Can Battery UV Curing Lights Work for Field Repairs?

In the world of field service and on-site maintenance, the lack of accessible power can bring high-precision bonding tasks to a standstill. Traditionally, technicians were tethered to stationary workstations, but the advent of high-capacity lithium-ion technology has changed the landscape of ultraviolet assembly.

This guide explores the effectiveness of battery UV curing lights for field repairs, examining how these cordless tools balance the need for portability with the technical requirements of industrial adhesives. By understanding the capabilities and limitations of portable LED systems, you can ensure that your remote repairs meet the same structural standards as those performed in a factory.

What Are Battery UV Curing Lights?

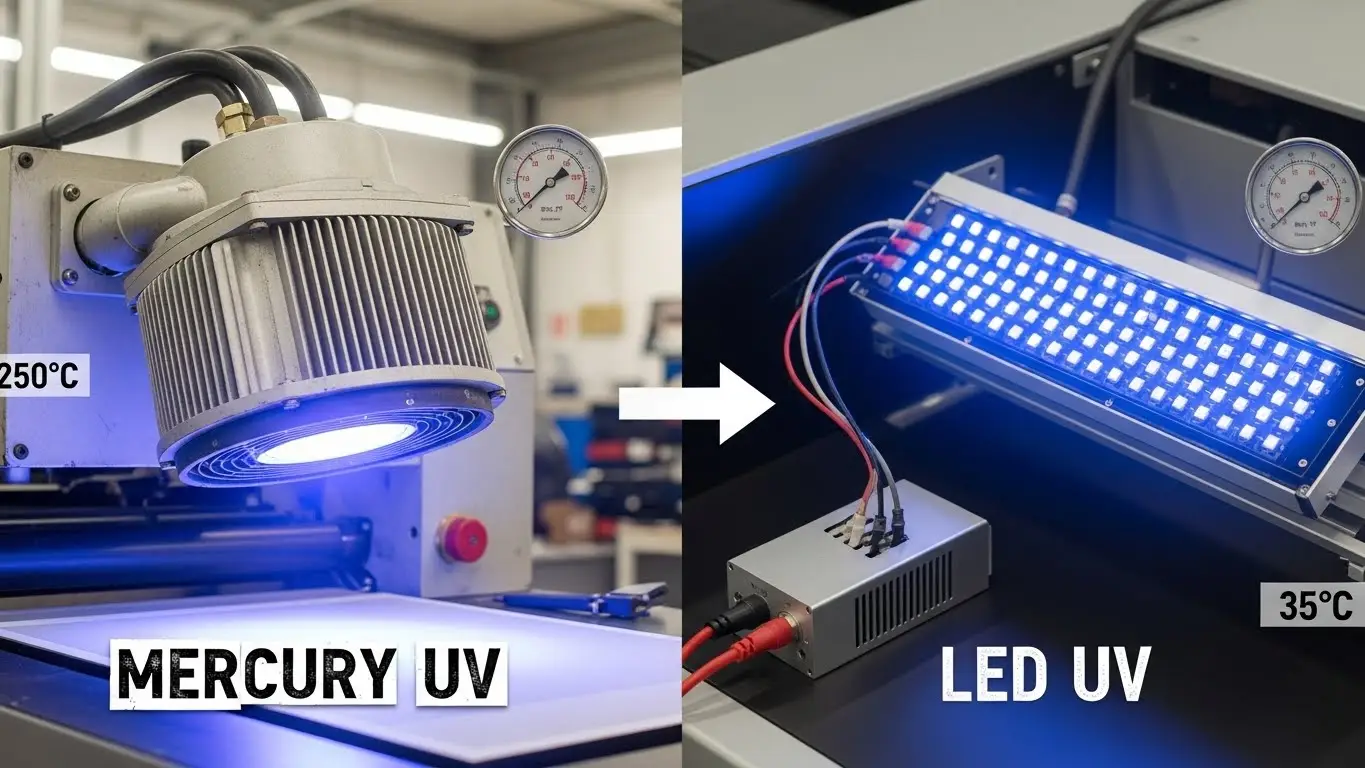

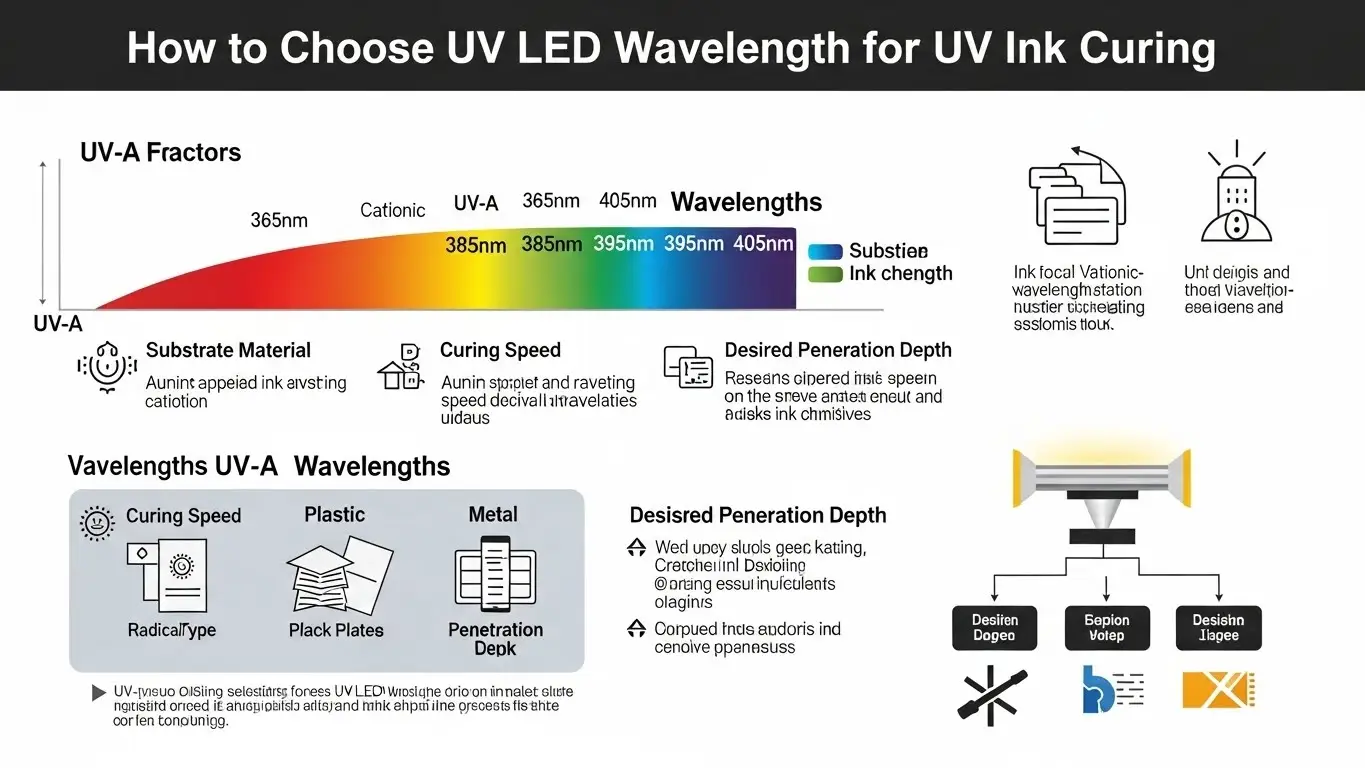

Battery UV curing lights are portable, cordless ultraviolet LED tools that deliver focused UV energy to cure adhesives, coatings, and other UV-reactive materials without needing a direct power connection. You will find that these devices typically utilize high-density LED arrays powered by rechargeable batteries to emit narrow-band UV light, most commonly at 365 nm or 395 nm.

Unlike traditional mercury lamps that require warm-up times and heavy ballasts, these solid-state tools offer "instant-on" capability and a lightweight form factor. This design allows you to bring the light directly to the repair site, whether it is atop a wind turbine, inside a vehicle chassis, or in a remote telecommunications hub where trailing cables would present a significant safety hazard.

Why Battery UV Curing Lights Are Useful in Field Repairs

Battery UV curing lights are useful in field repairs because they let operators cure adhesives without relying on stationary power, improving flexibility and convenience on site. You no longer have to worry about finding an outlet or running long extension cords through complex industrial environments, which significantly reduces setup time and enhances mobility.

These tools provide a rapid solution for "tacking" parts into place or performing small-area repairs that would otherwise require moving the entire assembly to a specialized curing station. For technicians working in dynamic or hazardous environments, the ability to achieve a full structural cure in seconds without a tethered power source is a major contributor to operational uptime and efficiency.

