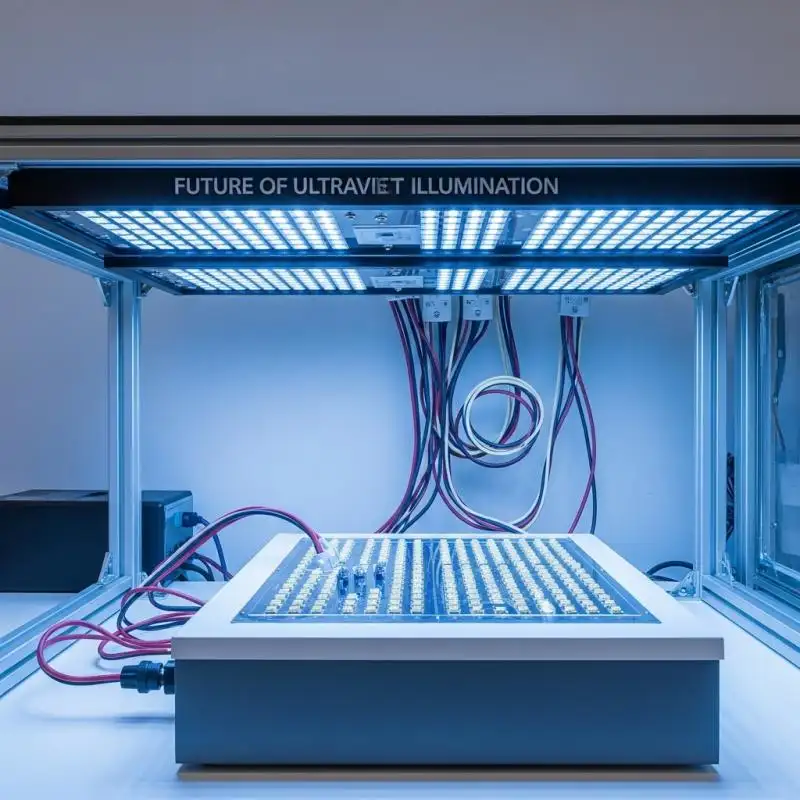

Water-Cooled UV LED Module for Long-Lasting Performance

What is a Water-Cooled UV LED Module?

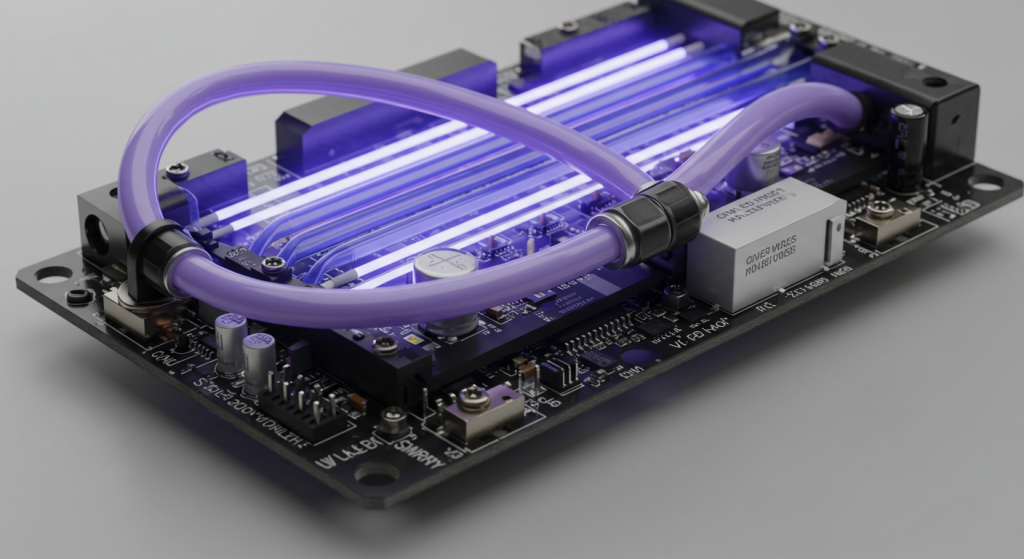

A water-cooled UV LED module includes high-power UV LEDs and other modules whose heat is eliminated through liquid flow. These modules outperform air-cooled equipment, which is less effective due to introducing a lot of variability which resulting in temperature inconsistency. Water-cooled systems outperform air-cooled counterparts owing to providing more stable temperature control, resulting in enhanced durability, improved efficiency, and more consistent steady UV output.

Some common applications include:

• Adhesives, inks, and coatings curing.

• UV sterilization in medical and other industrial fields.

• Manufacturing of electronics.

• Production in the automotive industry.

Key Technical Features

• Type of Cooling: Circulatory cooling using water jackets or water chillers.

• Supported Wavelengths: Common UV-A (365nm, 385nm, 395nm, 405nm) and UV-B and UV-C (265-280nm).

• Range of Power: 4W/cm² to over 20W/cm².

• Thermal resistance: Low, which aids in controlling UV exposure precision.

• Shape: Often compact, modular, and easy to integrate into other systems.

