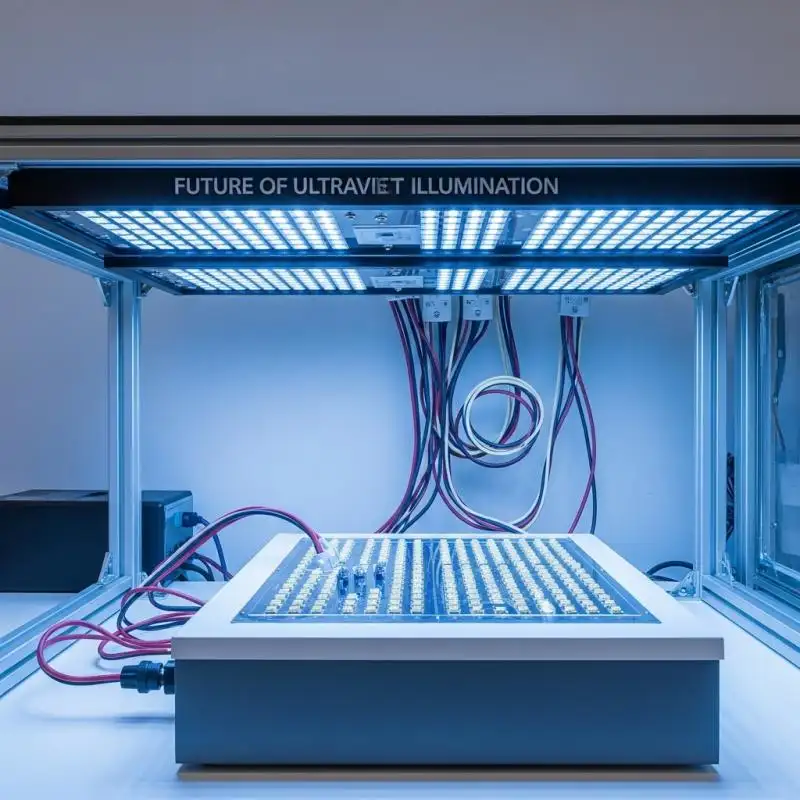

LED UV Inspection: Benefits, Applications, and Practices

High-Intensity LED UV Examination for Accurate Defect Detection

- When it comes to non-destructive testing (NDT), accuracy is everything. With the use of our high-intensity LED UV inspection lights, there is precise control over the 365nm UV-A wavelength emission, which is tuned for fluorescence, and the light output is constant. With this stable emission, fluorescent penetrant inspection (FPI) and magnetic particle inspection (MPI) processes are clearer and more thorough, thus increasing the possibility of defect detection by surface evaluation.

- From aerospace to automotive and medical device manufacturing, our sustained work on UV LED mark technology serves primary inspection processes. Switch on and work instantly; no pre-heating allows for smoother workflows, which is pivotal in industrial environments.

Construction Site and Cleanroom Ready With Industrial Strength Protection

- With IP65 features, our black lights are dust, water, and shock resistant, hence ensuring lasting durability in rugged workplaces such as construction sites and controlled environments like cleanrooms.

- Our rugged black lights greatly exceed old-school mercury vapor lamps, as our devices easily surpass 20000 hours of use. This device's ever-lasting UV irradiance with unquestionable inspection services results in cost-efficacy by refuting the need for frequent maintenance.

Inspection Solutions are Portable and UV-Safe.

- Inspections today require mobility without compromising on safety. Our portable UV inspection lamps are lightweight and cordless, featuring rechargeable batteries that allow for prolonged use without hindrance. This versatility enables on-site inspections of fluid leak detection and contagion control.

- Safety is equally important. The mercury-free LED technology used in our devices gives off very low heat and therefore lowers the chances of burns or damage to equipment during prolonged use. These lights, together with built-in UV-A pass filters, greatly reduce harmful UV radiation emitted to the operators, which ensures compliance with safety standards within the industry.

Variety Perfection Inspection applications

Our LED UV inspection lights support a wide range of industrial applications, including but not limited to:

• Aerospace and automotive parts crack detection.

• Pharmaceutical and medical device manufacturing cleanliness checking.

• Curing inspection of adhesives in electronic devices and coatings.

• Detecting hydraulic fluid and fuel leaks in hydraulic and fuel systems.

The special 365-395 nm wavelength range increases the fluorescence visibility of dyes and penetrants to be used in these tasks, making our lights essential sterilization, inspection, evaluation, and non-destructive evaluation (NDE) devices.

What Makes Our LED UV Inspection Equipment the Best Choice?

By choosing our LED UV inspection solutions, you get precision, longevity, and safety all at once. They are known all over the world for the high industrial performance of their UV illumination and comply with ASTM E3022 and ISO 3059 regulations.

For transforms on how our UV LED lamps can change your inspection processes, go to UVNDT, which is a leading supplier of modern UV inspection technology.

