High-Power UV LED Curing System: Specs and Real-World Use

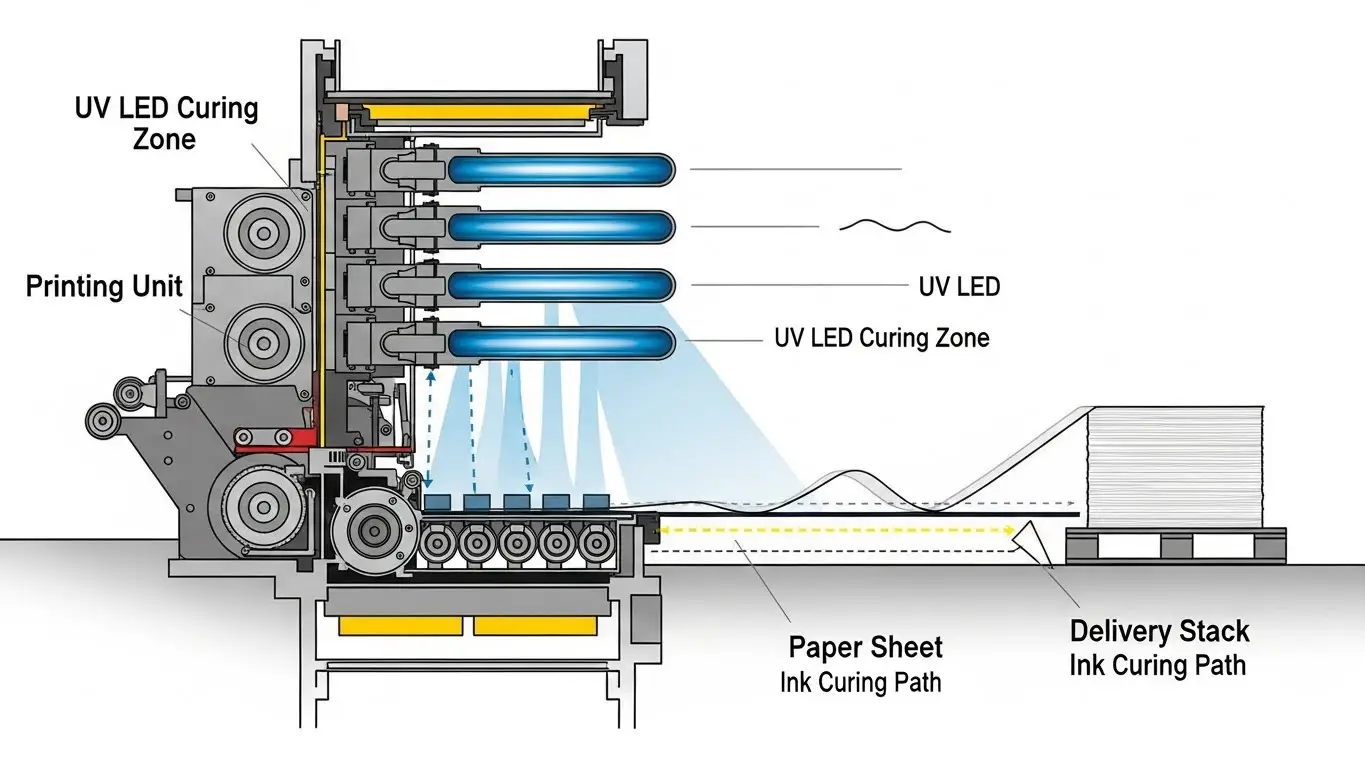

In high-speed industrial environments, the ability to deliver massive amounts of ultraviolet energy instantaneously is the difference between a successful production run and a costly failure. A high-power UV LED curing system is often the engine behind demanding applications like wide-web printing, high-speed fiber coating, and deep-section electronics encapsulation.

This guide breaks down the technical specifications that define high-output hardware and explains how to interpret these metrics in the context of your specific manufacturing needs. By aligning these high-performance specs with your operational reality, you can achieve a more stable, efficient, and predictable curing process.

What Defines a High-Power UV LED Curing System?

A high-power UV LED curing system is characterized by elevated UV output and capability to deliver high intensity over large areas or at high throughput. You will find that these systems typically provide irradiance levels significantly higher than standard benchtop units, often exceeding 16-20 W/cm².

They are engineered with high-density diode arrays that can maintain these extreme energy levels over long production shifts. Unlike low-power versions used for spot curing, high-power systems are designed for full-width integration on automated lines where every millisecond of exposure must count toward a complete chemical reaction.

