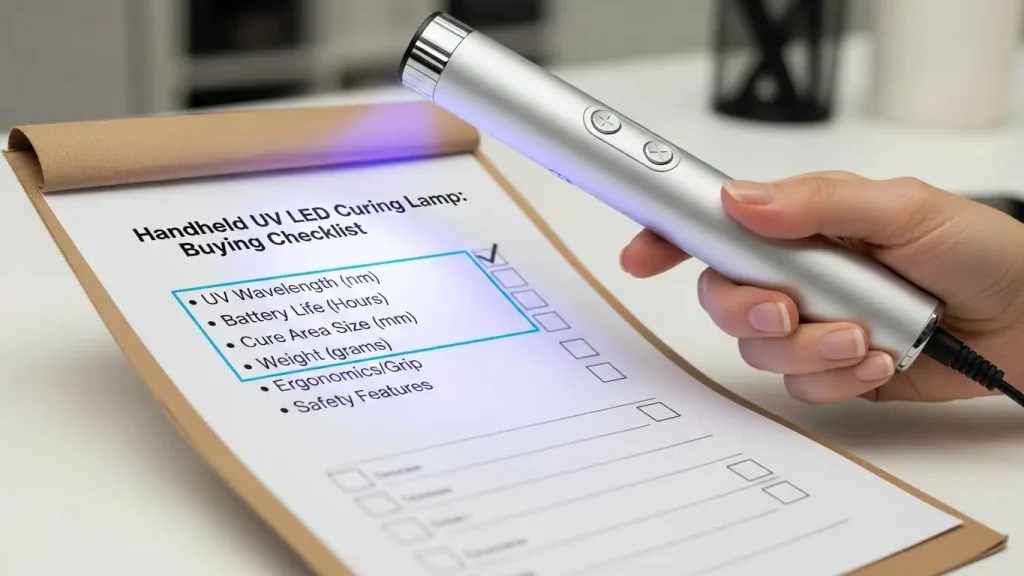

Handheld UV LED Curing Lamp: Buying Checklist

Selecting the right ultraviolet hardware for your workflow requires a clear understanding of your adhesive requirements and the physical constraints of your workspace. A handheld UV LED curing lamp provides the mobility you need for repairs and complex assembly while maintaining the high intensity of a stationary system.

This guide provides a technical checklist to help you evaluate potential tools based on their irradiance, spectral output, and thermal stability. By choosing a lamp that aligns with your specific manufacturing needs, you can reduce production downtime and ensure every bond meets its required mechanical specifications.

Why Choose a Handheld UV LED Curing Lamp

A handheld UV LED curing lamp is a portable curing tool designed to deliver controlled ultraviolet energy to adhesive bonds and small surfaces where precision and mobility matter. You will find these tools essential for assembly tasks where the workpiece cannot be moved into a fixed curing chamber, such as large-scale aerospace components or automotive glass repairs.

