What's the Difference Between UV LED Modules and Traditional Lamps?

What are UV LED Modules?

Technology incorporating ultraviolet (UV) light has transformed numerous industries, ranging from medical to disinfection, to manufacturing and curing. One of the most important breakthroughs in UV technology is UV LED modules, which have distinct advantages over traditional UV lamps. This article discusses the most important features of UV LED modules and traditional lamps: their performance, efficiency, lifespan, environmental impact, and applications, and what is the difference between UV LED modules and traditional lamps?

Clarifying Differences Between UV LED Modules and Traditional UV Lamps

• UV LED Modules

UV LED modules are solid-state devices that generate ultraviolet light radiation as a result of electric current flowing through them. They are compact and energy efficient, able to emit specific bands of ultraviolet light, for instance, UVC, which is widely used for disinfection.

• Traditional UV Lamps

Thermal-activated lamps, such as mercury vapor, low-pressure, and medium-pressure ultraviolet lamps, encompass a wide range of UV light sources. These lamps are based on mercury vapor excitation to emit UV light; however, they suffer from several drawbacks high energy consumption and environmental disadvantages.

Performance Comparison

- Wavelength Specificity

The emission wavelengths of UV LED modules, such as 254nm, 265nm, and 275nm, are particularly suited for germicidal applications. In comparison, conventional UV lamps tend to emit a wider array of UV light, which is not as useful for specific applications.

- Instant On/Off Capability

UV LED modules enable instantaneous functionality, both on and off, with no warm-up time required. Conversely, traditional UV lamps need a warm-up period to function at peak efficiency.

- Curing Speed

UV LED modules are beneficial to applications like printing and nail polish curing as they offer higher intensity and emit specific wavelengths, leading to faster curing speeds. Slower curing times in traditional UV lamps are accompanied by less precise control over emitted wavelengths.

Efficiency and Energy Consumption

- Wall-Plug Efficiency

UV LED modules demonstrate high wall-plug efficiency, where a large fraction of electrical energy is converted to UV light. Traditional UV lamps often operate at a lower efficiency, consuming more energy in the process.

- Power Density

UV LED Modules exhibit high power density and thus intense compact UV output. Traditional UV lamps are often bulky as they require more space to achieve comparable power densities.

Lifespan and Maintenance

• Lamp Life

UV LED modules have a longer lifespan than traditional UV lamps. Unlike traditional lamps, which require frequent replacements, UV LEDs can be used for thousands of hours before needing to be replaced.

• Maintenance Requirements

UV LED modules have low maintenance compared to traditional lamps because of their long-lasting, durable design. Components such as traditional UV lamps need regular maintenance and eventual replacement.

Environmental and Safety Considerations

• Mercury-Free Operation

UV LED Modules are free from mercury, which makes them less dangerous for the environment when it comes to mercury’s hazardous disposal. Products such as mercury vapor lamps are traditional UV lamps that carry mercury, creating risks for the environment and people’s health.

• Ozone Generation

Compared to traditional UV lamps, UV LED modules produce less ozone, making them less dangerous for indoor use. The traditional UV lamps still have the danger of producing ozone, which is harmful in closed places.

Heat Emission

Less heat is emitted from UV LED modules, which improves the operating environment and decreases the need for cooling systems. Traditional UV lamps pose a danger through excessive heat, which demands effective management solutions for temperature control.

Design and Application Flexibility

• Compact Size

Flexibility for different systems and applications is enabled by the lightweight and compact design of UV LED modules. Conversely, traditional UV lamps are bulkier and require more space for installation.

• Applications

UV LED modules have a wide range of applications, including disinfection, water purification, air purification, nail salons, and printing, as well as in the medical field for sterilization and curing. Similar to UV LED modules, traditional UV lamps fulfill these functions; however, they are generally more costly and cumbersome to maintain.

Cost Analysis

• Initial Investment

Compared with traditional UV lamps, UV LED modules are more expensive. That said, traditional UV lamps have a higher operational cost compared with UV LED modules, which can help recover the upfront cost of UV LED modules over time.

• Operational Costs

Complementing the trends set by traditional UV lamps and UV LED modules, UV LED modules operate more efficiently because they use less energy and require minimal maintenance.

Applications: Where the Differences Matter Most

The unique features of both UV LED modules and traditional lamps mean they excel in different applications and will continue to do so for the foreseeable future.

