What are UV LED Modules? The 2025 Guide to UV Light Technology

What is a UV LED Module?

What are UV LED modules? A UV LED module is a small device that generates ultraviolet (UV) light using solid-state UV light-emitting diodes (LEDs). Compared to traditional UV lamps that use mercury vapor or gas discharge, UV LED modules are more efficient because they utilize semiconductor chips to generate UV light of particular wavelengths. These modules are cost-effective, environmentally friendly, and have a long lifespan.

How Do UV LED Modules Work?

- Each UV LED module contains a UV LED chip, which is a type of semiconductor that emits UV light when provided with electric power. These chips are mounted onto arrays and connected to UV LED drivers that control the power supply. As with other semiconductors, the design of the module includes provisions for heat management to remove excess heat and improve its efficiency.

- The solid-state design of the units enables them to instantly turn on and off, in contrast to mercury lamps, which require warm-up time. The precision control offered by UV LEDs over output power and wavelength makes them easy to control in use.

How to Select the Right UV LED Module?

Selecting the right UV LED module is important in achieving optimal output for your application. Different applications, like curing adhesives or disinfection, have varying requirements. Here’s a simple guide designed to help you pick the right UV LED module according to your specific requirements.

1. Selecting the Purpose of the Module’s Application

Like with other devices, the UV LED module has its primary application. It can be used for different purposes, like:

• Curing for drugs, adhesives, inks, and coatings.

• Disinfection and sterilization of water, air, medical instruments, and other equipment.

• Excitation of fluorescence for diagnostics and lab sensors or non-destructive testing (NDT).

• Utilization in printing or therapy using radiation in the ultraviolet range.

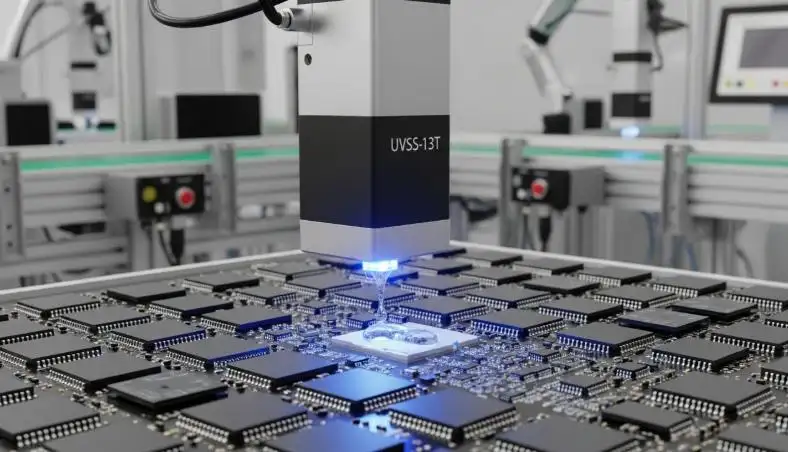

• Industrial visual inspection systems

2. Confirming Output Power and Intensity

Output power will determine the speed and efficiency of your UV LED module. It is measured in:

• MW/cm² (milliwatts per square centimeter) and

• Total radiant flux in mill watts (mW) or watts (W)

Stronger output translates to quicker curing or stronger fluorescence signals. Also, decide on the beam type:

• Spot modules for focused beams

• Flood modules for wide area coverage

• Linear modules for conveyor systems or line scanning

3. Evaluating Thermal Management Systems

UV LEDs create significant heat that needs to be managed to prevent performance drops or shorten the lifespan of the LEDs. Look for:

• Integrated fans or water-cooled modules

• Low thermal resistance materials like aluminum MCPCB or ceramic bases

Without effective heat dissipation, overheating occurs, and efficiency increases the likelihood of module failure.

4. Checking Power Supply and Drivers Compatibility

Make sure to check your power requirements:

• Common voltages include 12V or 24V

• Modules might need constant current or constant voltage drivers

• Some UV LED modules come with integrated drivers; others require external drivers.

