How Does UV LED Inspection Work? Applications & Benefits

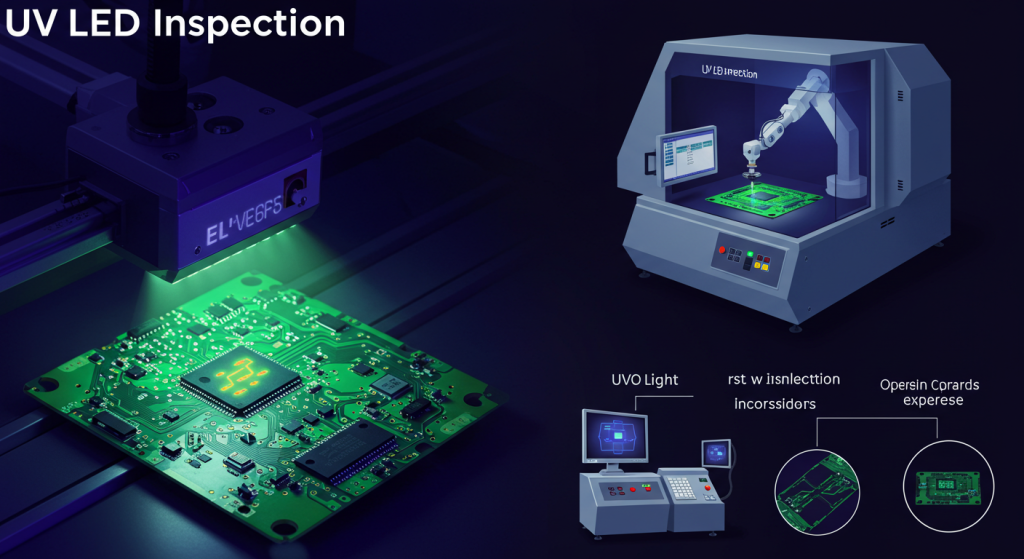

How is Visual Inspection Conducted With UV LEDs?

Among the other methods of non-destructive testing (NDT), UV LED inspection stands to cope with surface flaws because, unlike other methods, it does not alter the structure of the body. This method employs ultraviolet light to render detectable flaws that are normally invisible to the naked eye. In this post, we will discuss the workings of UV LED inspection, its applications in different sectors, and the advantages of this method in comparison to others.

Beneath Understanding the ECG Machine: Principle of Operation and Parts

Inspection under ultraviolet light makes use of the fluorescence principle. The most common type in this class is, without a doubt, UV LED, which emits light at 365 nm (UV-A band). Those lamps respond with the appliqué dyes and also with the disodium salt of fluorescein, which is used in the construction of flow cell technology. The dyes emit UV radiation of certain wavelengths and surface indications such as laps and porosity\corrosion are bound to illuminate. This inspection technique is characterized by the following components:

• UV LED Lamps: These perform the crucial function of supplying Ultraviolet light to activate processes in the fluorescent dyes.

• Application of Fluorescent Dyes: These are applied on the upper area of the material, which makes detection of surface flaws better when a light source with UV is employed.

• Inspection Booths: Cavities are inspected by using handheld lamps or other light sources in inspection booths.

What is the Process of UV LED Inspection?

How does UV LED inspection work? For Non-destructive Testing (NDT) using UV-A light with a wavelength of 365nm for additively manufactured parts, surface-revealing flaws will be detected through fluorescence. When a substance is subjected to ultraviolet radiation, it undergoes fluorescence, emitting part of that energy in the form of light, which is visible to the human eye.

- The sequence starts with applying a fluorescent tracer to the component's surface, then, after some time, any excess oil needs to be wiped out. The component is placed into a workstation lamp that is equipped with a UV LED. The detection of oil embedded in the available voids is what the researcher will look for. Under the conditions where the decontamination boundary is maintained, the dye that does not diffuse will be incandescent under black light, thus outlining possible fractures, leaks, pores, or some other deficiencies.

