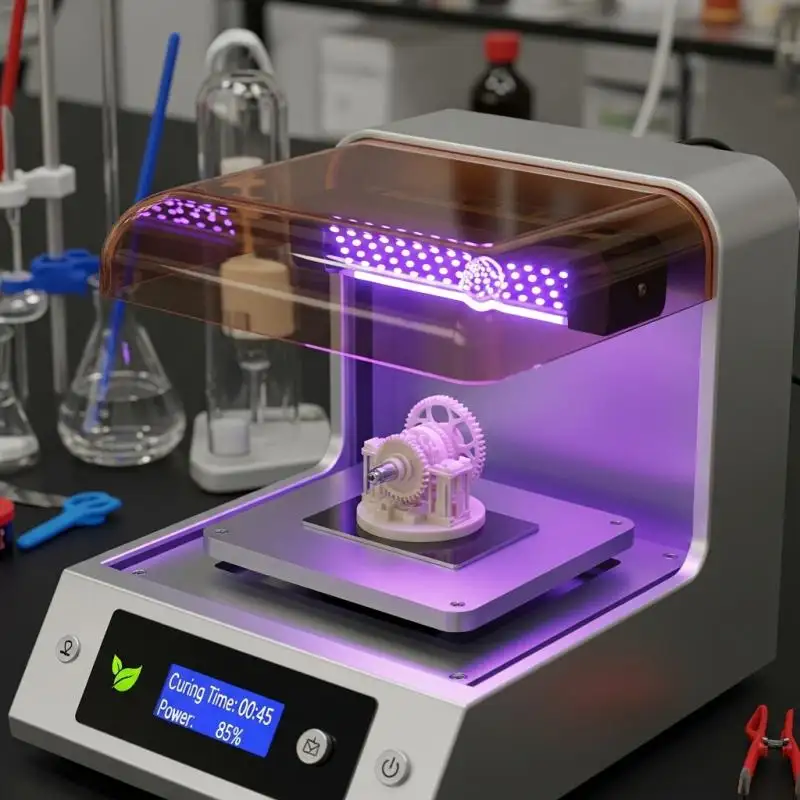

Bench-Top UV System: Accuracy, Economy, and Flexibility in the Modern Curing.

Precision and efficiency are the most important in the contemporary industrial and laboratory world, where time is of the essence. The bench-top UV technology has become a pillar technology in a range of applications, including laboratory research and 3D printing, and smaller production in industry. These systems can be used to produce high-quality and consistent polymerization of UV-sensitive materials; this is made possible by UV technology through the process of curing.

You might want to improve the bench-top UV curing processes, better the polymer adhesion, or even shorten the curing time; it is imperative to know the capabilities of the current UV bench-top curing systems. These tiny, all-purpose units provide unmatched control of curing parameters and thus are invaluable in laboratories, prototype production units, and small-scale production units.

What is a Bench-Top UV System?

A bench-top UV system is a small, self-contained unit that is used to cure UV sensitive materials by using UV LED bench-top units or other UV sources. As opposed to large-scale curing machines, they will be used on the desktop, allowing controlled conditions to be used to photopolymerize systems, cure polymer using UV, and cure UV coating.

The main features of a system are:

UV lamp: This is the main UV source that may be an LED or mercury.

Exposure chamber: Has to do with the uniformity of irradiating the material.

Intensity control: Intensity control of the UV lamp is highly adjustable to bench-top applications to accommodate various materials.

Cooling and protection functions: Keep the optimal operation and safeguard users against UV radiation.

These systems can be used in high-resolution curing, scratch-resistant finishes, and high-speed UV curing process thus highly versatile in various industries.

How Bench-Top UV Systems Work?

A bench-top UV curing machine works on the principles of UV polymerization and photoinitiation. When the proper wavelength and intensity of UV light are applied to UV-sensitive materials, e.g., UV-curable resins or rapid curing inks, a chemical reaction will take place and make the material hard within seconds.

The bench-top UV LED system allows strict regulation of the curing parameters:

UV Intensity Adjustment - Operators are able to adjust the intensity of light to fit various UV-sensitive media.

Exposure Time Control - Fine-tuning exposure - Fine-tuning exposure will guarantee full curing without exposing it to excess.

Smooth Irradiation - The design will ensure a smooth, uniform curing process throughout the surface.

Cooling Management - Advanced bench-top UV ovens or LED units are used to eliminate heat damage to delicate substrates.

