What Is The Principle Behind High-Intensity UV?

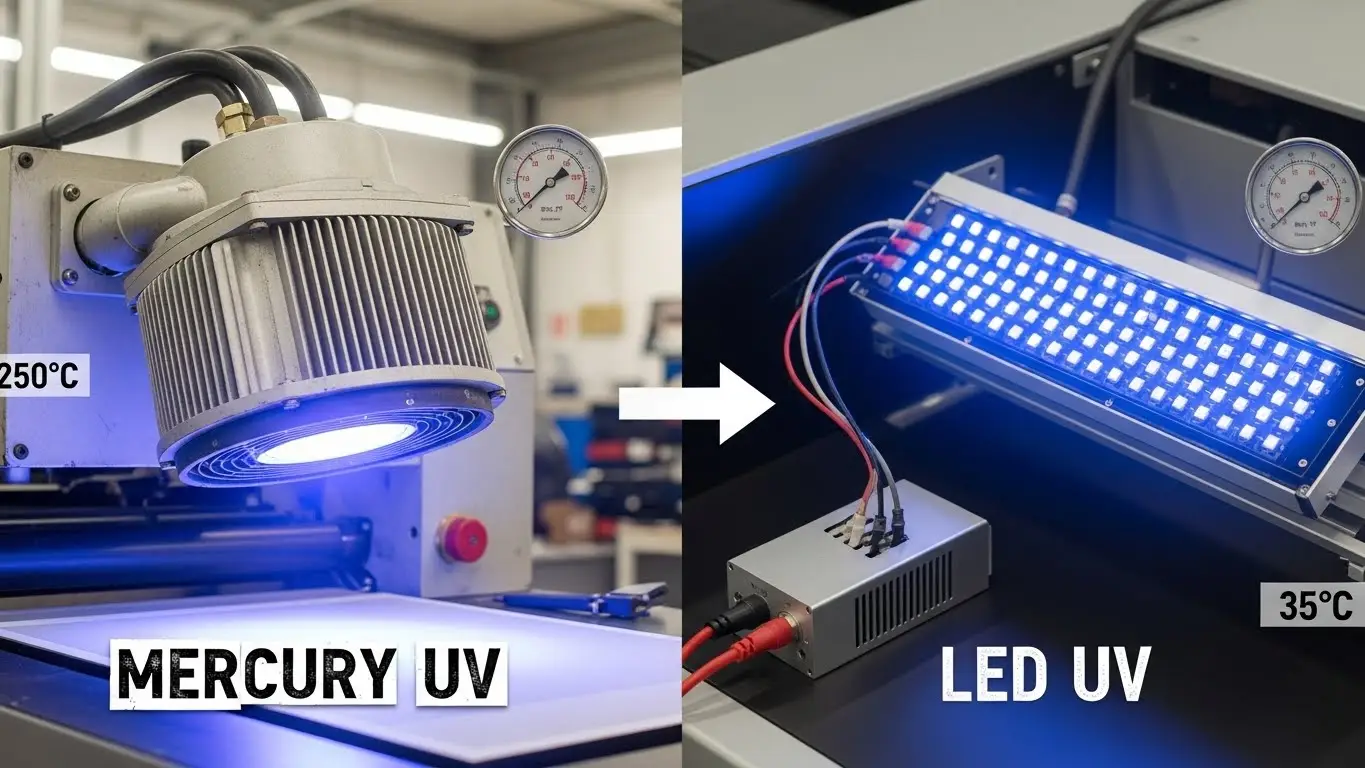

High-intensity UV has a pathogen-inactivating action because it breaks pathogen bonds germicidal UV technology. Bacterial, viral, and even fungal spores qualify as pathogens that undergo structural disintegration on exposure to such ultraviolet radiation. The photonic energy in composites and some adhesives causes their quick photopolymerization. This curing is essential for the rapid hardening of the material in the drilling, electronics, and composite parts industries. Due to its use in industrial UV lamps, UV intensity is are useful tool in photopolymer curing due to its shortwave UVC and some UVB radiation range.

