The Ultimate Guide to High-Performance, Precision UV Lighting Solutions

The Custom UV LED technology is one of the foundation blocks of the present-day fast-changing industrialized world, where precision, energy conservation, and durability are required in applications. With the highly sophisticated production and the more delicate medical practice, the industries are now turning confidently to the customized UV LED lighting with the desire to have a solution that is flexible and has a better optical production, coupled with a sense of precision that conventional lamps cannot provide.

The increased use of Ultraviolet LED technology in electronics, optics, printing, coating, curing, and scientific laboratories is an indication that industries are shifting towards cleaner, more stable, mercury-free free and energy efficient. There has been an exponentially increasing demand for custom design of UV LED, UV LED engineering, optimization of UV LED technology, and custom wavelength of UV LED modules. The move is indicative of a need to have lighting solutions that will not only provide precision but also enhance the workflow and consistency to a great level.

Technical Foundation: Learning of UV Wavelength Choices and Performance

An effective Custom UV LED solution will combine a number of technical components, such as selection of wavelength, optical engineering, thermal control, and LED packaging. We will discuss the most widespread wavelengths:

365nm UV LED

Deep-curing, bonding, precision adhesive work, forensic inspection, and micro-electronics.

385nm UV LED

Balanced wavelength that is often employed in coating, printing, and industrial curing.

395nm UV LED

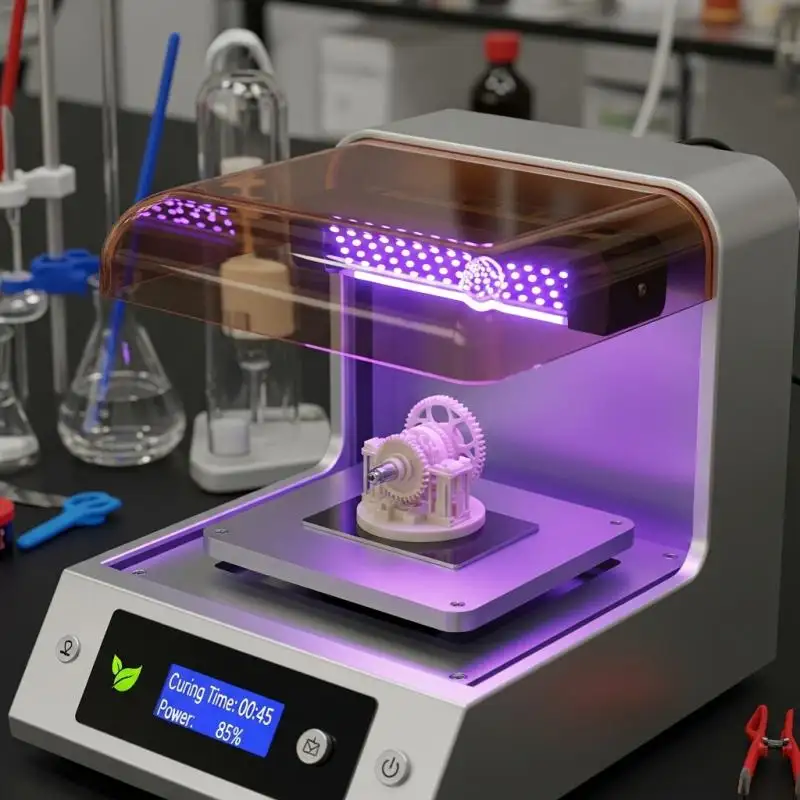

Common in resin curing, 3D printing processes, and the overall manufacturing processes.

405nm UV LED

Appropriate for surface curing, fluorescent testing, coating, and use of low heat output.

All these wavelength choices enable engineers to construct personal UV LED modules with precise requirements. Moreover, UV irradiance, UV LED power efficiency, UV LED heat dissipation, UV module design, and UV lens and optics design are the factors that affected performance considerably. These components, when designed correctly, provide stable output and prolonged efficiency.

Custom UV LED Modules: Precision Applications

To ensure that the module is of the best performance, a Custom UV LED module is assembled according to the requirements. These modules include:

- Customized wavelengths

- Optical lenses & reflectors

- Thermal stability heat sinks.

- The intensive UV diode arrays.

- Designs of PCBs in the present-day regulation.

- Encapsulation and packaging of UV LEDs.

- Individualized beam shapes (focused, narrow, wide)

OEM UV LED manufacturing, custom LED module manufacturing, UV LED assembly, and UV LED product development are key to businesses that need to develop systems that are indeed precision-engineered.