5. Configuration and Installation

Take into account the physical fit:

• The shape of the module can be round, strip, or square

• Installation can be plug-and-play or PCB mounted

• For humid, dusty, or outdoor environments, check the IP rating

Wavelength and Applications of UV LED Modules

With different wavelengths, UV LED modules have a specific use for each. Wavelengths between 265 to 280 nm (UV-C) are very effective for sterilization, disinfection, and germicidal processes, so they are best suited for water purification and surface disinfection. The 300 to 320 nm (UV-B) is utilized in phototherapy and other biochemical uses because it is capable of interacting with living tissues. The 365 nm (UV-A) is widely used for UV curing as well as fluorescence and inspection tasks. Finally, for general lighting and curing applications, 395 to 405 nm modules are a cheap alternative offering a good price-to-performance ratio.

Applications of UV LED Modules

The most significant applications of UV LED Technologies span across diverse industries, which makes it an exceptionally important and adaptive technology. The most notable ones include:

1. Disinfection and Sterilization with UV LEDs

The applications of UV LEDs in surface disinfection are one of the most rapidly expanding fields. Medical-grade surfaces can be disinfected using UVC LEDs as they eliminate the microbial DNA and RNA, rendering them incapable of replicating. As such, these LEDs are critical for surface disinfection, surgical instrument sterilization, and preservation of food items.

2. Curing of Ink, Resins, and Adhesives

The modules that emit UVA LEDs are utilized for the curing of materials since they accomplish this task faster and more effectively than their predecessors. This has led to immense gains in the printing, automotive, and electronic manufacturing industries.

3. Purification of Water and Air

Similar to the aforementioned technologies, UV LED modules for water purification are used to disinfect drinking water by eliminating hazardous microorganisms without the use of chemicals. Moreover, UV LEDs designed for air sterilization are installed in air purifiers and HVAC systems to improve indoor air quality.

4. Medical Uses

Wound healing and dermatology are a couple of medical uses of UV LEDs alongside phototherapy for skin conditions. In particular, UVB LEDs are helpful in treatments.

5. Widespread Industrial Use

The use of phytoremediation along with UV LEDs aids in the detection of counterfeit items, which helps in keeping the products genuine and the environment safe.

Advantages of UV LED Modules

What are UV LED modules, and why is there a preference for UV LED modules over UV lamps? It is because this uses UV LED modules with numerous advantages:

- Energy Saving UV LED Technology

Comparing power consumption, UV LED modules yield profit in comparison to mercury lamps. Operational cost and nature-friendly impact on the environment are reduced due to the energy-efficient design operational system.

- Long Life UV LED and Dependability

Maintenance is minimal when it comes to UV LEDs. The lifespan is often over 10,000 hours, which makes it more dependable and persistent.

- Mercury-Free and Eco-Friendly

As compared to traditional mercury vapor lamps, UV LEDs are safer and comply with regulations of environmental laws.

- Compact Shape and Flexible Design

Application potential is increased because their compact shapes and small sizes fit into small and complex equipment.

Main Features of UV LED Modules

To understand performance, consider these key components and specifications:

- UV LED Chips and Arrays

To enhance the output power, high-grade UV LED chips are arranged into arrays. These arrays provide a consistent distribution of UV light.

- Wavelength and Output Power

A module’s specific tasks are best served by its UV LED wavelength, while its effectiveness is determined by UV LED output power.

- UV LED Efficiency and Cooling

To maintain UV LED performance and prolong its lifetime, efficient thermal management systems must be in place to prevent overheating.

- UV LED Drivers

Maintained overall performance hinges on effective management of voltage and current, which is controlled by the UV LED drivers.

Conclusion

What are UV LED modules? These devices are semiconductor chip-based ultraviolet emitters that are innovative, efficient, and environmentally friendly. They are tailored for specific applications like UV LED disinfection, medical phototherapy, and industrial curing, which necessitate diverse module types configured to different wavelengths. For expert advice and cutting-edge products, visit UVET to see how their UV LED modules can transform your business operations.