What is meant by Coating Cure Process?

- Basically, coating curing involves the conversion of a liquid or semi-liquid coating to a solid protective coating based on physical and chemical changes. Solidification of the coating occurs by the following processes: solvent evaporation, polymer cross-linkage, and the curing of resin that stabilizes the molecular structure of the coating.

- Curing is also a permanent chemical bond formed in the coating, which is unlike simple drying that involves solvent evaporation. This is the reason why air drying and curing coatings are a significant difference in the industrial setting. Air-dried coating can be touched and seems to be dry, yet it cannot develop coating hardness, as well as its durability will be limited.

How Does Coating Curing Work?

Coating mechanisms rely upon the chemistry of the material, the amount of energy, and the control of the process. Polymer chains react, cross-link, and become stable when curing starts. This polymerization process has a direct influence on the performance of cured coating, the strength of coating adhesion, and resistance to abrasion or chemicals.

The process of curing normally includes:

- Activation by heat or radiation.

- Regulated heat of curing and hold period.

- Brings a homogeneous energy supply.

- Solidification of molecular structure.

This is a balance to guarantee the cure of the coating free of defects and the avoidance of under-curing or over-curing of the coating.

Industrial Significant Coating Cure Processes

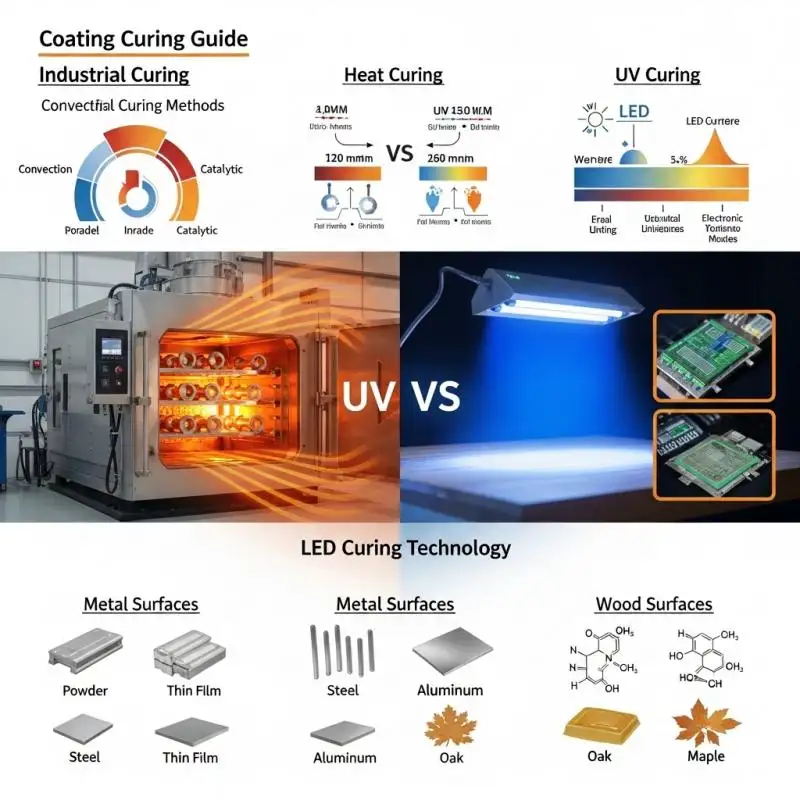

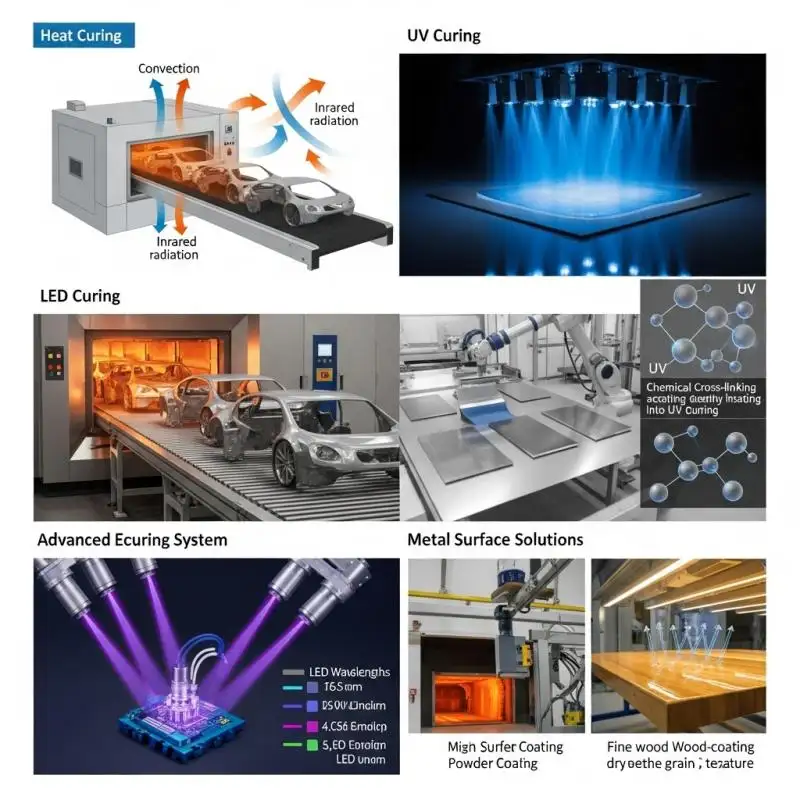

- Coatings, Thermal Curing and Heat Curing Coatings

Heat-curing coats are based on the thermal energy under control to activate resin curing reactions. Such systems are widely applicable in powder coating the curing and epoxy coating the curing, particularly on metal substrates.

