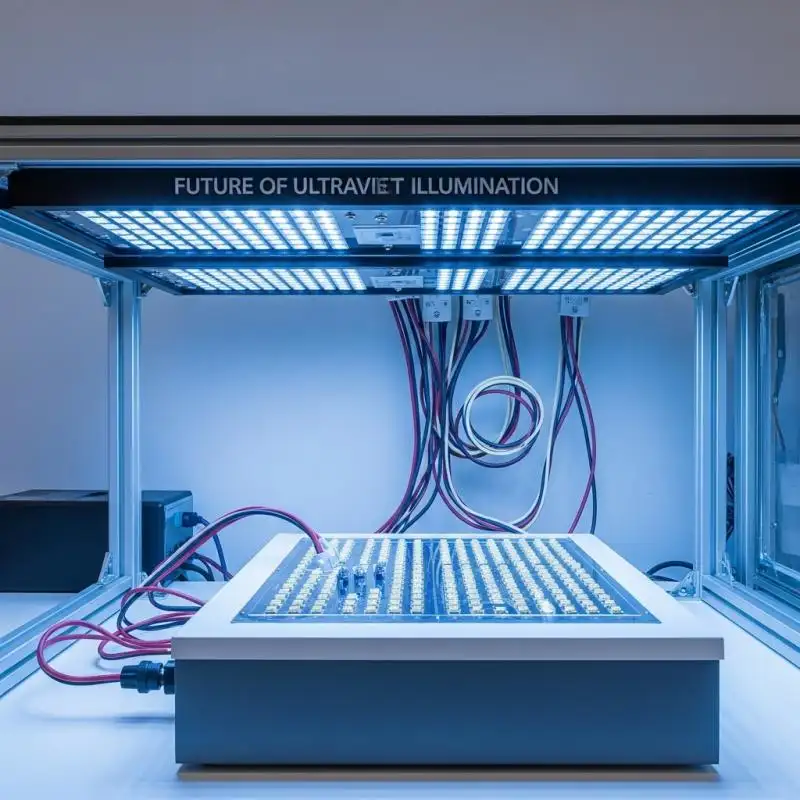

The flat-panel UV LED Technology

The future of the ultraviolet illumination is flat-panel UV LED technology. These systems provide uniform and high-intensity UV light over an extended UV wavelength lighting spectrum by incorporating ultraviolet light-emitting diode modules and accurate photonics engineering of LEDs. As opposed to the old-fashioned mercury lamps, the lamp offers quick start-up, uniform output, and uses less energy by generating UV light, successful in high-volume industrial processes as well as the sensitive laboratory conditions.

The fundamental features of the UV LED systems are:

Excessive UV light: Secures effective curing and dependable outcomes.

Narrow-band UV spectrum: Supporters of certain photopolymerization events.

Even distribution of irradiation: Eliminates hot spots and guarantees quality uniformity.

UV LEDs thermo management: Maximum performance and heat dissipation.

The characteristics of its operation are that flat-panel UV LED units are essential to the fields of operation where precision, reliability, and energy efficiency are very important.

Uses

A highly attractive feature of UV LED flat panels is their versatility. Electronics and other medical equipment industry applications are dependent on these systems to provide accurate, fast, and consistent curing. Key applications include:

Electronics Manufacturing and PCB Exposure

UV LED flat panel PCB exposure in electronics manufacturing. In electronics manufacturing, printed circuit boards can be transferred onto a PCB with accuracy using a UV LED flat panel. Surface-mount UV LED panels are used to assure uniform UV exposure, eliminate defects, and enhance the yield of production.

Printing Applications

This UV LED panel lights find application in printing and graphic applications. Flat panel UV lights enable quick curing of inks, coated, and adhesives using photopolymer, which improves the quality of the print and speed of production.

Laboratory and Medical Applications

Laboratory UV LED panels, UV LED flat panel sources are used in sterilization, disinfection, and biochemical processes that require controlled UV exposure. Their small, modular format can be mounted into benchtop stations and automated laboratory setups.

The Benefits of Flat-Panel UV LED Technology

Technical advantages of flat-panel UV LED systems over traditional lighting are as follows:

Sustainability and Energy Saving.

Industries are enjoying the reduced power consumption and increased life span of operation, with the energy-efficient UV LED flat panel systems. These systems do not contain mercury, so there is no environmental risk as with the traditional UV lamps.

Large Capacity and Color Adaptability.

The systems provide high-intensity UV light at a selectable wavelength (365nm, 385nm, 395nm, 405nm) to allow the use of a broad variety of UV-curable materials.

Compact and Modular Design

The LED panel architecture of thin form and the UV LED panel design provide ease of integration in existing production lines, be they a manual station or an entirely automated system.