- LED UV lamps are used in advanced forensic black light applications, and automotive and aerospace industries for crack, leak, weld, and cleanliness verification due to their non-hazardous properties, efficiency, durability, and overall accuracy in detecting flaws.

- For safety and quality inspection, check the high-stakes industry UVNDT operates. Because of their accuracy without needing to inflict harm on the object being tested, they provide thorough inspections.

- E-lettered Exon LED inspection incorporates the use of fluorescence, which revolves around the device’s core revolves around. Under electric stimulation emitted by electric interactions with fluorescent materials, which are suspended in an active state, while the surroundings are dark, they emit energy dubbed ‘glow’ or visible light, allowing for flaw detection which can be performed without breaching material integrity, NDT.

- NDT is crucial when it comes to conditions and circumstances where the material’s strength and structure undergo heavy stress. Because reliability and safety are always a requirement, the ability to use LED UV to detect flaws without compromising the part’s functionality allows for this.

Universal Applications to Other Industries

Because of the faster detection method of surface flaws, UV LED inspection is helpful for so many areas, which include:

• Aerospace: Using UV LED for structural checks of the turbine blades and fuselage sections_ to ensure these critical components have no cracks.

• Automotive: Defect and crack checks are performed on the engine parts and the welds for their safety and performance.

• Electronics: Examination of solder joints and circuit boards for micro fractures, which lead to failures.

• Medical Devices: Quality assurance for surgical instruments and syringes.

• Forensics: The detection of bodily fluids and other marks on the crime scene.

• Food Safety: In the food processing area, as a checking inspection for cleanliness and contamination.

The Advantages of UV LED Inspection Technology

UV inspection has numerous advantages compared to other methods of inspecting products as a result of technological advancements:

• Enhanced Detection: Surface defects can be found easily with a high concentration of UV light.

• Economical: Manufacturing and maintenance costs for LEDs are lower as they consume less power and have longer lifespans.

• Versatility: Inspections can be done in many locations, including remote ones, with the aid of handheld UV LED lamps.

• Health: Unlike other technologies, UV LEDs are safe for operators and the environment as they emit low heat and do not contain mercury.

• Full Compliance: Dependable and consistent outcomes can be achieved with industry guidelines like ASTM E3022, to which UV LED lamps can be built to comply.

Considerations in the Implementation of UV LED Inspection

How does UV LED inspection work? These are the very important factors that must be considered during the planning of any UV LED inspection to guarantee success:

• Setting of IFD Signaling Wavelength Selection: IFD signaling can be realized on FDDOP with polymer at approximately 365nm. This can be done using Fluorescent Dyed Defect Obscuring Panels.

• Dosage of Emitted Irradiance: The output irradiance should be strong enough to achieve the intended purpose, either directly or indirectly.

• Increasing Contrast: The use of UV materials can also aid in increasing the contrast of an image produced with DONT imaging or CRT imaging, as well as making the image clearer.

• Result Enhancement: During the inspection, the complete blackout of any light will greatly improve the chances of seeing fluorescent indications.

What is New with UV LED Inspection Technology?

What is new with the UV LED-based inspection systems? These are some of the areas in development:

• Automated Processing Balance: In high throughput environments, development is underway in _Automated UVDAC_ or Automated UV LED Data Capture.

• Immediate Actionable Inspection Results: AI algorithms are being integrated for real-time data processing and faster access to results for immediate feedback.

• Dosing of Operator: These are more portable and compact; however, the new compact systems enable harsher-to-reach areas to be accessed.

Conclusion

Non-destructive testing, ultraviolet (UV) LED inspection, is a relatively new technology. As with many testing methods, it is performed at reasonable as well as safe distances from and on the part under inspection. Surface break indications are inspected during the process, and results are analyzed within a scan. Several solid surfaces have started making use of the method, indicating its importance and value in contemporary assurance of quality. There is a reason to think that UV LED will greatly assist in making the inspection process safer, more reliable, and more effective around the world. Visit UVET.