What Core Specifications Matter in High-Power Systems?

Evaluating high-power UV LED systems means looking at specs such as peak intensity, total power delivery, uniformity across the curing path, and how these relate to application needs. You must look beyond just the "peak" irradiance number and consider the "energy density" or dose that the system can deliver at your specific line speed.

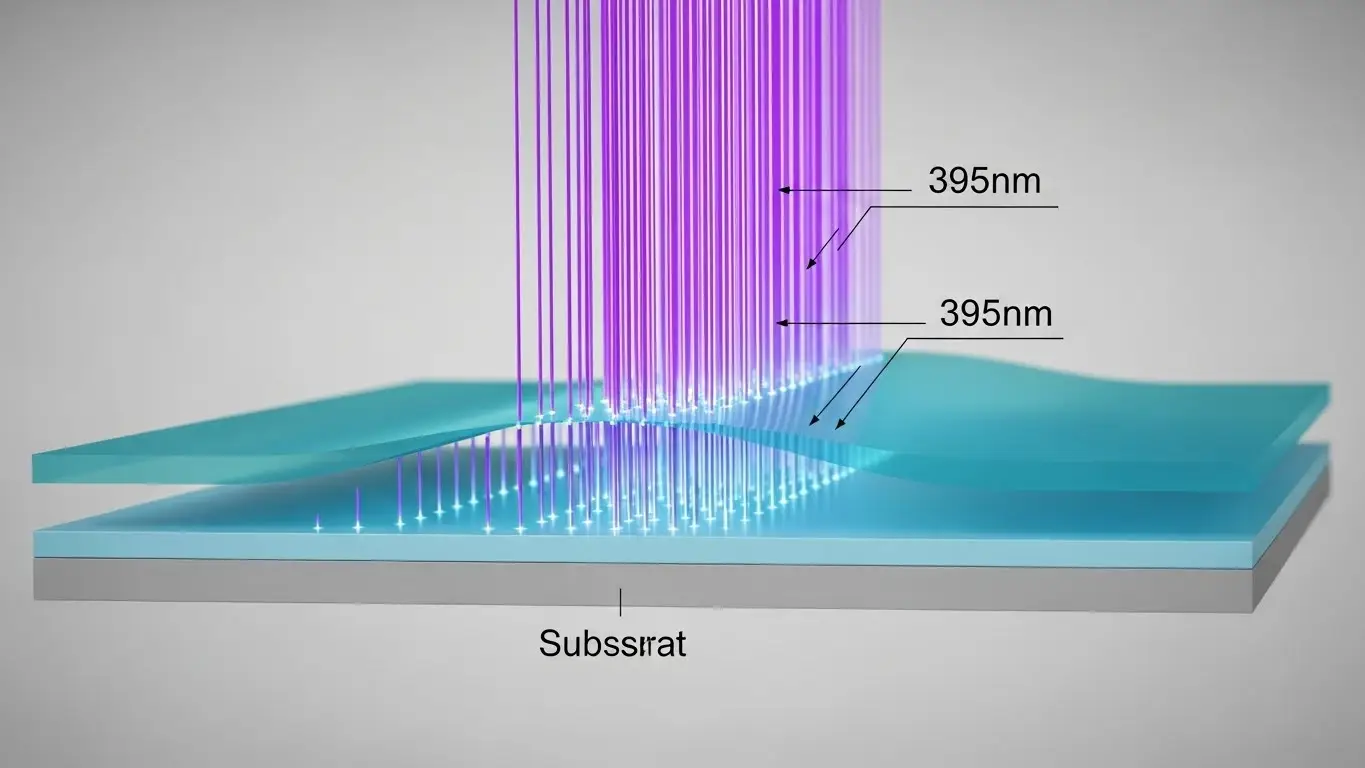

The total wattage of the system indicates the electrical capacity, but the irradiance at your actual working distance is what dictates the success of the cure. Furthermore, the spectral width of the output must be tightly controlled to ensure that the 365 nm, 385 nm, or 395 nm peak aligns perfectly with your material's photoinitiators.

How Does Cooling Impact High-Power UV LED System Performance?

Cooling strategies like air or water cooling become critical in high-power UV LED systems because increased output generates greater thermal loads that must be managed to preserve stability and reliability. When you drive LEDs at high currents to achieve extreme intensity, the diodes generate substantial internal heat that can lead to "thermal decay" if not moved away.

