The Comprehension of the Enclosed Curing System

A closed curing system will be used to protect from UV light, exposure and provide a uniform curing atmosphere. These systems combine high-end UV LED curing technology into an enclosed curing chamber with the benefit of offering an operator exceptionally high safety, coupled with a constant level of curing intensity and an exceptionally high level of precision manufacturing.

With enclosed units, unlike open UV curing systems, there is insulation of UV-safe environments and exposure is minimized, as well as thermal stability is improved during operation. It is especially critical in the context of such industries as electronics, medical devices, and coatings, where photoinitiator activation and polymer crosslinking reactions have to be accurate in order to create the maximum possible product performance.

The Notable Characteristics of Enclosed Curing System

The success of an enclosed photopolymer curing system lies in the design and technical characteristics. New units are being integrated with innovations that are more efficient in terms of performance, energy use, and safety. The following are the most significant features:

High-Power LED UV Modules

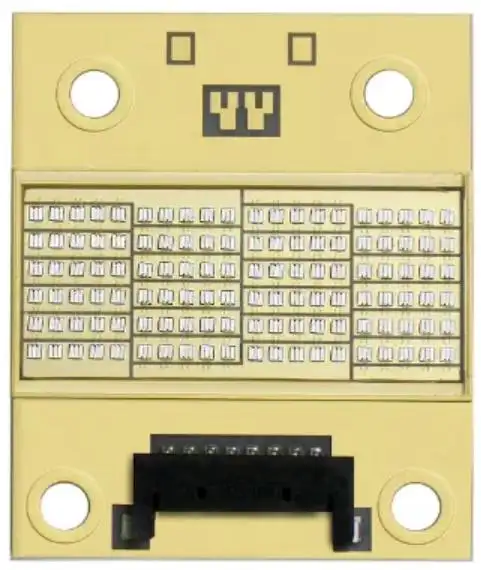

Numerous confined curing systems, such as the COB LED UV Solution, use high-power UV LEDs on one metal core printed circuit board (MCPCB). The 120 Chip COB LED UV Solution 40X33.2mm has the following features:

- 120 high-power LED chips to provide uniform, high-intensity UV.

- Advanced thermal control is required in order to have stable, long-term performance.

- Small, space-saving design that can be used in industries and hospitals.

This LED array curing system is ideal for electronics curing, adhesive curing, and optical bonding because it has a higher photoinitiator activation and polymer crosslinking due to its high precision in wavelength control (365nm / 385nm / 395nm / 405nm).

Controlled Curing Environment

A precision curing system is based on the regulation of a UV exposure environment. The temperature, light intensity, and curing time should be properly controlled. Enclosed units provide:

- Auto-thermal-sensitive materials, Therma-curing.

- Even distribution of light to avoid curing irregularities or flaws.

- UV shielding curing machine to shield operators from harmful exposure.

The enclosed design will lead to a dust-free curing environment and minimize the chances of contamination, and improve product consistency.

Small, Power-Saving Construction

An acknowledged curing system is based on Chip-on-Board (COB) LED technology, where many high-power LEDs are embedded on one substrate in a modern LED enclosed curing system. The benefits include:

- Less area is taken by the system with no loss of intensity.

- Reduced operational expenses because of energy-efficient LEDs.

- Long service of 20,000-30,000+ hours.

This small-sized curing system is ideal for industries that have space limitations or automated production lines that require enclosed automation systems.

Large Curing Accuracy and Reliability

In applications such as medical equipment, UV curing, fiber-optic, or PCB varnish curing, precision is important. High-intensity curing enclosures are sure to give:

- Balance in the intensity of curing over the surface.

- Rapid drying period to enhance manufacturing speed.

- Reduced maintenance needs because of constant thermal control.

These systems are a good option when a high level of consistency is required and when very few errors in the final product are allowed.

Technical Knowledge: The COB LED UV Solution

The unique innovations of the contemporary enclosed curing system are one of the most innovative and outstanding products, the COB LED UV Solution, meant to address the high demands of both industrial and medical usage.

Key Specifications

Strong UV Intensity: Intensive, homogenous UV emission speeds up the procedure of sterilization and curing.

Chip-on-Board Design: The chip-on-board design uses numerous UV LED chips on one MCPCB to save space.

Better Thermal Dissipation: State-of-the-art thermal management ensures the absence of overheating and steady workload.

Long Service Life: Design and Build is durable and therefore can work 20,000-30,000+ hours.

Mercury-Free and Energy-Saving: Uses less energy than conventional UV lamps and matches the ecological requirements.

Advantages

Improved Reliability: Thermal management is stable, and this means minimal downtimes.

Accelerated Production Effectiveness: The level of UV intensity reduces the time taken to cure and sterilize.

Reduced Operating Costs: less electricity and maintenance charges.

Eco-Friendly: Mercury-free UV solution is globally sustainable.

Stable Quality Deliverables: UV is good and stable; this guarantees consistency of adhesives, coatings, and sterilization.

COB LED UV Solutions will give you the desired combination of strength, longevity, and environmental friendliness, whether in industrial curing box applications, resin 3D printing post-curing, or optical adhesive curing.