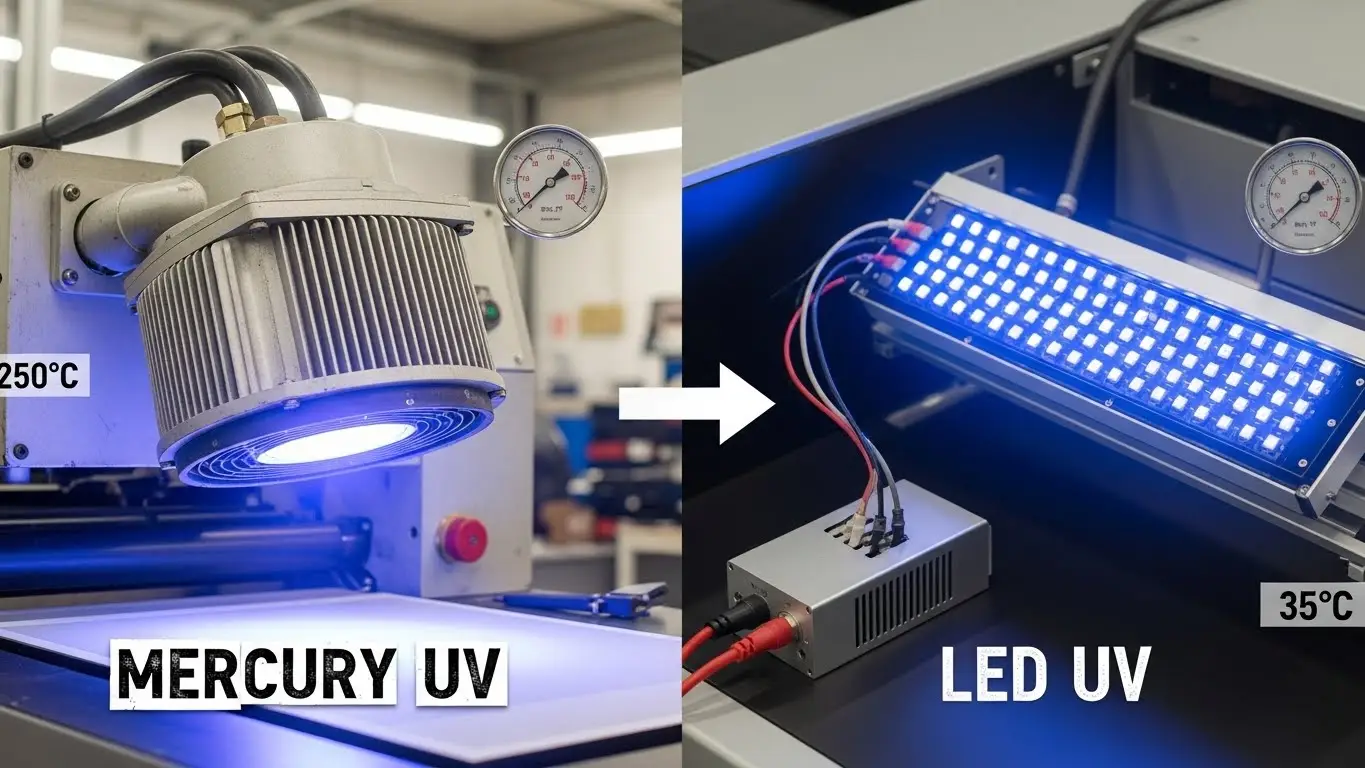

The portability allows you to reach into deep recesses or cure adhesives at varied angles to avoid shadowing. Unlike bulky mercury lamps, these compact LED units provide "instant-on" capability, meaning you can integrate them into fast-paced workflows where every second of throughput counts toward your bottom line.

What Wavelength Compatibility to Look For

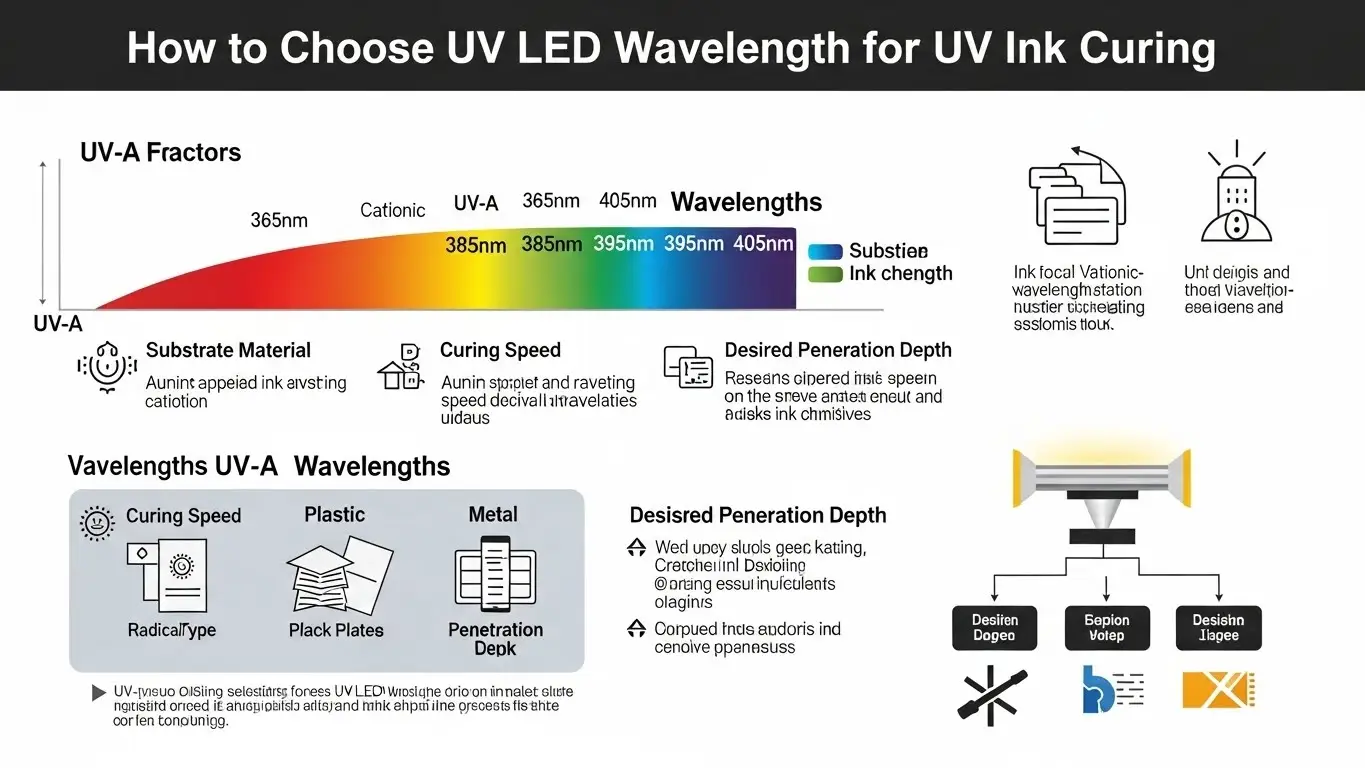

Selecting the right LED wavelength matters because adhesives and their photoinitiators respond to specific UV bands for effective cure. You should check your adhesive's technical data sheet to see if it requires a 365 nm, 385 nm, or 395 nm peak.

