Battery-Operated UV LED Curing Light: What to Expect

Integrating portable technology into your assembly or repair workflow requires a clear understanding of how cordless power impacts ultraviolet output. A battery-operated UV LED curing light provides the freedom to perform high-precision bonding in locations where traditional power outlets are unavailable.

This guide explores the performance benchmarks you should anticipate, from irradiance levels to thermal stability. By learning how to manage battery life and wavelength matching, you can maintain factory-quality standards during remote service or on-site manufacturing tasks.

What a Battery-Operated UV LED Curing Light Is

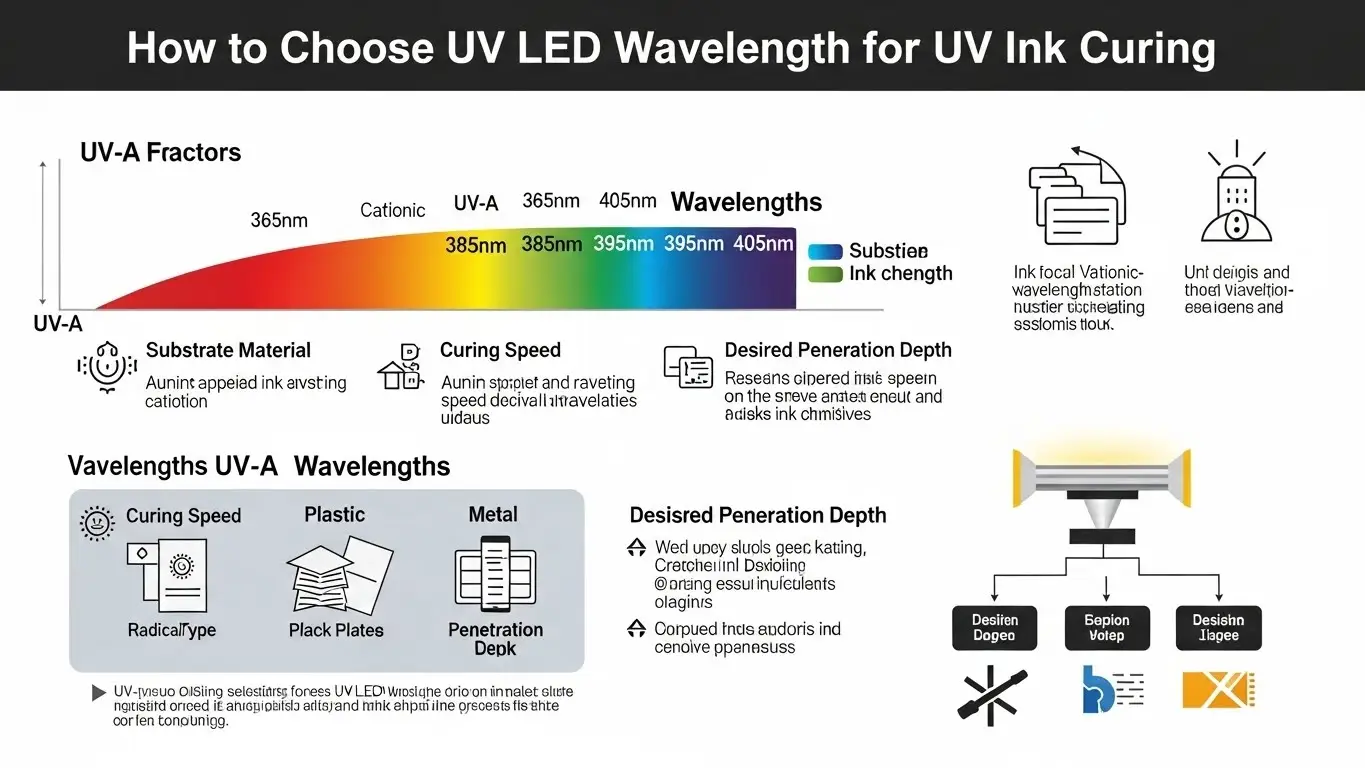

A battery-operated UV LED curing light is a portable ultraviolet LED tool powered by onboard batteries that delivers controlled UV energy to cure adhesives and coatings without tethered power. You will find that these devices utilize high-capacity lithium-ion cells to drive LED arrays, typically emitting narrow-band light at 365 nm, 385 nm, or 395 nm.

