Air-Cooled UV LED Curing Light: When It’s Enough

In the design of an efficient production line, selecting the appropriate thermal management for your ultraviolet sources is as important as the light itself. While many high-intensity applications gravitate toward liquid cooling, the air-cooled UV LED curing light remains a highly effective and popular choice for many industrial configurations.

This guide examines the technical conditions where air cooling provides sufficient performance, the impact of airflow on output stability, and how to evaluate if this self-contained cooling strategy fits your process. By understanding the thermal limits of air-cooled systems, you can simplify your equipment integration and reduce overall system complexity.

What Is an Air-Cooled UV LED Curing Light?

An air-cooled UV LED curing light relies on moving air to remove heat from the LED modules and deliver UV energy for curing without water circulation. You will notice that these systems typically utilize integrated fans or high-surface-area heat sinks to pull thermal energy away from the semiconductor chips. Because they do not require external chillers or plumbing, air-cooled units are often more compact and easier to integrate into existing machinery. This design is focused on portability and simplicity, providing a "plug-and-play" solution for many industrial curing tasks.

Why Is Cooling Important for UV LED Curing?

Cooling is important for UV LED curing because excess heat can reduce output stability, alter intensity distribution, and shorten component life if not adequately managed. You will find that LEDs are temperature-sensitive devices; as the internal junction temperature rises, the efficiency of light production drops. This thermal decay can lead to a noticeable drop in irradiance over the course of a production shift if the cooling system cannot keep up. Maintaining a stable operating temperature is the only way to ensure that the ultraviolet dose remains consistent from the first part to the last.

When Is Air Cooling Enough for UV LED Curing?

