How to Choose UV LED Wavelength for UV Ink Curing

In the high-speed world of digital and offset printing, the transition to LED technology has revolutionized how we think about ink solidification. Achieving a perfect finish is no longer about simply "blasting" the substrate with light; it is a precise technical alignment between the ink's chemical photoinitiators and the spectral output of the LED array.

This guide explores the engineering principles behind choosing the UV LED wavelength for UV ink curing, helping you optimize your press for maximum adhesion, vibrant color consistency, and peak production speeds. By understanding how different wavelengths interact with pigments and resins, you can eliminate common print defects and ensure your output meets the rigorous demands of the packaging and commercial print industries.

Why UV LED Wavelength Matters for UV Ink Curing

UV LED wavelength matters for UV ink curing because inks contain photoinitiators that react only to specific UV wavelengths to form a solid film. You can view the wavelength as a "spectral key" that must fit the "chemical lock" of the ink formulation. If the photons emitted by your LED system do not align with the absorption peaks of the photoinitiators, the polymerization process will be inefficient or fail entirely.

When the wavelengths are mismatched, you may encounter issues where the surface of the ink feels dry, but the internal layers remain liquid. This lack of structural integrity leads to poor rub resistance and ink "picking" during post-press processes. Selecting a wavelength that effectively triggers the specific chemistry of your ink is the foundation of a stable and predictable printing environment.

How UV Ink Chemistry Influences Wavelength Choice

UV ink chemistry determines wavelength choice because different photoinitiators absorb energy most efficiently at specific UV bands. Unlike clear coatings, printing inks contain high concentrations of pigments and fillers that act as internal filters, often blocking or scattering shorter ultraviolet waves before they can reach the bottom of the ink layer.

If you are printing high-density blacks or opaque whites, you require a wavelength that can "see through" these pigments. Generally, longer wavelengths possess a greater ability to penetrate these dense materials. Your ink supplier’s technical data sheet is your primary resource for identifying the specific spectral sensitivity of your ink, ensuring that your light source provides the exact photon energy needed to initiate a deep, thorough cure.