Applications

UV systems on the bench are the ones that cannot be done away with in various industries due to the versatility of the systems.

Laboratory Research and Development

A desktop UV system can offer a controlled environment to research and development projects by testing new UV-curable resins, testing photoinitiators for UV curing, and conducting very careful experiments. Lab-grade units allow researchers to test the UV light exposure systems, and the results would be reproducible.

3D Printing

In 3D printing, bench-top UV 3D printing systems are an essential part of curing a resin in stereolithography (SLA) 3D printers or in digital light processing (DLP) printers. These systems enable layers to cure fast in a precise manner to produce smooth surfaces and dimensional accuracy.

Electronics and Industrial Applications

Small-scale industrial applications, eg, UV coating curing of electronics, are dependent on bench-top systems to obtain finishes that are consistent and high-speed polymerization. Small units enable the manufacturers to sustain quality and simultaneously reduce time wastage in production.

Dental and medical applications

The use of dental UV curing can be achieved through the bench-top systems that can offer accurate and high-intensity UV light to cure dental resins, adhesives, and coatings effectively. These units provide quick-drying UV systems that have variable intensity on delicate materials.

Advantages and Features

The contemporary UV curing machines in bench-tops are tailored to be precise, efficient, and flexible. The outstanding features are:

Fast-Drying UV System - Cuts down on the time of curing when used on large volumes.

Small UV Curing Solution - Small and can be placed on desktops or small laboratory tables.

Energy-Saving Bench-Top UV System - LED-based units use less power and offer consistent power.

Exposure Accuracy - Intensity and exposure time can be adjusted to maximize the curing.

High-Resolution Curing - Best use on fine work, including dental, electronics, and 3D printing.

Hard Surface Finishing - provides tough, anti-scratch, and resistant surfaces.

Purchasing the Right UV Bench-Top System

The selection of the appropriate bench-top UV system should be based on several technical parameters:

Wavelength Compatibility - Model system to correspond to the UV sensitivity of materials. There are regular wavelengths of LED units like 365nm, 385nm, and 395nm.

Lamp Intensity - Intensity is adjustable to obtain the desired uniform curing without excessive exposure of materials.

Cooling System - Fan-cooled units do not accumulate heat during long curing.

Integration and Portability - Compact systems must readily fit into the pre-existing lab or production systems.

State-of-the-Art Bench-Top UV Systems

Technology has been introduced to the modern desktop UV systems to improve performance and usability:

LED UV Bench-Top System: LED technology is used in curing systems that are more energy-saving and have longer lamps.

Inhibited UV Irradiation: Provides a consistent exposure, which will limit incomplete curing.

Quick UV Curing: Rapidly uses up high-viscosity resins.

Lab-Grade Resins Compatibility: Supports UV-sensitive material research use.

Precision Curing of Polymers: This is ideal with regard to photopolymerization bench UV systems in small-scale production.

UV System at the Bench for printed use

Bench-top UV printing systems offer a regulated miniature option of curing inks and smears in a miniature or home set-up. Operators can attain:

- Quick drying of UV inks in prototyping and short production.

- Vivid prints of high quality and color uniformity.

- Strong and damage-free label and packaging finishes.

They are ideal in research centers, print shops, and product development staff who require a good, dependable, and energy-saving system to test and produce.

High top 3D printing and prototyping bench-top UV systems?

Precision curing is important in 3D printing. 3D printing UV systems:

- Make sure that all the resin layers are cured homogenously.

- Reduce defects and warping caused by exposure misalignment.

- Provide the ability to control the intensity of the UV lamp depending on the type of resin.

Prototyping becomes more dependable and quicker with a high-performance bench-top UV curing system, which lowers trial-and-error and waste of materials.

Conclusion

The bench-top UV is now a necessity in the laboratory, research, and small-scale operations in the industrial world. These systems provide accuracy, quick UV curing, and energy consumption, which means that they can produce high-quality outcomes in 3D printing, electronics, and dental printing.

With the appropriate choice of bench-top UV curing equipment and correct setting of its parameters, companies and scientists can enhance polymer adhesion, decrease the amount of time needed to cure the polymer, and obtain long-lasting, scratch-resistant finishes.

UVET LED UV Tape Curing Systems can be the solution of choice for those who require the ability to combine the reliability and efficiency of end-of-bench UV systems.

Get a bench-top UV system today and improve on precision, efficiency, and productivity in your lab or production workflow.