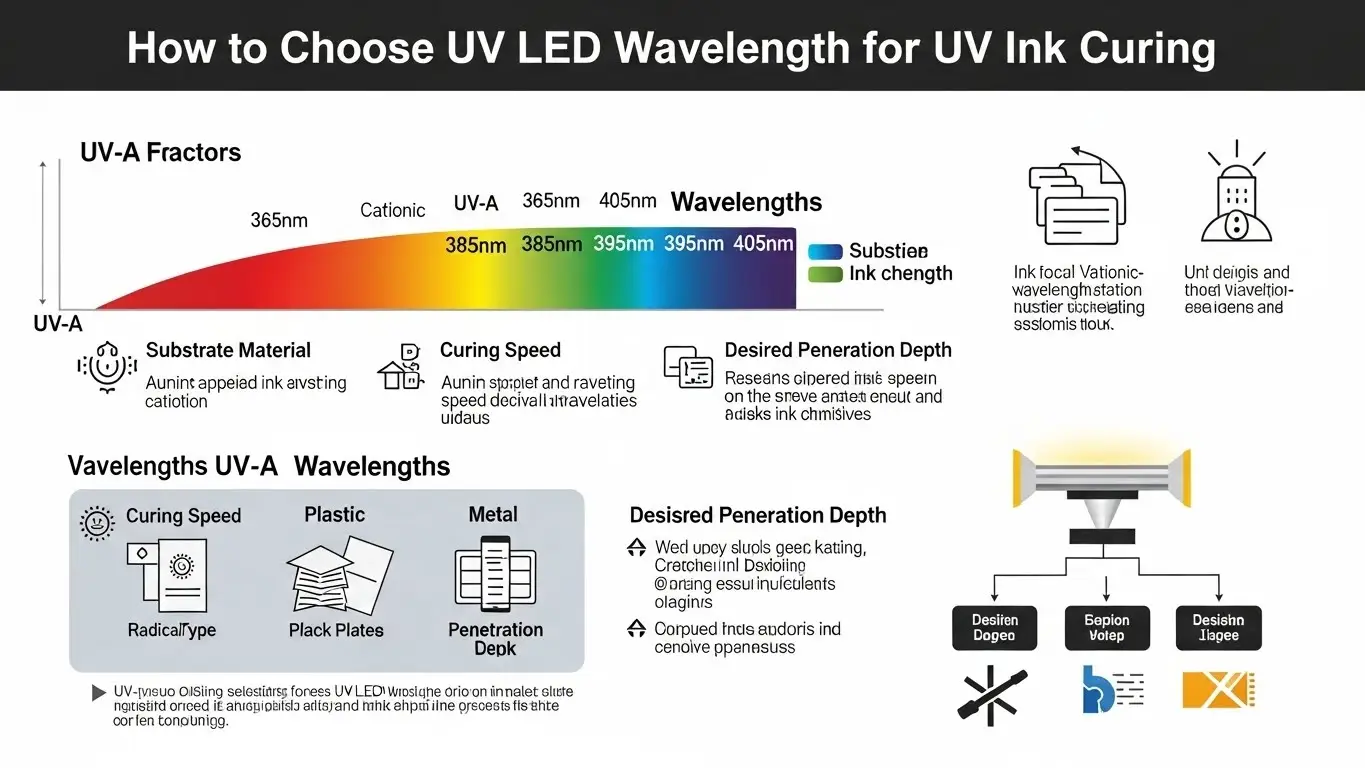

Air cooling is generally sufficient when duty cycles are moderate, power levels are within typical ranges, and thermal loads do not exceed what air flow can manage. You should consider air-cooled lights for applications like manual assembly stations, conveyor speeds that allow for lamp "off-time" between parts, or lower-intensity coatings. If your process does not require the absolute maximum irradiance of the LED technology, an air-cooled system often provides all the energy needed without the overhead of a liquid chiller. It is an ideal fit for clear adhesives and thin-film inks where the heat load is naturally lower.

How Does Air Cooling Influence Performance and Output?

Air-cooled systems influence performance by managing heat with airflow, which can maintain consistent intensity and uniformity under appropriate load but may limit top-end continuous power compared with liquid cooling. You may observe that for high-intensity arrays, air cooling requires larger lamp housings to accommodate the necessary fans and heat sinks. The uniformity of the cure can also be affected by how evenly the air moves across the diode array; any "stale" air pockets within the housing can lead to localized hot spots. While highly reliable, air-cooled systems are more sensitive to the ambient temperature of your factory floor.

What Practical Criteria Should You Use When Choosing Air-Cooled Systems?

Choosing an air-cooled UV LED curing light should be guided by factors such as expected duty cycle, ambient conditions, required output intensity, and maintenance capabilities. You should perform a technical audit of your environment and process using the following checklist:

- Duty Cycle: Is the lamp on for short bursts or continuous 24/7 cycles?

- Irradiance Needs: Does your material cure effectively at moderate power levels?

- Space Constraints: Do you have room for an external chiller, or is a self-contained unit required?

- Ambient Air Quality: Is the factory air clean, or will dust frequently clog the intake fans?

- Integration Ease: Does your machinery have the electrical capacity to power fans alongside the LEDs?

What Are the Common Trade-Offs With Air Cooling?

Common trade-offs with air cooling include reduced thermal headroom for very high power or extended continuous use, and a reliance on airflow that can be affected by ambient conditions. You get the benefit of lower initial costs and a smaller facility footprint, but you must accept that the system may drift more than a liquid-cooled equivalent during intense runs. Furthermore, air-cooled units can be noisier due to the high-RPM fans required to move enough air to manage the heat. If your process involves extremely high-intensity coatings, the thermal limits of air might necessitate slower production speeds.

How Does Maintenance Tie Into Air-Cooled System Performance?

Maintaining an air-cooled UV LED curing light means keeping airflow paths clear, fans operating, and heat sinks clean to support consistent heat removal and uptime. You must prioritize the cleanliness of the air intake filters, as any restriction in airflow immediately raises the internal temperature of the LEDs. Over time, dust can accumulate on the internal cooling fins, reducing their ability to transfer heat to the passing air. Regular inspections ensure that the fans are spinning at their rated speeds and that the lamp continues to operate within its optimal thermal window, protecting your equipment investment.

What Are the Key Takeaways on When Air Cooling Is Enough?

Air cooling is a robust and efficient solution for manufacturers who need reliable UV energy without the complexity of liquid plumbing. It is a standard for flexibility and simplicity in moderate-to-high power industrial curing.

- Best for moderate duty cycles and space-constrained production lines.

- Offers a lower Total Cost of Ownership by eliminating chillers and hoses.

- Requires a clean ambient environment to maintain peak cooling efficiency.

- Performance remains stable when intensity demand stays within air's thermal dissipation capacity.

What System Specifications Affect Cooling Requirements?

System power and diode density dictate how much heat must be moved. Learn more about interpreting UV LED curing system specs to see if air cooling fits your gear.