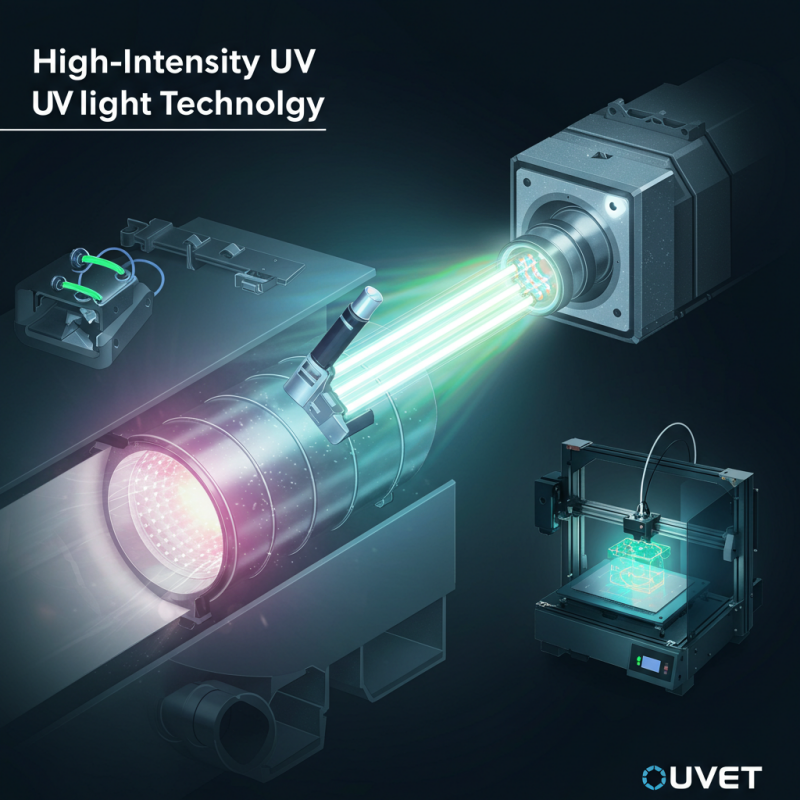

High-intensity UV outperforms all other UV LED curing devices.

- As with other high-tech, high-precision devices, high-intensity UV technology is used for UVET’s UV LED curing devices, which makes them stand out as leaders in the exacting curing technology. Such high-precision devices are equipped with uniform infrared irradiation beams. This model is innovative because it has a ring configuration that enables uniform UV irradiation for areas from 25mm to Φ50mm, making it adaptable to both low and highly sensitive tasks.

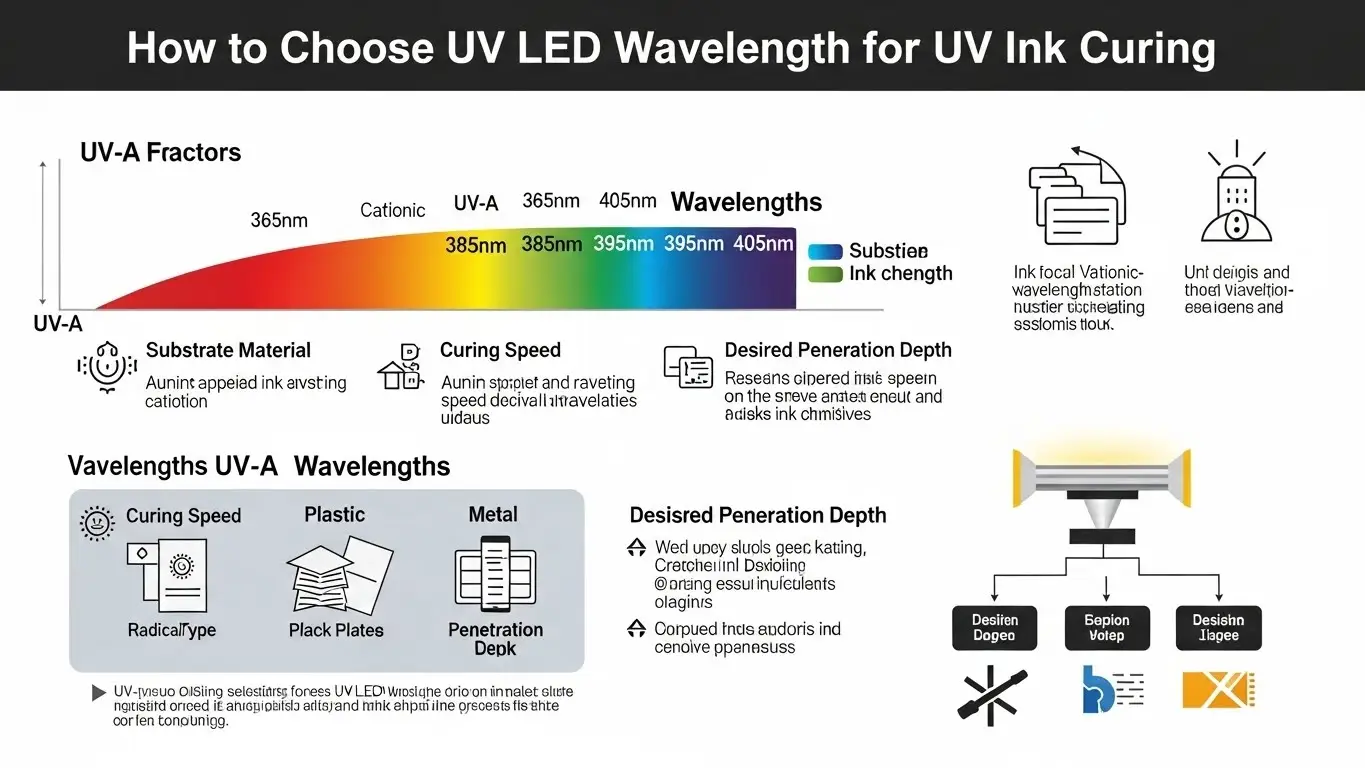

- What sets this device apart for curing is the modularity of the wavelengths offered, spanning from 365nm to 405nm. This makes it possible to tailor the curing of some materials that are UV light sensitive. Medical device bonding, electronics assembly, and the optic and optoelectronic industries, which require fast, clean, and dependable curing, can benefit from this system.