How Inspection By LED UV Works: Its Mechanics

As mentioned before, LED UV inspection employs the use of ultraviolet light technology to come in contact with fluorescent materials or substances that can be found on the objects under scrutiny. The metallic part of the mask absorbs UV-A light ranging from 320-400 nm, which is emitted by the lamp’s targets, and in turn, light energy is produced, which emphasizes flaws of any kind, be they cracks, leaks, or other problems.

Key Technical Terms:

• UV-A wavelength (365nm): The best-known wavelength of UV radiation for checking because it has the best ratio between stimulating fluorescence and damage.

• UV irradiance: The benefit of UV rays per unit area. It is very important to achieve unified results on several objects under inspection.

• Beam profile: The degree of distribution of the intensity of UV light of a lamp in the same direction affects the uniformity of the inspection results.

• Filters (Wood’s glass filter): Used to get rid of light that is capable of being seen and intensify the consonant constituents that are invisible.

Uses of LED UV for Inspection

Due to its versatility, LED UV inspection can be used in various industries and processes. Some of the most notable are outlined below.

1. Micro Crack and Surface Defects Inspection

Surface flaws and micro-cracks can result in serious safety and product integrity issues in aerospace, automotive, and other manufacturing industries. Fluorescent penetrant inspection (FPI) utilizing LED UV lamps allows for the visualization of even microscopic cracks due to the penetrant's illumination under UV-A light.

2. Fluid Leak Check

In hydraulic, pneumatic, and fuel systems, the detection of leaks is facilitated by the use of UV LED backlights in combination with fluorescent dyes. The fluorescent markings left by the leaks are visible during UV illumination, thus aiding the reduction of downtimes and maintenance expenditures.

3. Contamination and Cleanliness Validation

For cleanroom validation and medical device manufacturing, the use of LED UV light during inspection allows for confirming the absence of organic contaminants on surfaces to be cleaned. Since this method is non-destructive, it guarantees compliance with stringent cleanliness regulations.

4. Inspection of Curing of Adhesive and Coating

During the production processes, inspections are needed to confirm the curing of adhesives and coatings in UV curing processes (for instance, LED UV curing). LED UV lamps evaluate the completeness of the curing by checking fluorescence changes or if there are spots without uncured materials.

5. Security and Forensic Applications

UV light examination is also very important in the counterfeit detection of products, as well as for forensic assessment. Fluorescent inks and marking pens are only visible under UV light and thus form a reliable method of inspection for security purposes.

Benefits of LED UV Inspection Compared to Traditional Methods

There are several advantages to adopting LED inspection:

• Enhanced Energy: The use of mercury vapor lamps in the past was a significant cost in consuming energy while trying to emit UV rays, but now with LED UV lamps, this has drastically reduced.

• Longer Lifetime: Replacement frequency is minimal due to the long-lasting capabilities of emitting diodes (LEDs) lasting 50,000 hours.

• Reduced Heat Output: Less generation of heat facilitates the protection of sensitive materials during inspection.

• Portable Application: With battery power, portable UV inspection lamps can be used in the field, unrestricted by the availability of electricity.

• Reduced Threats to the Environment: Due to not containing mercury, LEDs reduce threats to the surrounding environment and dangers while disposing of materials.

• Added Safety: Risks of exposure to ultraviolet rays are minimized as LED ultraviolet (UV) devices can be fitted with shields and filters for built-in tend of these devices.

Selecting the Appropriate LED UV Inspection Apparatus

While choosing an inspection system, keep in mind:

• Most inspections require a 365nm LED UV light source to achieve optimal fluorescence emission.

• Handheld lamps are more mobile, whereas stationary lamps stay put in the lab.

• Battery-powered units allow flexible movement, while corded counterparts ensure constant operation.

• Light distribution should not lead to missing defects.

• Essential filters, ocular protective gear, and overall industrial safety compliance are important to safeguard the user from exposure.

Guidelines and Precautions for Working with UV Inspections

Safety measures must be taken when exposing the skin and eyes to UV light:

• Utilize safety goggles designed for UV ray blocking.

• Face and body protective coverings should be implemented.

• Limit contact with body skin.

•Handle tools that have integrated shields or filters.

What Makes UVNDT a Leader for LED UV Inspection Products?

At UVNDT, we offer advanced solutions in industrial UV lighting designed to meet diverse inspection needs. Our product range encompasses robust portable and handheld UV LED lamps, UV inspection equipment, and calibration equipment, all of which meet international standards. From aerospace crack detection and automotive leak inspections to forensic analysis, VIUNDT offers dependable, high-performance equipment backed by expert support.

Conclusion

LED UV inspection is transforming the application of non-destructive testing (NDT) and quality control across various industries. It has become a preferred method for identifying cracks, leaks, contamination, and curing defects due to its unmatched efficiency, precision, and environmentally friendly approach in aerospace, automotive, medical, and forensic fields. Following safety and calibration standards while investing in reliable UV LED light sources guarantees accurate and dependable results. For thorough ultraviolet inspection solutions, rely on UVET, leaders in innovative inspection technologies.