What is Curing Energy Efficiency?

- Energy-efficient curing is a technique of curing or polymerizing materials with the use of light sources that saves energy and, at the same time, does not affect high performance. Low-energy curing technology takes advantage of UV LED energy-saving curing in place of conventional UV curing systems, but uses mercury lamps and generates a lot of heat that increases thermal effect, unlike low-energy UV curing technology that provides controlled UV light exposure, precise photo polymerization, and minimized thermal effect.

- Controlled-energy curing process will guarantee uniform curing behaviors of all materials used in the process, including adhesives, coatings, inks, and resins. Having even light distribution, maximum exposure time, and repeatability, the manufacturers may obtain precision energy-efficient curing without affecting the speed and quality of production.

Benefits of the Energy-Efficient Curing Technology

The advantages of energy-saving curing systems are not limited to energy savings, but can be seen in real terms of better efficiency in the functioning of the systems and improved reliability of the products. Key advantages include:

- Rapid and Low-Heat Curing

Low-heat curing is a technique that enables the working of temperature-sensitive components to take place without heat exposure. This proves to be particularly useful in electronics assembly, medical devices, and optics production. Quick curing consumes less energy and, in turn, quickens the production cycles and therefore throughput and improves operations.

- Uninterrupted and Dependable Performance

Energy-efficient curing includes a controlled thermal output and optimized curing parameters, which guarantee consistency in cure performance within batches, improving the quality of the products and minimizing waste. High repeatability curing reduces defects and aids production lines that are automated.

- Green and Environmental Safety

The use of eco-friendly curing systems and mercury-free energy-saving curing solutions helps in the low-carbon footprint curing technology. The advantages of sustainable industrial curing processes are extended to the manufacturers to minimize the energy use, minimize the cost of operation, and comply with the regulatory standards like RoHS.

- Precision and Flexibility

Curing accuracy enables manufacturers to direct the intense UV emission in selective locations and shield the neighboring components. Systems like the LED curing modules energy saving and the UV LED arrays energy energy-saving curing, supply flexibility to a wide range of industrial applications.

Application of energy-saving curing in industries

The application of energy-efficient technology in curing has been widely used in various industries. Its capacity to provide a quick, trusted, and accurate curing process makes it a critical instrument in the contemporary production industry.

- Adhesives Curing Energy Efficiency

Curing adhesive bonding entails instant and consistent UV exposure to provide secure and consistent adhesion. A common application of energy-efficient curing of adhesives is electronics, optical, and medical device assembly, where the ability to precisely cure adhesives enhances the structural integrity without heating components.

- Coating and Ink Energy-Saving Curing

Energy-efficient curing of finishes is used in surface coating, UV-reactive inks, and in the process of coatings that provide smooth and durable finishes at minimal energy usage. On the same note, the use of ink in industrial printing is perfect because it is cured using the energy-saving technique, which improves the speed of printing and the quality of colors.