Water cooling is the preferred method for the most powerful systems because liquid can absorb and transport heat much more efficiently than air. Maintaining a stable junction temperature prevents the UV output from drifting, ensuring that the last part cured in a shift receives the exact same energy as the first.

What Role Does Intensity Play in High-Power UV LED Curing?

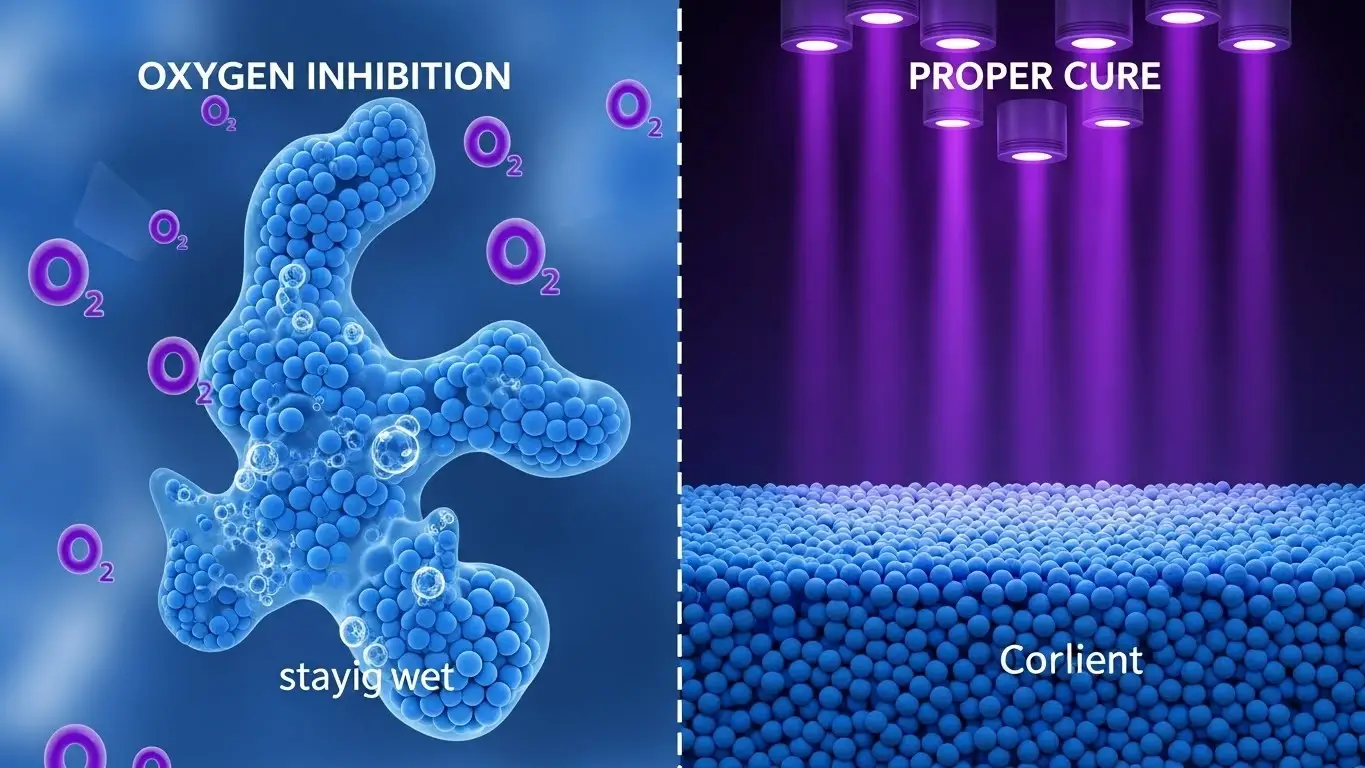

Intensity in high-power systems directly affects cure speed and material penetration, making it a key spec for matching system capability to production needs. You will find that high intensity ($W/cm^2$) is essential for overcoming oxygen inhibition in thin coatings, allowing the surface to harden instantly before it can be compromised.

In thick-film applications, high intensity provides the "driving force" needed for photons to penetrate deep into the material, reaching the base layer to ensure structural adhesion. Without sufficient power, the material may cure on top while remaining liquid or tacky underneath, leading to delamination or mechanical failure.

How Should Dose and Uniformity Be Considered for High-Power Operation?

