What are UV LED Modules Used for? Unlock the Power of UV LED

Applications of UV LED Modules

- UV LED modules are becoming essential in different fields such as electronics, medicine, printing, production, and manufacturing because of their precision, flexibility, and effectiveness. They are important in the curing of adhesives, inks, and coatings for photoresist materials for fast, clean, and effective curing. Furthermore, their spatial accuracy and controlled wavelength emissions of 365nm, 385nm, 395nm, and 405nm make them invaluable in photolithography for semiconductor and microfabrication processes.

- UV LED modules are important for disinfecting and sterilizing areas of labs and hospitals. They offer effective microbial control without the use of chemical agents within the UV-C range. These modules also assist in fluorescence-based detection systems used in diagnostics and quality evaluation in biological research.

Most Important Advantages of COB UV LED Modules

- Increased High Power Density

The modules use focused UV radiation to enhance speed when curing and sterilization processes within small areas, thus increasing power density.

- Improved Thermal Performance

Directly mounting LED chips on aluminum or ceramics enhances heat loss and improves thermal performance. This, in turn, helps the longevity and dependable functioning of a module.

- Illumination Consistency

For effective curing and inspection, the consistency of UV distribution is critical. Therefore, the elimination of hotspots and uniform exposure is essential.

- Customizable Geometries

Modules are offered in round, square, and rectangular shapes to fit a system's requirements as well as the design of the installation.

- Energy Efficient and Instant-On

The performance, including energy consumption and activation time, using low power and instantaneous activation, is both cost-effective and environmentally friendly.

What are UV LED Modules Used For?

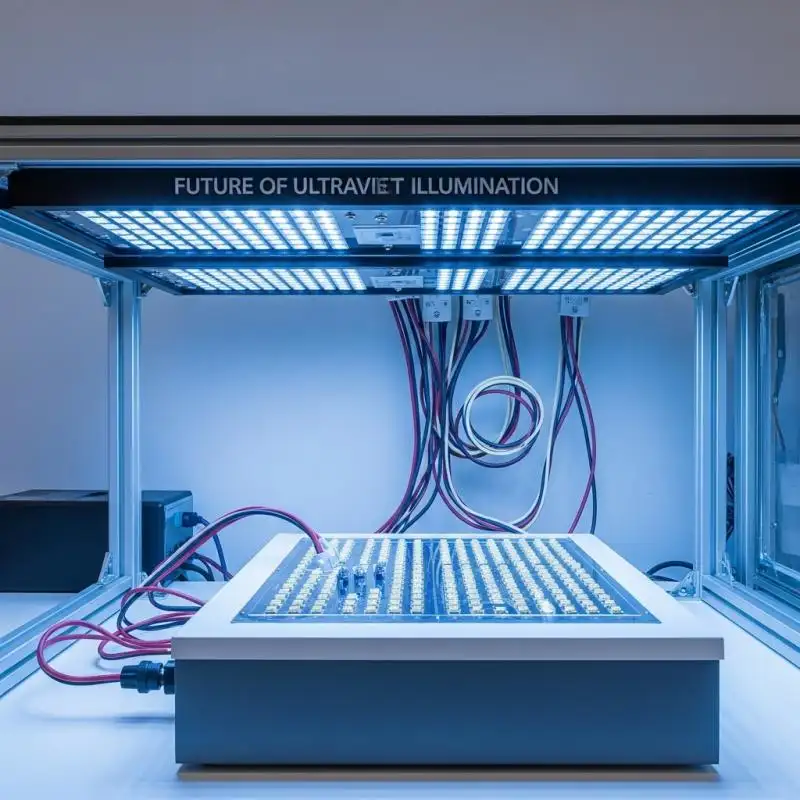

What are UV LED modules used for? UV LED modules are designed as modern light sources for specific industrial and scientific processes that use ultraviolet radiation. They serve demanding applications because of the reliance on precision optics and multi-LED arrays ensure in providing uniform output and stable wavelength performance throughout the processes.