What UV LED Wavelength Ranges Are Common for Ink Curing

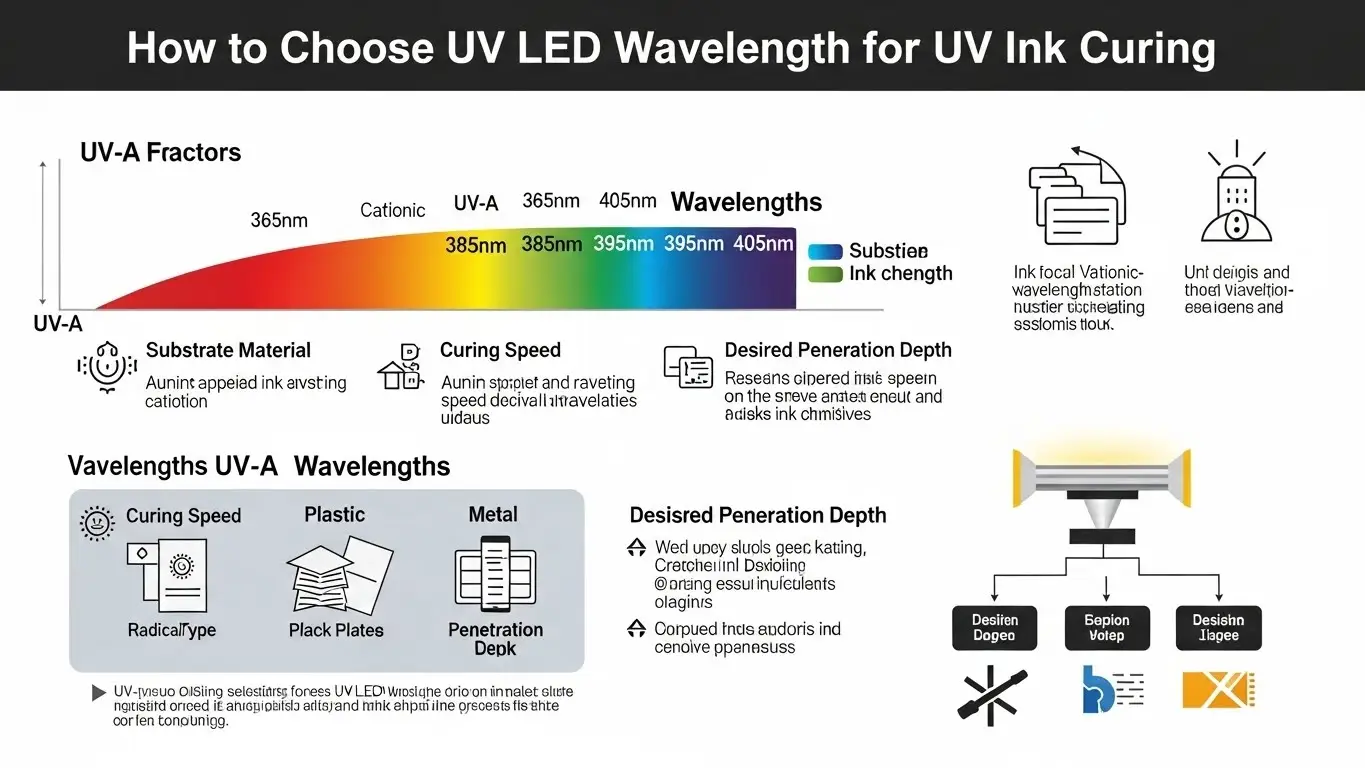

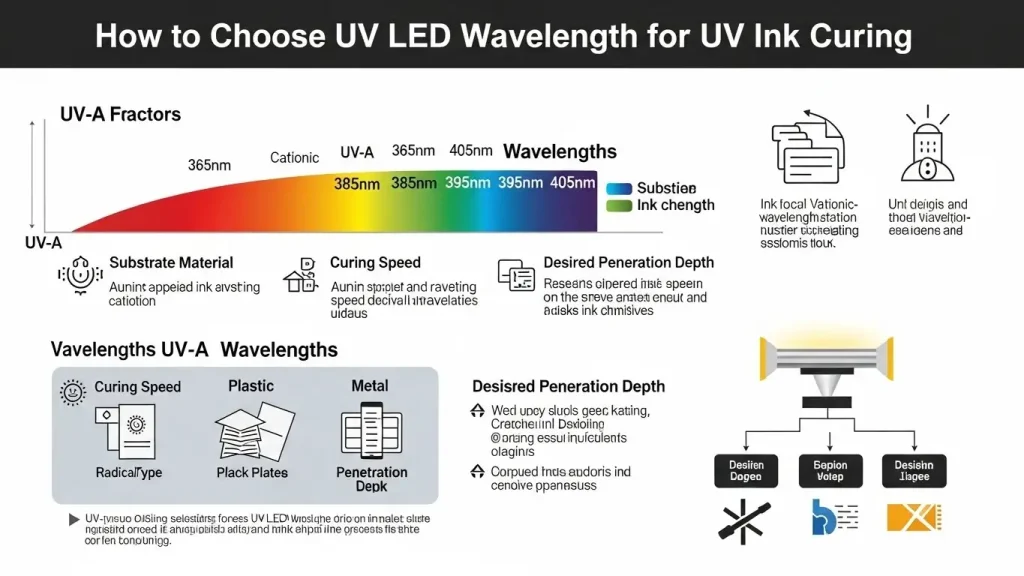

Common UV LED wavelengths for ink curing typically fall within the UVA range, with different bands offering tradeoffs between surface cure speed and penetration. Most industrial printing systems utilize 365 nm, 385 nm, or 395 nm LED arrays to accommodate various ink types and substrate speeds.

- 365 nm: This wavelength offers high photon energy, which is excellent for rapid surface hardening and overcoming oxygen inhibition. It is a preferred choice for clear overprint varnishes and thin-film labels.

- 385 nm & 395 nm: These longer wavelengths are the workhorses of the wide-format and digital inkjet world. They provide deeper penetration, which is vital for curing the thick, pigmented ink deposits found in high-quality graphic applications.

- 405 nm: Occasionally used for specialized coatings or for curing through substrates that block shorter UV frequencies.