Why Cooling Matters for High-Power UV LED Modules?

Managing heat is one of the most significant problems with high-power UV LED systems. If not cooled properly, LEDs will experience:

• Overheating.

• Decrease in UV output.

• Thermal runaway.

• Decreased life span.

Water-cooling systems are highly effective. With circulating water UV LED cooling, excess heat is removed from the LED junctions, resulting in:

• Constant light output.

• Improved operational lifetime.

• Consistent long-term curing performance.

Why Choose Us?

- One of the top producers of UV LED curing systems and a reliable supplier of printing application solutions is UVET. With a skilled staff in research and development, sales, and post-purchase support, we guarantee that our products fulfill global dependability and safety standards.

- Being a customer-focused business, we genuinely think that establishing enduring bonds based on mutual success and trust is important. In addition to offering top-notch UV LED solutions, we also want to help our clients along the way.

- UVET is available to help our clients with anything from initial consultation and installation to maintenance and troubleshooting.

Use Cases of Water-Cooled UV LED Modules

1. UV Curing Systems

UV inks, coatings, and adhesives are cured in:

● Flexible Package Design

● Circuit Board Assembly

● Furniture Manufacturing

2. UV Printing

Maintaining precision in plastic UV inkjet printers requires consistent operation throughout the process. Water-cooled LED modules resolve overheating problems while also maintaining the required temperatures for proper ink adhesion during printing.

3. 3D Printing (Resin Based)

3D printing with resins is well known for its use of compact light sources that generate very little heat. Smoother prints are achieved when multiple layers are cured quickly, and the strength and temperature are consistent during the curing phase.

4. Medical Sterilization and Disinfection

UV-C systems with low output for surgical, clinical, and laboratory purposes have a lower heat risk. These modules are associated with greater surgical efficiency.

Benefits of Water-Cooled UV LED Modules

- Greater Efficiency

Water cooling is effective in systems with deep curing acceleration, as well as those using ice-water-cutting techniques, which are highly thermally absorbent.

- Reduced Operating Temperature

This is important for thin films and for delicate medical tools and devices.

- Uniform Output of UV Radiation

Your system avoids runaway overheating and achieves consistent thermal equilibrium and steady thermal equilibrium. This improves consistency in curing, product reliability, quality, increased dependability during prolonged operation, and system dependability.

- Maximum Service Life

ROI improves due to lower supply, LED, and replacement costs because of reduced thermal stress.

- Compact Structure

Streamlined thermal management and vertical stacking lead to more compact structures, eliminating space on the production line.

Primary Considerations When Choosing a Module

From the point of view of design, the aims of a given application will shape its features and requirements.

1. Selecting Wavelengths

Not every ultraviolet wavelength is applicable. Options include 365 nm, 385 nm, 395 nm, and 405 nm (UV-A). UV-C (265-280 nm) is reserved for sterilization purposes.

2. Power Density Requirements

For faster systems, uniform irradiance over the entire targeted area is necessary, as well as a 15W/cm squared minimum power density.

3. Cooling Flow and Thermal Conductivity

Water flow rate and thermal conductivity both affect the system’s efficacy. For optimal heat transfer, thermal resistance should be less than 1.5 degrees Celsius per watt, alongside a water flow rate between 1 to 2 liters per minute.

4. LED Arrays Optimization

Select linear or matrix arrays based on shape and area coverage. Optimal spacing between elements is critical to achieving uniform UV exposure.

5. Compatibility of System Control Functions

PWM or analog dimming automation with a defined minimum resolution can be checked for system specification compliance.

Use Cases By Industry Section

- Electronics Manufacturing

Due to uniform exposure, a high-power water-cooled UV LED head is perfect for the curing of PCB conformal coatings, as it does not overheat sensitive chips.

- Automotive Assembly

Used for curing plastic parts, headlamp sealing, and optical bonding. For these applications, modules are essential due to the need for precise UV output control and stable operation to prevent defects during these critical and sensitive processes.

- Medical Devices

Cleanroom modules must operate completely silently, with minimal thermal output, and provide maximum reliability. Units can be cooled and sterilized during cool down by chilled arrays emitting UV at 265 nm- 280 nm, making them safe for cooled and sterilized devices.

Benefits of Water-Cooled Modules

LED Modules offer the following benefits over conventional mercury UV lamps:

• No mercury content

• Increased efficiency

• Always On Standby

• Extended Viability

Choosing a Module That Best Fits Your Application

To help assist you with the selection of the module, here are five critical criteria:

1. Curing Area and Materials to Be Processed

2. Required UV Intensity

3. Required Wavelengths of Ultraviolet Radiation—UV-A, UV-B, or UV-C

4. Heat Sensitivity

5. Need for Modular and Scalable Systems

Conclusion

Are you looking for trustworthy, comprehensive suppliers of UV and LED devices? Take a look at other modules offered by UVNDT that combine sophisticated water-cooling systems. Alongside, taught creativity reinforcement, unmatched engineering eco-friendly frameworks, and ultraviolet galvanic systems make flexible UV LED technologies non-competitively priced. For further information, visit UVET.