In high-power UV LED systems, maintaining consistent dose and uniform energy across the curing field ensures dependable curing results and high throughput. You must ensure that the intensity profile is "flat" across the entire width of the lamp head so that the edges of your substrate receive the same energy as the center.

Uneven energy distribution can lead to localized under-curing, which is a common cause of rejects in wide-format printing and textile manufacturing. By matching the dose ($J/cm^2$) precisely to the material's requirements and the conveyor speed, you create a robust process window that can accommodate minor variations in production conditions.

What Operational Factors Should You Evaluate With High-Power Systems?

Evaluating high-power UV LED systems for real-world use involves considering duty cycles, environmental conditions, production speed, and how those factors interact with spec metrics. You should perform a technical audit of your line using the following criteria:

- Production Speed: Determine if the system can deliver the required dose at your maximum conveyor RPM.

- Duty Cycle: Verify if the cooling system can handle continuous 24/7 operation without output decay.

- Ambient Environment: Ensure your facility's temperature and air quality won't compromise the cooling efficiency.

- Substrate Distance: Confirm the intensity specs are rated at your actual working height, not just at the lamp window.

- Material Sensitivity: Evaluate if the radiant heat from high-power diodes will affect heat-sensitive substrates.

What Maintenance Practices Support High-Power UV LED Performance?

Maintaining high-power UV LED curing systems requires regular checks of cooling, optics, and output consistency to sustain performance and uptime. You will notice that because these systems run at the "edge" of their thermal capacity, even a small restriction in a water line or a dusty air filter can lead to a significant drop in intensity.

Cleaning the output window is a non-negotiable daily task, as any overspray or debris will absorb UV energy, heat up the glass, and potentially damage the diodes underneath. Periodic radiometer mapping is the only way to confirm that the system is still delivering its rated power and that uniformity across the field remains within spec.

What Are the Key Takeaways on High-Power UV LED Curing Systems?

Successful high-power curing is a result of balancing extreme energy output with robust thermal management and precise process control. You get the most reliable results when you choose a system that offers headroom above your minimum required intensity.

- Intensity triggers the cure and overcomes chemical inhibitions in high-speed lines.

- Water cooling is essential for maintaining output stability in the highest-power arrays.

- Uniformity across the width is critical for ensuring consistent quality in wide substrates.

- Regular maintenance and mapping protect your investment and prevent production drift.

What System Specifications Should You Look at in UV LED Curing Systems?

Understanding the nuances of power and irradiance ratings is the first step in equipment selection. You can learn how to interpret UV LED curing system specs to find the right fit for your line.

How Does Water Cooling Work in High-Power Systems?

For the highest-output arrays, liquid thermal management is a technical necessity. Read about the design and benefits of UV LED water cooling to see how it supports high power.

How Do Air-Cooled and Water-Cooled Systems Compare for High-Power Use?

Choosing the right cooling method depends on your intensity "ceiling" and duty cycle. Explore our side-by-side comparison of cooling methods for more technical context.

How Does Intensity Affect Curing in High-Power Applications?

High intensity is the primary driver of through-cure and surface hardness. Review how UV LED intensity levels impact your material's final physical properties.

How Is UV LED Dose Calculated in High-Power Settings?

At high speeds, the relationship between power and time becomes even more critical. Use our guide to calculate UV LED dose to maintain your quality standards.

How Does Uniformity Affect Curing Quality in High-Power Systems?

Even energy distribution prevents soft spots and bond failure across wide substrates. Learn why UV LED curing uniformity is a key indicator of system health.

How Does Lamp Temperature Influence High-Power Operation?

Heat is the enemy of stable UV output and long diode lifespan. Explore the relationship between lamp temperature and performance in high-power configurations.

What Maintenance Practices Support Consistent Performance in High-Power Systems?

Proactive care is the only way to ensure your system continues to meet its high-power ratings. Follow our UV LED curing system maintenance checklist for industrial uptime.

Final Thoughts on High-Power UV LED Systems

Selecting a high-power UV LED system is a transition from standard manufacturing to high-precision, high-volume industrial production. While these systems offer the promise of incredible speeds and superior bond strength, their success depends on a holistic approach to system design, including robust cooling and disciplined maintenance.

By focusing on the irradiance reaching the part surface and the stability of that energy over time, you can eliminate the variables that lead to production failures. The best high-power system is one that integrates seamlessly into your workflow, providing the intense energy required while remaining thermally stable and easy to maintain.