- Array LED UV modules boast a grid arrangement of high-powered UV LEDs, which allows the generation of broad and intense fields of ultraviolet radiation. Due to consistent coverage and speed, these modules are used widely for large-area exposure industrial curing, printing, and coating. Additional applications include sterilization, disinfection, and semiconductor processing.

- These modules are capable of emitting a range of wavelengths at 365nm, 385nm, 395nm, and 405nm. They are flexible and can be customized for size, power, and integration requirements with automated systems and production lines.

Typical Applications of UV LED Modules

- High-Speed UV Curing

This is used during the quick curing of UV-sensitive inks, adhesives, and coatings, particularly in the electronics and packaging industries.

- PCB Exposure & Drying

For imaging and post-processing work on printed circuit boards, the uniform distribution of UV light during exposure and drying is very critical.

- Photolithography & Semiconductor Manufacturing

Patterning precision is preserved with shallow and deep UV lithography techniques.

- Medical Sterilization

Cleaning surfaces such as tools, gear, and sterile rooms.

- Advanced Printing Systems

Used for Flexo, screen, and inkjet printing, offers UV light for quick-drying and durable finishing inks.

Environmental and Health Benefits

Regarding health and environmental concerns, the use of UV LED modules has several advantages, as listed below:

• No Mercury: Due to the absence of mercury in UV LED modules, they are more beneficial to the environment when compared to traditional mercury UV lamps.

• Minimal Heat Output: Lower chance of overheating fragile materials.

• Reduced Power Usage: Reduced power consumption also means reduced greenhouse gas emissions.

Technical Specifications and Considerations

When selecting modules of UV LEDs, the following technical specs must be considered:

• Wavelength: Select the appropriate range (UVA, UVB, and UVC).

• Power Output: More power means more intense and effective industrial-grade UV light.

• Beam Angle: Narrow angles give focused illumination while wider angles cover more area.

The right UV LED module can be configured by knowing the specifications and requirements of the application.

Market Trends and Future Outlook

The UV LED market is expanding rapidly because of emerging technologies and increased usage in various industries.

- Healthcare: The use of UV-C LEDs is growing for disinfecting and sterilizing procedures.

- Manufacturing: Greater use of UV LEDs in curing has improved speeds in manufacturing processes.

- Consumer Electronics: Use of UV LEDs in devices for purifying air and surfaces.

As the focus on UV LED modules improves, there will be new advancements in technology that adapt to changing demands.

Buy UV LED Modules – Durable, Energy-Efficient & Powerful

Your Trusted Partner in UV LED Technology

- With years of experience in the market, UVET has become one of the leading manufacturers of UV LED curing systems and a trusted provider of integrated solutions in printing and industrial automation. UVET serves many industries as it focuses on innovation, quality, customer satisfaction, and dependability. These industries depend on precise UV light for curing, sterilizing, and processing.

- Reliability, energy consumption, and operational efficiency are the primary considerations in the design of UV LED modules. Tailored for curing, coating, and photolithography processes, our modules also support essential wavelengths of 365nm, 385nm, 395nm, and 405nm. Moreover, they come in various arrays and COB form factors. Whether you are integrating one into a new production line or enhancing a pre-existing device, UVET offers compact, industrial, and scalable solutions tailored to your needs.

Dependability and Innovation

Every product UVET develops goes through rigorous scrutiny for performance, safety, and dependability through a multi-disciplinary team focused on R&D, application engineering, and quality control. Because our modules are internationally recognized, manufacturers and research institutions trust their stable performance, uniform UV output, and low maintenance needs.

Customer-First Commitment

At UVET, sustaining client relationships is our priority. From preliminary consultations to post-installation, we provide technical guidance, customization, and other services. Our enduring partnerships stem from this belief, proving that we are customer-first beyond just philosophy.

Conclusion

What are UV LED modules used for? In this modern era, UV LED modules are vital components and are integrated into a wide range of devices. They are useful in several industries because of their effectiveness, eco-friendliness, and versatility. With the pace of technological advancements in recent times, UV LEDs are likely to have even more applications in the future, enabling them to address more challenges. For more information on the applications and benefits of UV LED modules, please visit UVET.