- Disinfection & Sterilization:

The effectiveness of UV LED disinfection is reaching new levels. The UVC LED germicidal lamps are transforming healthcare surface disinfection as well as water (point-of-use systems, municipal treatment), air (HVAC systems, air purifiers), and even air purification. The incorporation of compact, mercury-free UV LEDs that can be integrated directly into products makes these devices very versatile.

Despite the advantages offered by UV LEDs, traditional germicidal low-pressure mercury lamps are still dominant in large-scale air and water treatment facilities. However, UV LED use is growing due to their efficiency and environmental advantages.

- UV Curing:

The comparison between UV LED curing and more traditional approaches is gaining traction. In printing, flexo, inkjet, and even 3D printing, Photopolymerization is increasingly adopted because of UV LEDs. Tailored material properties can be achieved because exact wavelength control reduces shrinkage and improves toughness during curing. Energy wastage from idle times is greatly reduced because of the instant on/off feature. Faster curing times with UV lamps for nails are made possible without the heat problems from older UV lamps.

Some high-power industrial curing applications continue to use traditional medium-pressure lamps, but UV LEDs are continuously adapting to these needs.

- Medical Applications:

The use of UV LEDs in medical devices for sterilization, diagnostics, and even phototherapy is growing. Here, their size and accuracy are particularly helpful.

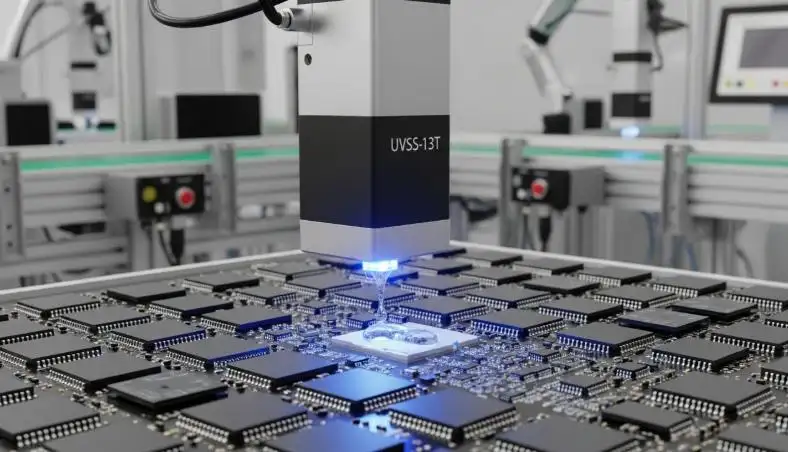

- Industrial UV LED Solutions:

The capabilities of UV LED modules are providing new opportunities within the industry, from sensor technologies to specialized industrial applications requiring unique levels of precision and control.

The Future of UV Light Technology: A Clear Horizon

The direction of development is apparent. Where the technology for UV light will be applied in the future is undoubtedly in the UV LED modules. With ongoing research and development efforts, we anticipate:

• Further increases in effectiveness and decreases in energy consumption.

• Increased output of UV radiation and power density, which will widen the scope of their use further.

• Decreased cost of production, thus a lower price.

• Introduction of new niche applications at new UV wavelengths.

The superiority of UV LED modules over traditional UV lamps is overwhelming. They address critical environmental concerns and offer superior performance and long-term economic value. While there will always be some applications where traditional lamps will be used for some time within specific legacy systems, the steady movement is toward solid-state UV lighting.

Why Pick UV LED?

For both companies and individuals, the answer to the question, “Why select UV LEDs instead of standard UV options?” is becoming increasingly clear:

• Innovation: Adopt mercury-free UV sterilization and become part of the solution.

• Cost Efficiency: Experience operational savings, lower energy bills, and cut maintenance costs.

• Improved Functionality: Provides a wide array of system dependability, speed in curing, disinfection precision, and reliability.

• Agility: Sustains ongoing progress, making investments in it extremely valuable.

Conclusion

What is the difference between UV LED modules and traditional lamps? Overall, the upfront difference of UV LED technology could be perceived as its performance, efficiency, longevity, environmental adherence, and adaptability far outweighing traditional UV lamps. As UV light technology progresses, we can anticipate UV LED modules to become increasingly integral across all industries. For more information, visit the UVET website.