What Types of Field Repairs Benefit Most From Battery UV Curing

Battery UV curing lights are especially effective for field repairs that involve bonding small parts, fixing assemblies in tight spaces, or performing quick onsite fixes where access to mains power is limited. You will find them frequently used in the electronics industry for securing wire harnesses or repairing sensor housings where precision is paramount.

They are also a standard choice for glass and plastic bonding in automotive and aerospace maintenance, where the repair area might be physically difficult to reach with a standard lamp. Other common applications include fixing composite cracks, sealing gaskets, and securing dental or medical components during mobile service calls where a compact, high-intensity source is required.

What Limitations Should You Expect With Battery UV Curing Lights

Battery UV curing lights have limitations, including limited run time per charge, dependence on correct wavelength matching, and reduced curing area compared with larger mains-powered systems. While modern batteries are powerful, the high-current draw required to maintain peak UV intensity means you may only get 30 to 60 minutes of continuous operation before needing a recharge.

Furthermore, the irradiance ($W/cm^2$) of a battery-powered unit may be lower than that of a water-cooled industrial flood lamp, which can lead to longer cure times for thick or pigmented resins. You must also be diligent about monitoring the state of charge, as some entry-level units may exhibit a drop in light output as the battery voltage diminishes, potentially leading to under-cured bonds if not properly accounted for.

How To Get Consistent Results With Battery UV Curing in the Field

Consistent field curing with battery UV lamps depends on choosing the right wavelength, maintaining proper lamp-to-surface distance, and planning exposures based on adhesive specifications. You can achieve factory-level results by adopting a structured protocol for every remote repair:

- Verify Battery Levels: Always start a repair with a fully charged battery to ensure the lamp delivers its rated peak intensity throughout the cure cycle.

- Standardize Distance: Use a spacer or guide to keep the lamp at the manufacturer-recommended working distance, as moving the lamp just 10 mm away can significantly reduce the energy dose.

- Shield the Work Area: In bright outdoor environments, use a UV-opaque shroud to prevent ambient sunlight from pre-curing the adhesive before you have properly aligned the parts.

- Use Timed Exposures: Avoid "guesstimating" the time; use the lamp’s internal timer or a stopwatch to ensure the adhesive receives the exact Joules per square centimeter ($J/cm^2$) required.

What Are the Key Takeaways on Battery UV Curing Lights for Field Repairs

Battery UV curing lights can be effective for field repairs when used with appropriate adhesives and proper technique, though they come with practical constraints compared with larger systems. Portability does not excuse the need for technical precision regarding wavelength and distance.

- Cordless mobility is the primary advantage for remote, high-altitude, or tight-space repairs.

- Wavelength alignment remains critical; the lamp must match the adhesive’s photoinitiators.

- Battery management is essential to prevent intensity drift during long production shifts.

- Technique is everything: Fixed distances and timed exposures ensure repeatable bond strength.

What Portable UV LED Spot Curing Systems Exist and How Do They Compare?

Ask what types of portable UV LED spot curing systems exist and how they compare to battery-powered units for field work. While some UV LED spot curing systems are designed for benchtop use, there are portable, wand-based versions that provide higher intensity but require a tethered controller.

How Do Handheld UV LED Curing Lamps Work?

Ask how handheld UV LED curing lamps operate and what makes them practical for field repairs. Understanding the usage of handheld UV LED curing lamps and their general operational mechanics helps you choose a tool with the right ergonomics and thermal management for your specific field tasks.

How Does Wavelength Selection Affect Field UV Curing Speed and Quality?

Ask how matching UV wavelength to adhesive needs impacts cure speed and consistency in field environments. Selecting the correct UV adhesive curing wavelengths is the most vital technical decision, as the wrong frequency will result in soft or tacky bonds regardless of portability.

How Does Cure Time Change With Different Conditions in the Field?

Ask how environmental factors and UV intensity affect the time required to cure adhesives in field settings. Variations in UV adhesive curing time are often caused by the distance from the lamp or temperature fluctuations, making it essential to calibrate your timing based on on-site measurements.

Final Thoughts

Finalizing your field repair strategy with battery UV lights is a step toward greater operational flexibility without sacrificing quality. While these tools offer unmatched freedom of movement, their success is governed by the same physics of light and chemistry as stationary industrial lamps. By focusing on the spectral match between the LED and the adhesive and maintaining a disciplined approach to battery maintenance, you eliminate the risks associated with remote repairs. A well-executed battery-powered cure ensures that your on-site work is just as durable and permanent as any factory-produced assembly.