Common temperatures during curing:

- Temperature: 120degC to 220degC

- Cure time: 10 to 45 minutes

- Systems: Convection curing ovens, infrared curing technology, and hybrid technology.

Heat curing guarantees deep curing of polymerization and strong adhesion strength of the coating, but it usually consumes more energy.

Radiation Curing Coatings and UV Coating Curing Coats

The curing of UV coating involves the use of ultraviolet radiation to initiate instant curing of polymer cross-linking without generating excess heat. It is used more in the rapid curing of coating solutions in electronic, medical device manufacturing, and packaging coating curing.

Radiation curing has the benefits of:

- Quick drying (seconds and not minutes)

- Low thermal stress

- Very high quality of surface finish.

- Better process consistency control.

Present-day UV curing systems contain UV mercury lamps, infrared hybrids, and LED curing of coatings.

LED Light Curing Technology

LED curing technology is one of the significant advances in the curing of coatings in industries. LED curing devices generate narrow wavelengths, which are stable with instant on/off control, so they provide accurate curing kinetics with less energy consumption.

As compared to the conventional UV lamps:

- No warm-up time

- Much longer life expectancy.

- Lower heat output

- Curing systems that consume less energy.

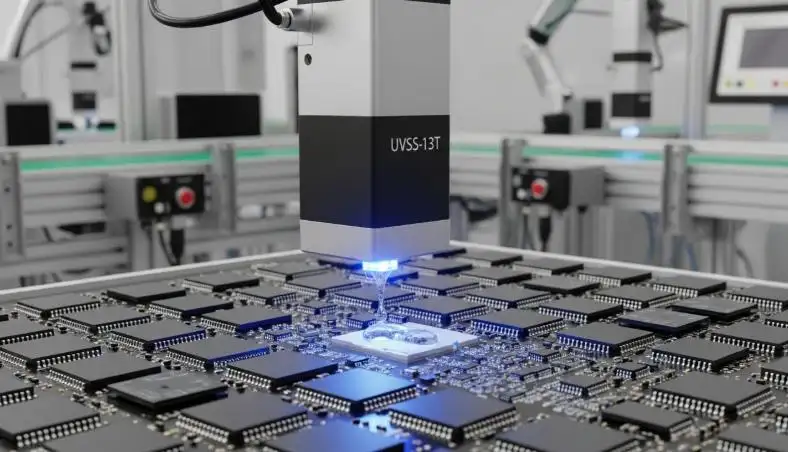

Highlight: UV LED Curing Light- UVSS-390V6

- The UV LED Curing Light (Model: UVSS-390 V6) is a powerful product that can suit the needs of manufacturers interested in precision, reliability, and scalability, which is a perfect exposure to meet the requirements of modern coating curing.

- This system has a 90 x 90 mm irradiation area, and the system is ideal for providing uniform curing in large surface areas. Water cooling gives maintenance to the performance and stability of the performance over long operation when the process is required to achieve the curing cycle optimization in mass production.

- This makes manufacturers capable of adjusting the curing wavelengths to the resin absorption properties, leading to higher coating cure levels and dependable cured film depth.

Why the LED Curing Is Changing Industrial Coating Curing?

The UV LED curing light is unique in that it provides high energy density in addition to being thermally stable. This combination provides control in the uniformity of the curing process, even in heat-sensitive components.

The industries that would be the greatest beneficiaries include:

- Electronics curing

- Curing of medical equipment coating.

- Optical bonding

- Optoelectronics manufacturing

LED systems enable even curing of coating, adhesives, and resins, without blistering after curing or coating cracking during the cure.

Curing Coating on Metal, Plastic, and Wood Surfaces

- Metal Substrate Coating Cure

Metal surfaces will need powerful curing to resist the damage of corrosion, abrasion, and mechanical forces. The prevailing methods in this space are powder curing and epoxy curing, which are assisted by thermal curing technology and infrared curing.

- Plastic Coating Curing

Plastics also have the advantage of UV radiation curing and light curing of LEDs because of their low thermal tolerance. This is the way to guarantee the coating adhesion without deformation.

- Wood Coating Finishing

In wood coating curing processes application the UV LED curing enhances a good texture on surfaces without distorting the natural texture.

Paint Coating Curing Time: What Does It Depend on?

The time of curing of paint depends on:

- Resin chemistry

- Curing temperature control

- Solvent evaporation rate

- Film thickness

- Energy source

UV and LED systems save curing time by several factors, such as hours to a few seconds, which means that throughput is enhanced and higher costs of doing business are minimized.

Compliance Requirements and Industrial Applications

- Automotive Coating Curing

- Needs wear-resistant finishes and uniform thickness of cured films.

- Aerospace Curing Standards.

- Require extreme control of process and post-curing chemical resistance.

- Medical and Electronic Industries.

- Demand defect-free coating cure and clean low-temperature curing conditions.

The standards of coating curing and industrial coating specifications guarantee the safety of a product and its durability.

Selection of the Optimum Curing System on Industrial Coatings

The most effective way of curing industrial coating lies in:

- Substrate material

- Demands for the speed of production.

- Energy constraints

- Coating chemistry

Hybrid curing technology usually uses a combination of thermal and UV processes to achieve maximum efficiency and as well as reduce defects as much as possible.

Conclusion

Curing Coating is the area of the interface of chemistry and engineering, and the real definition of performance. Since cross-linking of polymers and creating films are the steps of making the products, as well as coating the surfaces so that they resist the harsh conditions, curing is the pulse of modern manufacturing. With the adoption of the new LED curing technologies, the control of the processes, and the use of the energy-saving systems, the industries will get a high level of durability of coating, the reduction of the production cycle, and long-term quality assurance. Visit UVET for details.