Brief introduction

The High-power UV LEDs, which are of high power, are revolutionizing the industries that depend on UV light. These solid-state devices also provide better performance with high intensity, longer lifespan, and are also environmentally friendly, unlike traditional mercury lamps. Its application is expanding rapidly in terms of industrial curing and 3D printing, and sterilization and purification of water.

What Are High-Power UV LEDs?

High-power UV LEDs are ultraviolet light-emitting diodes that generate high radiant flux with narrowband wavelengths of 365nm, 385nm, 395nm, and 405nm. These systems have high-output UV LED chips embedded on robust substrates with high-end thermal management devices. Compared to standard LEDs, the high-power UV diodes are capable of operating at higher levels of current and retaining their level of stability. This renders them perfect for UV curing technology, disinfection, sterilization, and industrial exposure systems.

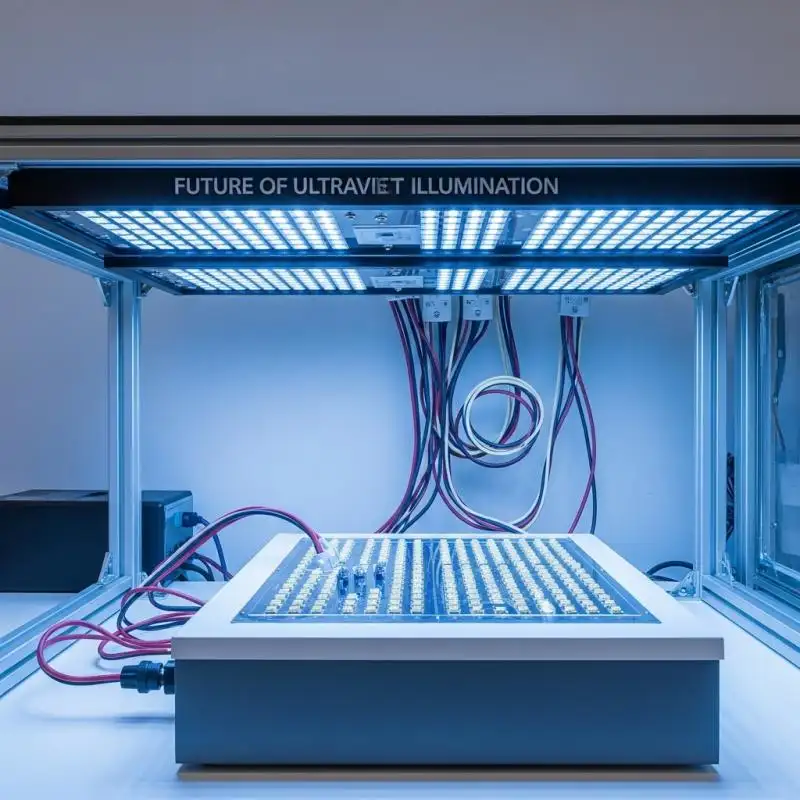

UV LED Flood Curing Lamp -High Power, Efficient, and Reliable

The UV LED Flood Curing Lamp Model

UVSS-120S2 is a product designed to provide high performance and the curing of a wide variety of industrial and electronics products. This system has a large area of 150mm x 100mm of irradiation that guarantees uniform and effective curing of large surfaces. It is especially suitable for the production of electronics, medical devices, optics, and optoelectronics where precision, reliability, and speed are critical.

Big Irradiation Area of High-Volume Curing

The most notable characteristic of this UV LED flood curing lamp is its 150mm x 100mm curing window. Such broad coverage enables the user to cure large substrates or several small components at a single pass, enhancing production throughput and minimizing production time. In batch or continuous assembly lines, this lamp can be used to achieve consistent UV exposure with no hot spots or cure variation.

Wavelengths to be versatile

The system is provided with four adjustable wavelengths: 365nm, 385nm, 395nm, and 405nm. This allows it to be used with a wide variety of UV-curing adhesives, coatings, and inks. Users are allowed to select the wavelength that will best fit the absorption spectrum of the material they are using, and this gives:

- Faster curing times

- Strength of bonding and adhesion.