If you use a lamp with a wavelength that falls outside the absorption range of your resin's chemistry, the bond will be weak or remain liquid at the substrate interface. Some advanced handheld systems offer swappable LED heads, allowing you to use a single tool for different chemistries across your production facility.

How Intensity and Output Affect Performance

Intensity and output power affect how quickly and deeply a handheld UV LED lamp cures adhesive because higher intensity delivers the necessary UV dose in less time. You can view intensity ($W/cm^2$) as the "punch" of the photons; higher values are required to penetrate thick coatings or resins with dark pigments.

If your lamp has low intensity, you will be forced to increase your exposure duration or move the lamp closer to the part, which can be difficult in manual operations. High-output lamps allow for shorter cycle times, reducing the risk of substrate warping and increasing the number of parts your team can process in a single shift.

Why Ergonomics and Build Quality Matter

Ergonomics and build quality matter because comfortable handling, durable construction, and intuitive controls contribute to repeatable and fatigue-free use in field or assembly environments. You should look for a lamp with an ergonomic grip and balanced weight distribution to prevent operator strain during long production cycles.

Durable housing is also vital for industrial longevity, especially if the lamp is used in field repairs where it might be dropped or exposed to dust and chemicals. Simple, thumb-operated buttons and a clear digital status display help you maintain a stable process window without overcomplicating the operator's task.

What Battery and Power Options to Consider

Battery and power options matter because cordless operation increases mobility, while options for mains or swappable batteries extend run time and adaptability. You need to evaluate whether your typical repair job can be completed within a single battery charge or if you require a lamp that can function while plugged into a wall outlet.

High-intensity LEDs draw significant power, so you should prioritize systems with quick-swap battery packs or fast-charging capabilities. For factory-floor assembly, a tethered cord might be more reliable, whereas field service technicians will benefit most from a long-lasting, rechargeable lithium-ion system that eliminates the need for extension cables.

What Safety and Usability Features Add Value

Safety and usability features like protective shields, indicator lights, or adjustable exposure timers add value by making operation safer and more predictable. You should verify if the lamp has a built-in timer to prevent "guesstimating" exposure times, which is a common cause of under-cured bonds.

Integrated light guards or UV-absorbing shields protect your eyes and skin from reflected radiation during the curing cycle. Indicator lights that alert you to low battery or thermal issues ensure that the lamp is always operating at its peak rated intensity, protecting your quality standards from the hidden risks of equipment degradation.

What Are the Key Takeaways for Buying a Handheld UV LED Curing Lamp

The most important factors in choosing a handheld UV LED curing lamp are wavelength compatibility, intensity, ergonomics, power options, and built-in safety or control features. A well-selected lamp transforms a manual curing step into a high-precision manufacturing process.

- Match the Wavelength: Always align the lamp's output with your adhesive's photoinitiators.

- Prioritize Irradiance: High intensity reduces exposure time and improves cure depth.

- Check Ergonomics: Ensure the tool is comfortable for long production shifts.

- Verify Safety: Use built-in timers and shields to protect operators and bond quality.

What Types of UV LED Spot Curing Systems Relate to Handheld Tools?

What UV LED spot curing systems exist and how do they compare with handheld lamps? You can find a UV LED spot curing system for fixed, benchtop work, while a handheld lamp offers the portability needed for larger structures or non-standard geometries.

How Should You Use a Handheld UV LED Curing Lamp?

How do you use a handheld UV LED curing lamp properly? Following a handheld lamp usage guide ensures that your positioning and timing remain consistent, which is a key factor to check before you decide which feature set you need for your specific workflow.

How Does Wavelength Choice Affect Adhesive Cure?

How does choosing the right UV wavelength influence adhesive curing? Selecting the correct UV adhesive curing wavelengths is your most important technical step; a mismatched spectral peak will prevent the chemical cross-linking needed for structural strength.

How Does Cure Time Relate to Lamp Features?

How do intensity and wavelength choices influence how long curing takes? Understanding the variables of UV adhesive curing time helps you decide if you need a high-power lamp for fast cycles or a lower-output unit for less demanding thin-film bonds.

When Are Battery-Operated UV LED Curing Lights Useful?

When are battery-operated UV LED curing lights useful? Using battery UV LED curing lights or a battery-operated UV LED curing light is ideal for field repairs where power cables are restricted, ensuring you have high-intensity UV energy anywhere on your site.

What Is Tacky Cure and How Do Lamp Features Help Avoid It?

What is tacky cure and what lamp features help reduce it? A tacky cure usually results from oxygen inhibition; high intensity and a perfectly matched wavelength are the primary hardware features that help you achieve a hard, dry finish.

Final Thoughts

Finalizing your purchase requires a balance between technical specifications and the practical ergonomics of your workspace. While high intensity and wavelength accuracy are the primary drivers of bond quality, the battery life and build quality determine how often the tool will be available for use. By following this checklist, you remove the guesswork from equipment selection and secure a tool that is both safe and reliable for your team. The best lamp is the one that consistently delivers the required UV dose while remaining comfortable and easy to operate in your specific production environment.