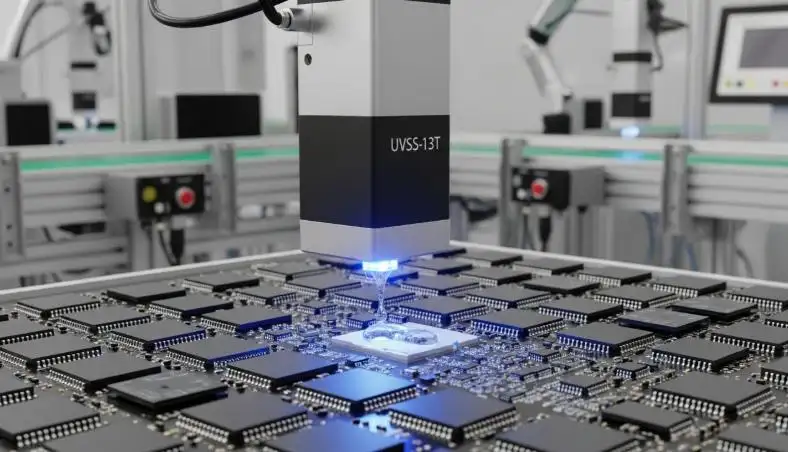

- Electronic and Medical device curing Energy-saving

The use of energy-efficient electronics curing in manufacturing allows curing of conformal coatings, encapsulants, and micro-assemblies within a short amount of time, resulting in consistent production and safeguarding delicate components. The technology is utilized in medical equipment in bonding catheters, diagnostic cases, and other essential components to offer sustainable curing solutions with reduced heat effects.

- Printing Curing using less energy

Within the industrial printing sector, printing takes advantage of energy saving through current curing to enhance the UV exposure of inks and coatings, enhancing adhesion, speed of drying, and print quality, and lowering the total energy consumption.

Technical Insights into Curing that is energy efficient

The efficiency of the energy-efficient curing systems is based on a number of technical parameters. The knowledge of these factors will enable manufacturers to streamline processes to be fast, precise, and sustainable.

- LED Curing Energy Effectiveness

LED curing energy efficiency has ensured that the light output is adjusted specifically to the absorption spectrum of the material. LEDs are used in curing systems and low-energy curing technology to support the production of high-intensity UV light at minimal wasted energy consumption, unlike mercury lamps with a hot spot.

- Maximum Exposure and Even Light Disbursement

Manufacturers can ensure uniform curing on complicated surfaces by controlling UV irradiance and exposure time and evenly distributing light. The controlled-energy curing processes also eliminate excessive exposure and material losses, hence leading to high-quality products.

- Thermal Management

The sophisticated water-cooled curing systems have low operating temperatures of long operation, which safeguard the heat-sensitive parts and minimize maintenance needs.

UV LED Curing Pen - Model NSP1

The UV LED Curing Pen, Model NSP1 by UVET, is one of the innovative solutions that will be used in energy-efficient curing. This is a portable UV LED curing pen, which is precise and requires low energy to be used on the road.

Most important Features and Specifications.

- UV Spot Size: Ph4mm, Ph6mm, Ph8mm, Ph10mm, Ph12mm, Ph15mm.

- UV Wavelengths: 365nm, 385nm, 395nm, 405nm

- Power Supply: Rechargeable Li-ion Battery.

- Weight: 130g (with battery)

- Instant On/Off: No warming up is needed.

- Six exchangeable optical lenses in either spot or wide-area curing.

Applications

The UV LED Curing Pen NSP1 can be used in:

- Adhesives Curing, Energy-saving treatment in electronics and medical devices.

- Spot curing of the UV-active finishes.

- Optical and small-component assembly of precision repair.

Its cordless design and low-heat production are an assurance of mobility and safe operation in sensitive settings, even at the same time as a low UV production and predictable curing effect.

What is the Reason to use Curing Technology that will consume less energy?

Energy-saving systems have been able to provide a combination of speed, precision, sustainability, and cost-saving qualities that the traditional systems are unable to equal. The major reasons why this technology should be adopted are:

- Lower operational expenses through energy-saving curing.

- Better quality of products and energy conservation.

- Reduced power curing for faster production cycles.

- Additional process control using energy-consuming systems.

- Free-flowing curing devices of long service life.

Through the incorporation of industrial energy-efficient curing into production lines, businesses are able to optimize energy consumption in the curing process, lessening downtime and having a consistent outcome.

Conclusion

The use of energy curing is a radically new approach to manufacturing in industry. It will meet the increased needs of contemporary production by incorporating accuracy, rapidity, and sustainability, and minimizing environmental effects. With green, energy-saving LED curing modules in addition to some of the newest products, such as the UV LED Curing Pen NSP1, manufacturers now have options of green, fast, and high-performing curing technologies that provide a consistent outcome in a variety of applications. To learn more about the professional energy-efficient curing solutions, visit UVET.