Custom UV LED Systems in Industry

Our systems are used in industries throughout the world as they provide superior control and performance. The significant areas of application are:

Special UV LED to Print and Coat

UV LED is the ideal solution to ink curing, varnishing, and finishing because of its fast curing rates, consistent production, and flexibility in wavelengths.

UV LED Custom Laboratory Equipment

Applied in fluorescence detection, UV exposure, resin testing, and microbial studies.

UV LED to check the Inspection and Counterfeit.

UV LEDs showcase unseen features, marks, and patterns that would otherwise not be seen in total light.

UV Industrial Curing and manufacturing of LED.

Ideal for adhesive curing, PCB exposure, optical bonding, as well as polymer hardening.

Medical devices and sterilization UV LED

It is used to disinfect as well as to sanitize tools as well and to produce delicate medical parts.

Water and air purification UV LED

UV systems that can be controlled in wavelengths disable unpleasant microorganisms without the use of chemicals.

Future of Fast, Focused, High-Performance UV Curing

The UV LED Spot Curing System is one of the most developed technologies in UV curing, which is today a small but powerful innovation that is aimed at performance, speed, and industrial reliability.

It is a high-intensity system that is designed to cure quickly and precisely in high production, and thus a very good solution to UV-sensitive adhesives, coatings, potting materials, and encapsulants. Having a maximum of 14W/cm2 UV, it provides significant power or energy to the location where it is required, and this significantly minimizes the curing time and enhances efficiency.

Wavelength Flexibility

The system facilitates the entire range of curing wavelengths:

365nm, 385nm, 395nm, and 405nm so that it is compatible with a variety of materials and processes. This flexibility is an improvement in performance in applications such as:

- Electronics assembly

- Medical device bonding

- Optical component sealing

- Adhesive curing

- Resin hardening

- Modular, Compact Design

Its small and compact design is easily integrated into benchtop stations and automated industrial lines. In electronics, optics, or medical manufacturing, this system will be seamlessly integrated into current working processes.

User-Friendly Interface

Operators are content with intuitive controls, which provide:

- Simple setup

- Smooth operation

- The training needs are minimal.

- Performance Features

- Intense UV to cure quickly.

- Consistent production over a long production run.

- Curing is dependable and consistent.

- Industrial and scientific applications.

Eco-Friendly & Efficient

The system does not produce a lot of heat, uses less energy, and does not release mercury, which makes it safe to both the operators and the environment.

Built for Industrial Needs

It is designed to operate in harsh conditions and provides:

- Fast throughput

- Instant start (no warm-up time)

- Low maintenance

- Long LED lifespan

- Easy connectivity with automation systems.

The UV LED Spot Curing System is indeed the next generation of UV curing, that is, it is a combination of accuracy, high UV intensity, and high-level engineering to sustain high performance in industries.

Why Custom UV LED Systems are better than Traditional UV Lamps in Use by Industry?

Replacement of mercury lamps by the Custom UV LED systems is fast gaining momentum because of the numerous benefits, which include:

Long Lifespan

LEDs have lifespans of tens of thousands of hours, so there are no frequent replacements of the bulb.

On-Off Instantaneity

No warm-up time-improves throughput and efficiency.

Energy Efficiency

Increased UV output at much reduced energy consumption.

Low Heat Emission

- Protects material against thermal damage.

- Eco-Friendly Operation

- No mercury, environmentally friendly, and safe.

- Accurate Wavelength Selectivity.

- Enables optimum curing capability and minimum wastage.

That is the reason why industries are turning to the use of highly developed UV illumination systems, professional UV LED equipment, custom-designed ultraviolet lighting systems, and industrial UV LED systems, which provide clean and effective curing.

Selecting the Optimum Custom UV LED Solution to Use in Your Application

The following features should be considered when choosing a LED solution:

- Required wavelength (365-405nm)

- Strengths and radiance measures.

- Optical requirements: Beam size

- Thermal management

- Module dimensions

- Integration with the existing machines.

Environmental requirements

An effective custom UV design incorporating UV LED thermal control, UV diode design, and efficient optical design will never fail to work better and last longer.

Conclusion

Custom UV LED technology is a reliable, sustainable, and very efficient technology in performing precision jobs as the industries transform. Our UV LED modules, custom UV LED lamps, customized UV illumination, or full-fleet custom UV LED systems: The flexibility and design of these options deliver performance unmatched by the competition.

Our solutions can offer industries durability, efficiency, and next-generation performance without any uncertainty that the companies will remain at the forefront in the competitive market.