Applications

Enclosed UV curing units are common to various industries, which are:

Electronics and PCB Manufacturing

Precision PCB UV curing enclosures are used to guarantee quick curing of solder masks, varnishes, and coatings. Microelectronics production lines have higher efficiency since they control UV exposure to prevent warping or defects.

Adhesive Bonding in the Industry

Solutions that are enclosed and light-curing are needed in bonding plastics, metals, and composites. The intense level of UV production compensates high curing speed of adhesives with thermal stability.

Optical Component Assembly

With optical components, it allows reliable curing to eliminate misalignment and provide any precision curing role. It is used as lenses, fiber optics, and transparent adhesives.

Sterilization of Medical Devices

Medical equipment is sterilized in enclosed UV curing systems that minimize the risk of microbial contamination and control the UV environment.

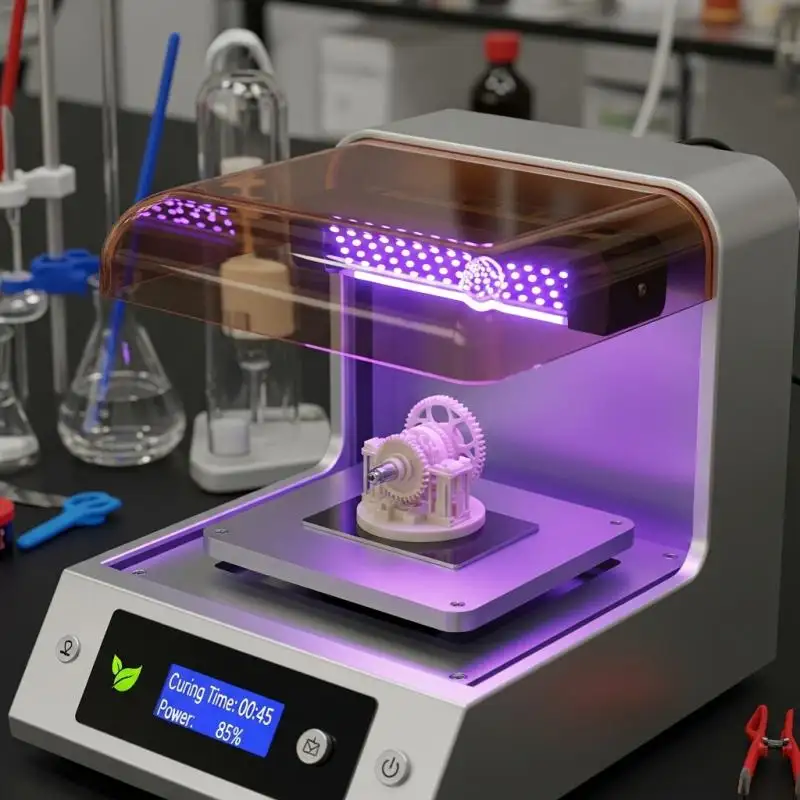

Resin Post-Curing and 3D printing

UV resin curing chambers enhance the mechanical characteristics and accuracy in dimensions of the 3D-printed parts. UV curing chambers with an accurate output of wavelength guarantee total polymerization.

Coatings and Printing Applications

Enclosed UV systems are used in printing and coating curing to bring about uniform curing of inks, varnishes, and coatings to produce a more stable and better outlook.

Why is an Enclosed Curing System preferable?

The advantages of investing in an enclosed curing system with high quality include:

Operator Safety: UV-shielded enclosures minimize exposure to harmful things.

High Efficiency: Rapid, even curing saves time in production.

Improved Stability: Light is consistent and stable, allowing minimal downtime.

Cost Savings: LED modules are energy efficient and save on electricity spent, and reduce maintenance.

Eco-Friendly Operation: Low-power consumption LEDs are mercury-free.

For businesses that require solutions to industrial curing systems, custom UV curing chambers, and high-performance enclosed curing system, there is no better unit with value and long-term performance than these units.

Selecting the Ideal System

At the time of choosing an enclosed curing unit in industry, he/she must take into consideration:

Wavelength Requirements: Check the UV wavelength (365nm / 385nm / 395nm / 405nm) of your material photoinitiator requirements.

Size of System: Select either a small size curing system when space is a reason or a completely sealed curing room when large production volumes are needed.

LED Power/Intensity: High-power LED modules guarantee rapid, even curing.

Thermal Management: High-tech heat dissipation aids in avoiding material damage and increasing the system's life.

Automation Integration: Enclosed automation systems are more efficient in high throughputs.

Conclusion

The closed curing system is a breakthrough in the industrial and medical UV applications, which integrates UV LED technology in curing, curing accuracy, and low power usage. The systems have high accuracy in curing and have superior reliability and are more efficient in terms of production, with characteristics such as COB LED UV modules, thermal management, compact, and fully enclosed chambers.

Discover the enclosed curing solutions of UVET that combine the best in terms of power, durability, and environmental friendliness, and make it the solution of choice among other industries across the globe.