- Alongside the other features, the compact emit of the device and its water-cooled structure add to the efficiency of the device by reducing heat build-up during long production cycles. This protects sensitive parts and ensures consistent operation.

- This device has no peers when it comes to high-intensity UV LED curing devices, as they do not compare with the performance and accuracy these devices offer in high-precision applications. For manufacturers needing fast and dependable curing, there are no other choices.

Applications of High-Intensity UV Technology

1. UV Curing Systems

In industrial printing, 3D manufacturing, and electronics, UV light applications in curing inks, coatings, and resins are instrumental in accelerating the curing processes. This improves efficiency while reducing downtime.

2. Healthcare & Laboratory UV Equipment

High-output UV lamps are commonly employed for the disinfection of medical equipment, laboratory surfaces, and diagnostic tools. This method is ideal for sterile maintenance as it is devoid of chemicals and residues.

3. HVAC UV Systems

Installed UV lamps within air ducts actively enhance indoor air quality by eliminating microbial contaminants in offices, schools, and hospitals.

- Industrial Benefits of High-Intensity UV

The unparalleled efficacy of high-intensity UV systems makes them one of the greatest assets for industrial applications. Such environments prioritize productivity and consistent operation, which these systems offer. Their ability to provide rapid, chemical-free sterilization makes them indispensable in manufacturing, cleanrooms, packaging, and environmental processing.

Advantages of High-Intensity UV for Industrial Applications

High-intensity UV LED curing devices provide numerous benefits across various precision-driven industries. Here are the key advantages, broken down by application:

- Electronics Manufacturing

- Ideal for micro-bonding, sealing, and circuit assembly

- Minimal heat output protects delicate components

- Faster curing boosts throughput and productivity

- Medical Device Production

- Clean, mercury-free curing meets hygiene standards

- Safe for bonding sensitive materials like catheters and syringes

- Enables precise and durable bonding of transparent components

- Eco-friendly (no ozone-depleting chemicals)

Unlike traditional sterilants, UV-C technology does not release harmful residues or ozone-depleting gases. It is not only safe but also supports sustainability goals.

- Low operational costs after initial setup

Maintenance costs are low, and infrequent lamp replacements mean there are no costly supplies to enhance profitability.

- Streamlined Industrial Systems Integration

Most industrial UV light units are compact and designed to fit within a given space. They interface well with conveyors, ducts, or production lines as a part of the existing system.

- No Heating Damage (Especially in UV-based LED systems)

UV-C LEDs pose virtually no risk concerning heating, which may damage delicate electronics, plastics, and pharmaceuticals. Boosting hubs to enhance production is achieved easily with 8 UV solutions that offer unmatched value in current times.

Is High intensity UV Safe?

- Utilized correctly, high-intensity UV is safe.

As with any system utilizing high levels of UV, precautions need to be taken for the safety of the user. Safety protections like hardware disabling triggers, enclosures, and dosage timers must be put in place. Protective measures are critical because direct exposure to these lights can cause damage skin and ocular harm.

- Installation and operations should adhere to OSHA and IEC requirements

A high-intensity portable UV sanitizing tool such as this is found in clinics, hotels, and even homes.

Best Practices for Routine Maintenance and Monitoring

Your high-intensity UV sterilization system demands scheduled deep sanitization to maintain peak effectiveness. Higher-level systems require more precise diligence for them to be operational and safe.

Steps to best sustain effectiveness and safety

- Regular cleaning of quartz sleeves

Obstructions such as dust or biofilm hinder the emission of UV light. Cleaning quartz sleeves enhances systems' ability to transmit UV light, thereby maximizing germicidal output.

- Change lamps after 9,000 – 12,000 hours of usage

All lamps emit UV l888ight less intensely over time. For optimal disinfection, adhere to the manufacturer's suggested lamp-lifting and repla8cement schedule.

- Make use of calibrated UV output measurement devices.

Measuring the output of UV radiation using analyzers and/or dosimeters helps in discovering output sinks as mentioned above.

- Maintenance: Calibration of the sensors every six months

Hygiene-sensitive environments rely on accurate sensor data for real-time measurement of UV fluence, so routine recalibration is essential.

Conclusion

Focusing on the new brightness shows how far high-intensity ultraviolet light impacts technology. Through its application, materials and surfaces can be sterilized, cured, and shielded in a matter of minutes. All high-precision industries will benefit from this form of energy. Helps achieve remarkable success in strengthening the production processes by incorporating it into medical cleaning procedures and even in improving air quality indoors. Visit UVET.