UV LED for Automotive: Advanced & Efficient Solutions

UV LED for Automotive Cures headlight coatings, dashboard adhesives, and EV battery seals with low heat to prevent substrate damage. Enhances durability in extreme temperatures.

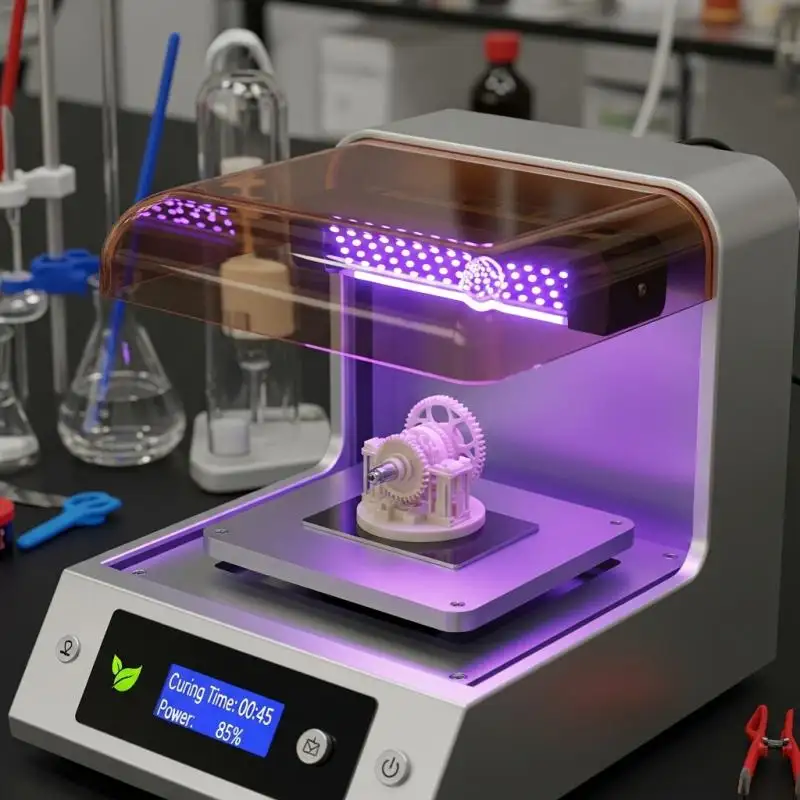

What is UV LED Curing?

UV LED for automotive refers to the process of curing (drying or hardening) coatings, inks, adhesives, and sealants using light emanating from diodes (LEDs) to ultraviolet (UV) light. Compared to traditional mercury UV lamps, UV LED systems operate at lower temperatures, consume less energy, and have more precise output at specific wavelengths. These benefits are ideal for sensitive substrates and for complex automotive applications.

Key Applications in the Automotive Industry

We have adopted UV LED curing technology in numerous processes throughout automotive manufacturing. Applications requiring low heat and high-strength bonding take the most advantage of it. Key applications are listed below:

1. Headlight Coating Curing

UV LED systems cure anti-fog and protective coatings on polycarbonate headlight lenses. These coatings assist with clarity enhancement, durability, resistance to UV, and elongation to break. Manufacturers can apply UV LED curing to improve production speeds and ensure uniform finishing without the adverse effects of warping heat-sensitive plastic parts.

2. Dashboard Adhesive Bonding

Dashboards today are made out of multi-material assemblies. UV LED curing, absorbs infallible and climate control interfaces under the steering consoles during dashboard construction in infotainment display mounts. The low heat output allows for the detention of fractures to fragile electronic components, enabling adhesion.

3. Sealing of Electric Vehicle Batteries

Dust, moisture, and temperature changes are threats that require vehicle batteries to be sealed securely. The performance and safety of electric automobiles are greatly improved using UV LED technology since curing adhesives and seals is completed quickly and uniformly. Its Compact design allows the curing equipment to be integrated into automated assembly lines of electric automobile batteries, enhancing efficiency.