Because these units eliminate the need for heavy ballasts and trailing cables, you can use them for intricate repairs in tight spaces or on large structures like aircraft wings and wind turbines. The cordless design focuses on providing immediate, high-intensity UV energy exactly where your project requires it, making it a staple for field technicians and mobile maintenance teams.

What Performance to Expect From a Battery UV Curing Light

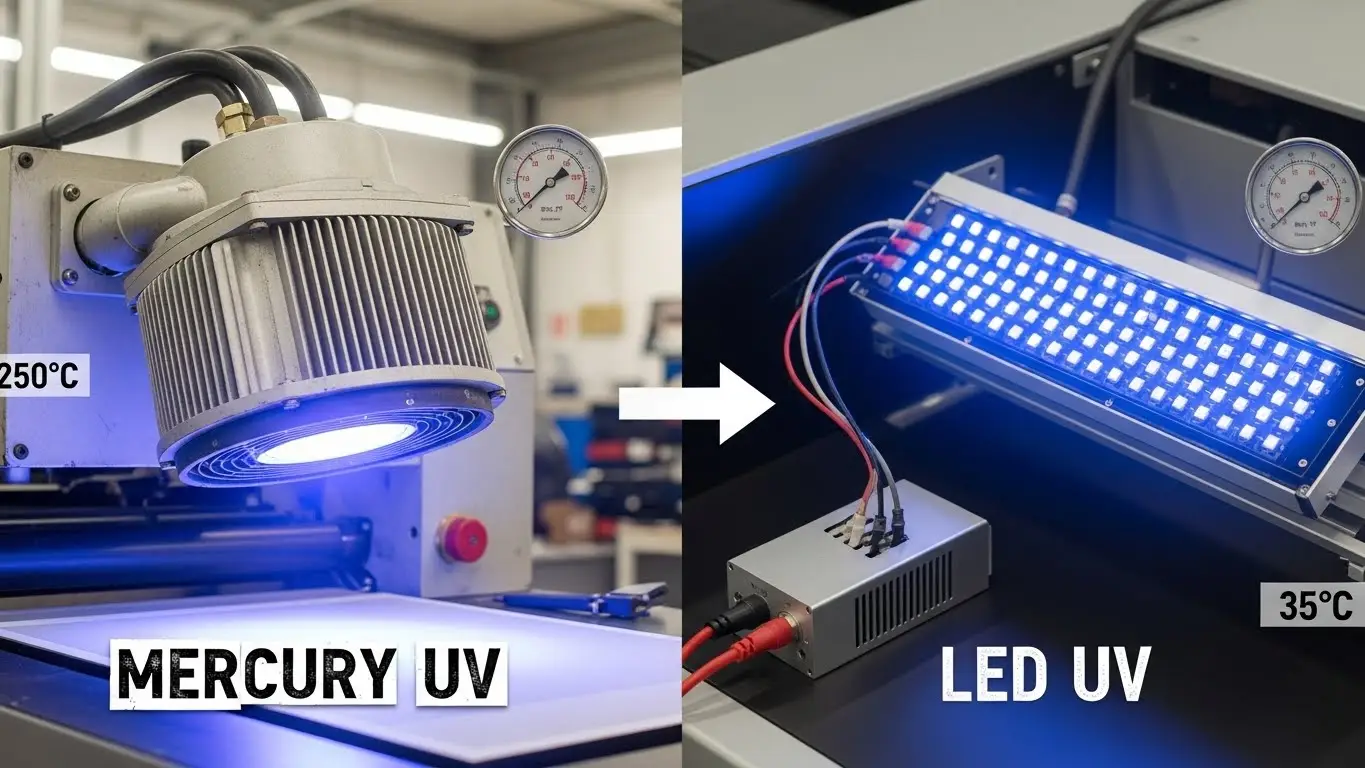

Performance from a battery UV LED curing light depends on LED intensity, battery capacity, and wavelength match with the adhesive, which determine how fast and how deeply materials cure. You should expect these portable units to deliver a lower peak irradiance ($W/cm^2$) than high-power, water-cooled industrial systems.

While stationary units might reach 20 $W/cm^2$, a high-quality battery lamp typically offers between 2 $W/cm^2$ and 8 $W/cm^2$ at the lamp head. This difference means your exposure times may be slightly longer, but the light is more than sufficient for curing clear adhesives and thin-film coatings. You must monitor the battery level, as some models may experience a drop in UV output as the charge nears depletion.