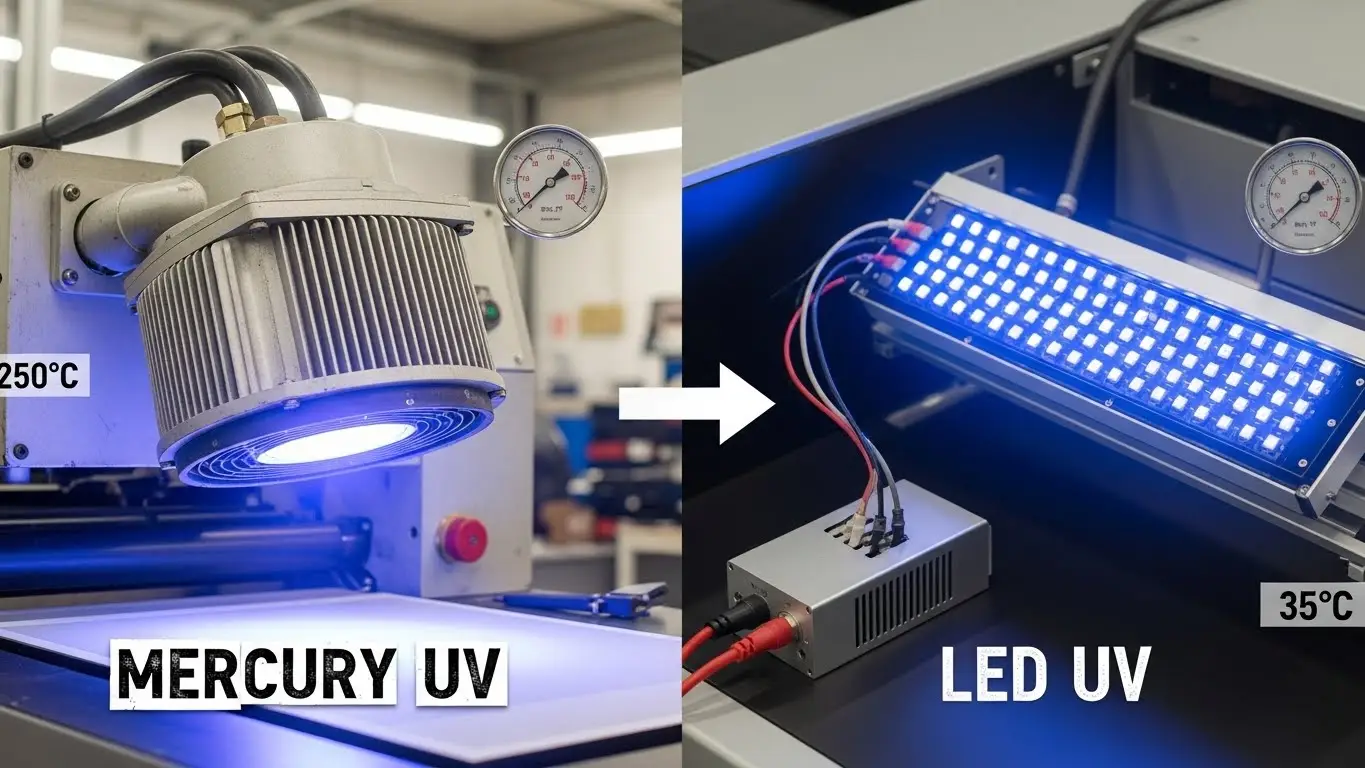

How Do Water-Cooled and Air-Cooled Systems Compare?

Choosing between the two depends on your intensity "ceiling." Review our side-by-side comparison of cooling methods for more context.

How Does Water Cooling Work for UV LED Curing?

If you suspect your process might be too intense for air, explore the mechanics of UV LED water cooling to understand the alternative.

How Does Intensity Influence Temperature and Cooling Stress?

Higher irradiance leads directly to higher thermal loads. Read about how UV LED intensity levels affect your lamp's heat generation.

How Do Dose Requirements Tie Into Cooling Strategy?

Longer exposure times lead to higher heat accumulation. Use our guide to calculate UV LED dose to help manage your system's duty cycle.

How Does Uniformity Interact With Thermal Management?

Uneven heat can cause uneven light output. Review why UV LED curing uniformity is a critical metric for air-cooled hardware.

Why Does Lamp Temperature Matter for Air-Cooled Systems?

Monitoring your operating environment protects your diodes. Explore the relationship between lamp temperature and performance for air-cooled setups.

What Maintenance Practices Support Air-Cooled System Reliability?

Keeping the fans and fins clean is the key to uptime. Follow our UV LED curing system maintenance checklist for air-cooled lights.

Final Thoughts

Finalizing your decision to use an air-cooled UV LED system is often a choice for simplicity and reliability. While liquid cooling is necessary for the extreme high end of the power spectrum, air cooling provides an elegant solution for the vast majority of industrial bonding and coating tasks.

By ensuring your ambient conditions are managed and your filters are kept clean, you can enjoy years of stable performance with minimal maintenance. The best cooling strategy is the one that provides exactly enough thermal stability to meet your quality specs without adding unnecessary bulk to your production line.