Precise Thermal Management

Contemporary UV LED panels incorporate UV LED thermal control, which eliminates overheating, which means that they can be used to maintain constant working levels even in long production processes.

Industrial-Grade Reliability

These systems have long service life, consistent productivity, and low maintenance needs, as evidenced by UV LED panels to use in coating, as well as UV LED flat panel sterilizers.

Launching of UV LED Spot Curing System

The UV LED Spot Curing System is one of the most developed applications of the UV LED technology. This system is based on the flexibility and application of UV LED technology, which was created to cure quickly and with high precision in challenging production settings.

Advantages:

- The entire curing is under uniform spot coverage.

- High throughput and low heat generation.

- Adjustable wavelength structure of different materials.

- Scales both to manual and automated workflows.

- Minimal upkeep and long life span of LED.

- Energy saving and no mercury.

Industrial Benefits:

The UV LED Spot Curing System was developed in contrast to the traditional mercury-based curing systems, where the system commences immediately, the system has a low thermal effect, and thus removes the long warm-up periods. It has I/O and programmable settings, allowing it to be easily integrated into industrial control systems to support high-speed assembly lines and lab work that requires precision. To learn more, you can visit the entire selection in UVNDT.

Flat-Panel UV LED Systems: Performance and Efficiency

The contemporary UV LED flat panels are also known to produce uniform irradiation distribution, resulting in the elimination of hotspots and achieving consistent photopolymerization. The narrow-band UV LED panels enable manufacturers to adjust the wavelength to particular materials so as to maximize the speed of curing and adhesion.

In addition, the heat dissipation systems made of UV LED eliminate thermal damage on delicate materials, and the efficiency of UV lights during extended production cycles. This renders them suitable for electronics, coatings, adhesives, and in laboratories.

Features

- Water cooling will keep the temperature down: The system is thermally stable even when it is running constantly.

- It is a simple business to start: It needs minimal training due to its simple design.

- Operates independently or may be automated: Can be effectively used as a unit operation or operated in major manufacturing units.

What is the Reason to Select the UV LED Flood Curing Equipment?

The 300mm x 300mm irradiation field allows the users to approach bigger items or cure multiple smaller parts at a time. This enhances productivity as well as decreasing the number of cycles in a shift.

- With the available options of the wavelength, you can customize the curing process to be more precise to your specific material requirements. Be it transparent resins which are best handled under 365nm or colored adhesives which cure more effectively under 405nm, the equipment provides the ability to provide the accuracy and consistency of the final results.

- In addition, the application of LED technology also gives significant advantages. The lights switch on immediately, use less power and generate a minimal amount of heat as compared to the traditional UV lamps. This helps to create a more energy saving and safer operation besides shielding sensitive parts against destruction due to heat.

Science and Technology Industrial and Professional Applications

Electronics Manufacturing

These systems provide accurate UV exposure devices for PCB assembly, adhesive curing, and microelectronics assembly. The integration of industrial UV LED panels and arrays of UV LED matrices is to guarantee repeatability and high-quality results.

Printing and Coatings

UV LED panel solutions are used in the printing industry to cure inks, varnishes, and coatings very fast, and less downtime is experienced, plus the quality of the print is improved. UV LED backlight panels are highly utilized in inspection and quality control.

Laboratory and Medical Use

UV LED flat panel sterilizers and UV inspection lighting are useful in labs to provide controlled UV exposure in disinfection, testing, and analysis. Their modular nature and small size guarantee easy placement into bench-top or automated systems.

Adhesives and Sealants

The use of UV adhesives in the bonding and sealing process of applications depends on the use of UV LED flat panels to ensure consistent bonding. The flat-panel optical design is such that it delivers the UV focused, wastes less material, and enhances process consistency.

Design and Engineering Benefits

Flat-panel UV LED solutions have been developed with the highest level of versatility and efficiency:

Surface-mount UV LED panels: Provide homogenous lighting over large surfaces.

Module UV LED panel design: Multi-point scalable.

Integrated power control driver: Guarantees a controlled energy supply.

UV panel thermal substrate: Safeguards the parts and provides long life.

These design characteristics enable them to be used in industrial quality UV LED lighting as well as laboratory applications.

Conclusion

The use of flat-panel UV LED systems is changing the way industry and labs are run in terms of precision, efficiency, and flexibility. Through flat-panel technology, manufacturers, laboratories, and medical facilities can enjoy a sustainable, dependable, and complex solution that is beyond the best performance and quality standards. Learn more about all the possibilities of the high-end UV LED solutions at UVET to bring your production efficiency to the next level and realize the high-quality outcomes in all applications.