- Improved product quality and life span.

Such flexibility makes UVSS-120S2 a reliable choice in industries that need accurate curing of various materials.

Continuous Operation Design

The lamp is designed using a fan-cooled mechanism so that it does not overheat when used for prolonged production. This UV LED flood curing lamp has instant on/off control in contrast to the classic mercury lamps, which have to warm up and cool down before the lamp is operational. This design ensures:

- Constant performance over a long period.

- Less downtime and maintenance requirements.

- Reduced energy usage and heating load.

Consequently, this leads to increased productivity and cost savings by the manufacturers.

Versatile Interference in production lines

UVSS-120S2 may be used as an independent system or simply connected to automated production lines. Its small, robust construction can easily fit within small production areas and provides a high-powered curing with uniformity. The industries that are facilitated by this flexibility include:

- Electronics production, including LED bonding, PCB assembly, and display production modules.

- Medical equipment- Adhesive covering, bonding components, optical sensor assembly.

- Optics and optoelectronics Lens bonding, coating applications, precision assemblies.

Key Features at a Glance

- 150mm x 100mm area of irradiation - Accommodates big format curing.

- Adjustable wavelengths (365nm, 385nm, 395nm, 405nm) -Provides the best curing results.

- Fan cooling system -Ensures good, constant operation.

- Immediate on/off light-emitting diodes - Removes cold-up time or warm-up time.

- Energy saving technology -Saves operational cost.

- Small and lightweight construction - not bulky and fits well into the production lines.

What is the Benefit of the UV LED Flood Curing Lamp?

UVSS-120S2 is the best choice of the high-power UV LED that would be used by manufacturers who want speed, accuracy, and energy savings. Comprehensive area of curing, flexibility in wavelength, and strong functionality are some characteristics that make it suitable for small facilities and sophisticated production lines. In selecting such a system, you have:

- Faster throughput and increased cycle time.

- High quality of the products and consistency in curing.

- Energy-efficient LED technology will save money in the long term.

Advantages

- High Reliability: Thermal management is stable to ensure continuous operation.

- Economical: Reduced electricity expenditure lowers electricity bills.

- Long Lifespan: More than 30,000 hours of continuous UV output.

- Small Dimension: Perfect for fitting into small systems.

- Friendly to the Environment: Mercury-free and environmentally friendly.

- Regular Results: Constant output of light will ensure consistent curing and sterilization.

Selecting the Right High-Power UV LEDs

1. Define Your Application

- The use of adhesives and coatings to cure them with UV-A (365–405nm)

- Sterilization and disinfection UV-C (265- 280nm).

- Fluorescence excitation/ diagnostics UV-A (365nm)

2. Verify Output Power

Output intensity is measured in mW/cm 2, and it defines the rate of curing and sterilization.

3. Check Cooling Systems

Use modules that have built-in fans, heat sinks, and water cooling to achieve maximum reliability.

4. Power Supply Compatibility

Make sure of proper voltage and current specifications (12V, 24V, constant current drivers).

5. Service Life and Certification

Search the devices possessing LM-80 test results and industry certifications to ensure performance.

Market Trends

The industrial UV lighting is in increasing demand in industries. The market of the UV LEDs is projected to increase more than 20 percent per year, according to LEDs Magazine, because of the increasing application in water purification, disinfection, and electronics manufacturing. We are ahead of such trends at UVET with its custom high-power UV LED modules that meet the industrial, medical, and research requirements.

Future of High-Power UV LEDs

Through ongoing research and development, UV LEDs continue to get stronger, smaller, and less expensive. The future includes:

- Next-gen UV LED arrays for massive curing.

- AI-supported UV exposure systems to produce with accuracy.

- Green sterilization in healthcare across the world.

Conclusion

The high-power UV LEDs are not an option anymore; it is a standard in the industry. They provide efficiency in energy, reliability, a small size, and environmentally friendly operation, which is applied in printing and electronics industries, medical sterilization, and water purification. In case you desire to learn about unique UV LED products, go to UVET, and see how our high-power UV modules can revolutionize your processes.