The Importance of Low Heat

Traditional UV systems make use of UV lights to cure modifiers, use extreme temperatures of energy for adhesives, and this results in severe damage to sensitive components, like shattered window panes and heat-damaged components. UV LED curing, on the other hand, uses a controlled heating method, which is perfect for heat-sensitive substrates like plastics, electronics, and composite materials. All of which are staples in the automotive industry.

Using thermally sensitive substrates, plastics and composites, adhesives and coatings, UV LED systems:

• Lowers chances of warping and cracking.

• Reduces thermal stress on substrates.

• Improves the use of lighter, composite, and thinner materials.

• Improves operator safety and energy efficiency.

Greater Resistance to Damaging Conditions

Every automobile component endures extreme conditions. These include, but are not limited to, high engine temperatures and weather below zero. Coatings and adhesives that are cured using UV LED to yield coatings and adhesives provide superior performance over time.

Applications achieve:

• Increased mechanical and thermal strength.

• Increased lifespan of products, even in harsh environments.

• Long-term exposure to chemicals and UV rays responsibly.

Sterilization and Biocompatibility

UV LED systems are adaptable and can be integrated into diverse functions in automotive and peripheral industries, such as:

- Sterilization:

Surface cleaning and disinfection UV-C LED modules are important in the disinfecting process of surfaces in automotive HVAC, and air purification systems.

- Biocompatible Bonding:

UV LED curing can be permitted in non-harmful medical-grade bonding applications like the skin-contact surfaces of vehicle interiors.

- Compact Form Factor for Easy Integration

Implementation of manufacturing facilities is a premium. As such, the compact form factor of our UV LED systems means that they can easily be integrated into production lines, robotic arms, or conveyor systems. Their lightweight design makes maintenance, installation, and cost-effective.

NUVIA Devices in Action: Efficiency Redefined

Our customers from around the world have incorporated NUVIA devices, greatly improving their production efficiency and product quality. Here’s how our customers are benefiting:

- Automotive electronics affiliates are now achieving better precision (on touch screen panels) while eliminating over 50% of adhesive curing time.

- Seaming defects and thermal resistance have improved sharply, with EV battery manufacturers reporting consistent sealing.

- Flawless coatings are now the order of the day for OEM producers of headlight, enhancing surface durability and reducing waste.

Why Trust UVET When It Comes To UV LED Curing?

It’s no wonder UVET stands out as an industry leader for UV LED curing, and that’s because of their over a decade of experience. This is what sets us apart:

- Broad Industry Coverage

With more than UVET’s decade of R&D and manufacturing, UVET is knowledgeable regarding the industry and the technology of UV LEDs utilized in the automotive sector.

- Multi-Level Customization

The majority of production lines globally differ from each other. UVET enables customization of the following parameters:

• Wavelengths for specific adhesives and or coatings.

• Power output for an increase in curing requirements.

• Cooling, like simple air-cooling for less demanding setups or high-power systems that require cooling water.

- Comprehensive Quality Assurance

Adheres to international standards such as:

• CE – safety compliance.

• ROHS – environmental sustainability.

• ISO – quality management.

Reliable performance and peace of mind for customers across the globe.

Increased Technical Support

Along the entire process from design to after-sales, our professional staff is there to assist you. This also includes:

• System integration advice.

• Operator instruction.

• Support for unattended technical issues to ensure maximized system uptime.

Energy-Efficient UV LED Technology

Our curing technology has passed a milestone with the new generation UV LEDs systems. They provide significant benefits when compared to mercury vapor lamps:

• Reduce energy consumption by up to 70%.

• Longer operational lifespan with minimal maintenance.

• No warm-up needed with instant on/off control.

• Greater curing efficiency.

Conclusion

With unmatched support and years of experience in the field, UVET is not just a contractor; instead, the name provides innovation geared towards the clients. Explore UVET’s solutions on automotive advanced manufacturing and step forward with the industry. Remember, automotive UV LED curing is leading a revolution in vehicle components such as EV battery modules, dashboards, and headlights. Enhanced and improved product quality, cost reduction, and holistic manufacturing sustainability epic enabled with UVET’s technology.