How Wavelength Affects Cure Depth and Print Quality

UV LED wavelength affects cure depth and print quality by influencing how uniformly the ink cures through its thickness. If the wavelength is too short, it may be entirely absorbed by the surface photoinitiators, leaving the ink at the substrate interface uncured. This leads to a loss of adhesion where the entire ink film can be easily scratched or peeled away.

Conversely, if the wavelength is properly matched for penetration, the polymerization occurs consistently from the bottom up. This uniform cross-linking is what gives the print its final gloss level, chemical resistance, and flexibility. Mismatched wavelengths often result in "wrinkling" or "orange peel" textures as the top layer shrinks at a different rate than the liquid interior, permanently compromising the visual quality of your print.

How to Match UV LED Wavelength to Your Printing Application

Choosing the right UV LED wavelength requires aligning ink specifications, layer thickness, substrate type, and production speed. You should treat the curing process as a holistic system rather than a series of isolated components. For high-speed flexographic lines, you may need a high-intensity 395 nm system to ensure through-cure at 200 meters per minute.

For specialized labels on heat-sensitive films, a 365 nm system might be better to achieve a hard surface finish without over-heating the substrate. You should always perform a "cure ladder" test—varying the intensity and line speed—to validate the performance of a specific wavelength. Relying on visual dryness alone is dangerous; instead, use standardized tape tests or chemical rub tests to confirm that the ink has reached its full structural properties.

What Are the Key Takeaways for UV Ink Wavelength Selection

Selecting the correct UV LED wavelength is essential for achieving consistent ink cure, strong adhesion, and stable print quality. It is the most critical technical bridge between the liquid state of the ink on the press and its final performance in the hands of the consumer.

- Match the Chemistry: Always align your LED peak with the photoinitiators found in your ink's TDS.

- Consider Penetration: Use longer wavelengths (395 nm) for high-pigment or thick-film applications.

- Verify Surface Finish: Shorter wavelengths (365 nm) are often superior for scratch-resistant coatings.

- Test and Validate: Use physical adhesion and rub tests to confirm cure integrity rather than visual inspection.

How Do Photoinitiators in UV Inks Respond to Different Wavelengths?

How do photoinitiators used in UV inks respond to different UV LED wavelengths? Each photoinitiator has a unique spectral absorption curve. When the LED wavelength matches the peak of this curve, the initiator absorbs the maximum energy, splitting into free radicals that trigger the rapid polymerization of the ink's resins.

How Does Ink Thickness Influence Wavelength Selection?

How does ink film thickness affect the choice of UV LED wavelength? Thicker ink deposits, common in screen printing or heavy inkjet laydowns, require longer wavelengths like 395 nm or 405 nm. These wavelengths can travel deeper into the material before being absorbed, ensuring the base of the film cures as effectively as the surface.

How Does Substrate Type Affect UV Ink Wavelength Choice?

How do different substrates influence UV ink curing and wavelength requirements? Porous substrates like paper may absorb some ink, requiring deeper penetration to ensure the embedded resin solidifies. Non-porous films may block certain UV ranges, necessitating a wavelength that can pass through the material if curing from the reverse side is required.

How Do Cure Speed and Production Rate Interact With Wavelength?

How do production speed requirements influence the optimal UV LED wavelength for ink curing? At high production rates, the "dwell time" under the lamp is minimal. A wavelength that is perfectly matched to the ink's chemistry delivers the required energy dose ($J/cm^2$) more efficiently, allowing you to increase line speeds without risking under-cured output.

What Are Common Signs of Incorrect Wavelength Selection in UV Ink Curing?

What signs indicate that the UV LED wavelength may not be properly matched to the ink? Common symptoms include "ink migration" through packaging, poor solvent resistance, or a failure of the ink to bond to the substrate (adhesion failure). You might also notice a "tacky" surface or inconsistent gloss levels across the print web.

Final Thoughts

Finalizing your wavelength selection is the ultimate step in securing the long-term reliability of your printing process. While it is tempting to view UV LEDs as a "one-size-fits-all" solution, the technical reality is that the spectral output of your lamp dictates the physical limits of your production line. By matching the irradiance and wavelength of your system to the specific pigments and photoinitiators of your ink, you create a robust manufacturing window. This data-driven approach ensures that your colors stay vibrant, your bonds stay permanent, and your press stays running at peak efficiency.