When Battery UV LED Curing Lights Excel

Battery UV LED curing lights excel in field repairs, small part assemblies, and situations where mobility and flexible placement matter more than high throughput. You will find them most useful when you need to "tack" a part in place or bond a small sensor housing in a remote industrial setting.

These lights are a superior choice for onsite maintenance where dragging an extension cord through a facility would create a trip hazard or logistical bottleneck. They are also perfect for R&D labs and manual workbenches where operators frequently move between different stations and need a light that is always ready to use without a complex setup.

What Limitations to Plan for With Battery UV Curing Lights

Battery UV LED curing lights have limitations including limited run time per charge, lower intensity compared with stationary units, and smaller effective cure area. You can generally expect 30 to 60 minutes of continuous "on-time" per charge, which requires you to plan for battery swaps if your production shift involves heavy use.

The heat management in these compact units is often passive or fan-based, meaning they may trigger a thermal shutdown if run at maximum power for extended periods without a break. You should also consider that the focused beam is usually limited to a spot size of 10 mm to 30 mm, making them less suitable for wide-area surface coatings or high-volume conveyor lines.

How to Get Consistent Results With a Battery UV Curing Light

Consistent results with a battery-operated curing light come from choosing the right wavelength for the adhesive, maintaining proper distance, and planning exposures based on intensity and cure requirements. You can improve your bond reliability by following these technical steps:

- Standardize Working Distance: Use a spacer or guide to keep the lamp at a fixed height, as intensity drops significantly if you pull the light away from the surface.

- Confirm Your Wavelength: Ensure the LED spectral peak matches your adhesive's photoinitiators (e.g., use a 365 nm lamp for a 365 nm resin).

- Track Battery Status: Use units with digital charge indicators to ensure you are not curing with a low-voltage battery that might produce weaker light.

- Manage Duty Cycles: Turn the light off between parts to prevent heat buildup and preserve the charge for when you actually need it.

What Are the Key Takeaways on Battery-Operated UV LED Curing Lights

Battery-operated UV LED curing lights provide mobility and practical curing performance for field and small-area tasks, but you should balance convenience with planning around intensity and battery life. Successful use relies on understanding the relationship between portable power and chemical reaction time.

- Cordless Freedom: Best for remote repairs, field service, and tight-space assembly.

- Lower Peak Intensity: Expect slightly longer cure cycles compared to mains-powered systems.

- Battery Management: Plan for recharges or spare packs during long production shifts.

- Precision Use: Ideal for spot bonds and small repairs rather than wide surface area coverage.

What Types of UV LED Spot Curing Systems Relate to Battery Units?

What types of UV LED spot curing systems exist and how do battery units compare? You can find more information on the UV LED spot curing system or explore wider spot curing options to see how cordless units fit into the broader hardware spectrum.

How Do Handheld UV LED Curing Lamps Work and Affect Expectations?

How do handheld UV LED curing lamps operate? Understanding the usage of handheld UV LED curing lamps and their operational mechanics will help you set realistic goals for your portable curing projects.

How Does Wavelength Choice Affect Battery Curing Performance?

How does matching UV LED wavelength to adhesive chemistry affect curing effectiveness? Choosing the correct UV adhesive curing wavelengths is the most critical technical step for ensuring a deep, thorough bond with a battery-powered light.

How Does UV Cure Time Vary With Intensity and Conditions?

How does cure time change with intense vs. moderate output? Review our guide on UV adhesive curing time to see how to adjust your exposure duration when using a portable, battery-operated source.

What Is Tacky Cure and How Can Battery Lights Influence It?

What is tacky cure and how does it relate to battery power? A tacky cure often occurs when the surface intensity is too low to overcome oxygen inhibition, which is a key consideration when planning your portable curing technique.

What Safety Gear Should You Use When Operating Battery UV Curing Lights?

What safety gear should operators use with battery UV LED curing lights? Protecting your eyes and skin with proper UV LED curing safety gear is mandatory, as the intensity of portable LED beams is still high enough to cause serious ocular damage.

Final Thoughts

Finalizing your approach to battery-operated UV curing means finding the balance between mobility and the technical dose required by your adhesive. While these tools offer unmatched flexibility for field work and specialized assembly, they require your attention to battery levels and working distances to ensure consistent quality. By treating the battery lamp as a precision instrument, you eliminate the risk of under-cured bonds during remote repairs. A well-maintained cordless lamp ensures that your on-site work is just as durable and permanent as any factory-produced component.