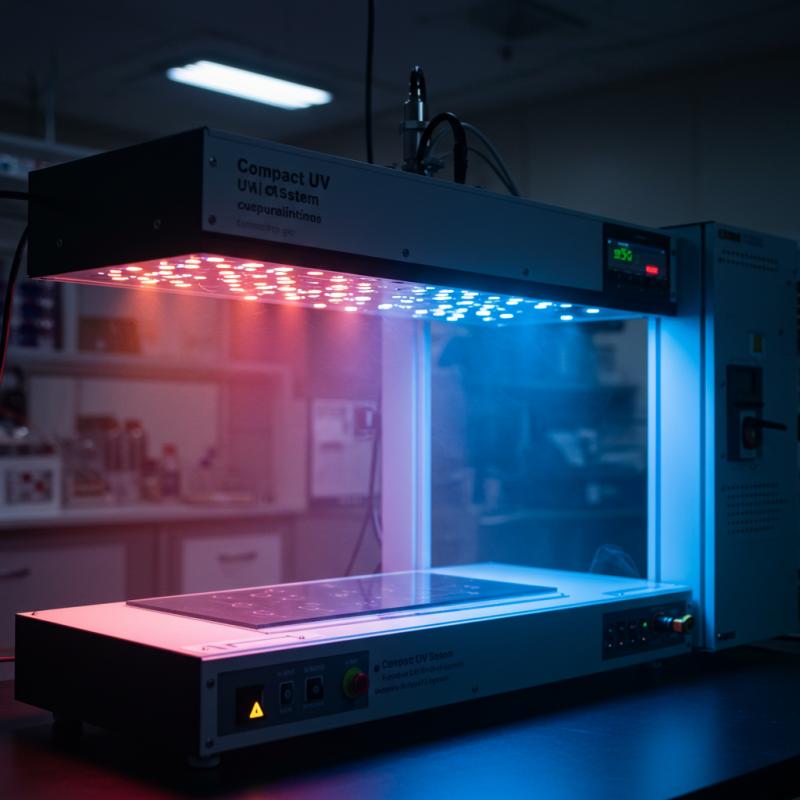

What is a Compact UV System?

- A Compact UV System is a compact and transportable alternative to ultraviolet curing of adhesives, polymers, resins, and other UV-susceptible finishes. Compared to conventional bulky UV curing systems, the systems are compact, energy efficient, provide non-thermal curing, and find use in labs, for industrial and field repair operations. Such systems utilize the technology of UV LED to attain the high rates of curing, spot polymerization, then the performance outcome in a small physical space.

- Electronics assembly, dental and medical uses, even jewelry and craft manufacturing industries are turning more and more to UV systems to cure faster, safer, and more environmentally friendly UV.

The functionality of Compact UV Systems

- UV LED Curing Technology

A compact UV system involves the use of UV LED sources, which emit wavelengths (365 and 405 nm are typical), and are then used to trigger photo polymerization of an adhesive or resin. Such an immediate effect turns the liquid components into concrete and long-lasting layers within a span of seconds, without using heat.

- Non-Thermal Advantages

UV LED curing is low-heat compared to mercury lamps. This avoids deformation of the substrate and so is ideal for heat-sensitive materials, such as PVC, PET, foils, paper, and delicate electronic parts that are delicate.

- The intensity and wavelengths are adjustable.

The recent illumination systems with UV compacts are programmed to change wavelength and light intensity levels so that the curing may be adjusted to the requirements of different materials and thicknesses. This malleability provides very good adhesion, reproducibility, and minimized production line stoppage.

Applications of Small-Scale UV Systems

- Adhesive and Polymer Curing

UV systems are highly applied in the curing of adhesives and polymers with precision. These systems can do instant photo polymerization with electronics components, specialty resins, and dental materials, making them very strong and durable without causing damage due to heat. They can fit in small spaces to cure those sections, thus offering specific treatment on those spaces that may be sensitive.

- Electronics Assembly

UV systems also supply spot curing of PCBs, micro-assemblies, and LED bonding in electronics assembly. UV LED curing takes very little time, therefore cutting down on downtime and eliminating thermal stress on sensitive components. The adhesion and performance are maintained through high-intensity compact systems.

- Dental and Medical Usage

These systems provide safe and efficient curing of such sensitive dental and medical materials as composites, surgical adhesives, and more. The non-thermal curing technique preserves the sensitivity of biological or heat-sensitive substrates, combined with high precision of curing.

- Jewelry and Craft Making

UV systems are perfect against resin casting, coating, as well as decorative craft works. Instant curing means less mess, more efficiency, and it enables artisans and manufacturers to complete high-quality finishes with less time.

- On-Site Use/ Field Repairs

On-site portable UV systems facilitate plastics, coatings, and adhesives. They are wireless and lightweight, thus flexible and efficient, and are indispensable to field technicians and maintenance crews.

Benefits of UVs

- Rapid Curing

The UV systems allow immediate curing of adhesives and resins to cause strong bonds in a few seconds. This dramatically cuts production and repair times, which is more efficient.

- Energy-Efficient

UV systems with LEDs use very little power as opposed to the conventional mercury lamps. This renders them environmentally friendly and affordable both in the laboratory and the industry.

- Non-Thermal Operation

The non-thermal curing machinery ensures that the heat-sensitive materials like plastics, polymers, and fragile electronic materials are not ruined during curing.

- Portable and Flexible

The small size, coupled with the lightweight and cordless construction of UV systems, is suitable for repairs in the field or lab work, or low-level production. They are quite bendable, resulting in specific curing of tight or delicate spots.

- High Precision

UV LED curing is spot-focused, which guarantees precise positioning on adhesives, resins, and coatings, and will improve quality and waste.

- Hardy and Permanent

The systems also have a longer life (over 20,000 hours on LEDs) with minimal maintenance, hence this reduces costs as they perform well over the years.

Benefits of performance and productivity

- Uniform Adhesion: Stable and firm adhesions with each use.

- Reduced Downtime: Instant curing speeds up the workflow.

- Energy Compilations: Low power usage as opposed to conventional lamps.

- Multi-purpose: It can be used with adhesives, resins, coatings, and polymers.

Equipment & Tools of Compact UV Systems

- Portable Compact UV Devices: On-demand curing within compact or remote applications.

- Mini UV LED Systems: Large-scale production with industrial-level curing that covers small-scale.

- Modular UV Units: Labs and Factories Retrofit.

- Safety Accessories: UV exposure protective goggles and shields.

What are the Reasons behind a Compact UV System?

The move towards a Compact UV System means that production is faster as well as precise, energy use, and safe. Using the right combination of technology, portability, and reliability, these systems work perfectly in field operations, labs, or industrial premises. Specifically, adhesives, polymers, and specialty resins can include manufacturers and technicians in attaining uniformity, minimizing loss of time, and constant production of high-quality outputs.

Conclusion

Compact UV System offers new ideas about efficient, portable, and precise UV curing. This technology uses energy-saving LED lights, non-thermal curing, and high-speed polymerization, which makes its use suitable for industries, laboratories, and on-site use. Its systems are highly productive, cost-effective, and reproducible because they are designed modularly, are easily transported, and maintainable. In companies that have the need to obtain higher levels of scalability and eco-friendliness, as well as use UV curing devices, small UV systems add the promise of efficient material processing in the future. For more details, visit UVET.