How Precise is UV LED Spot Curing? Dive into Curing Precision

How Precise is UV LED Spot Curing? Unveils the Science Behind Precision?

In advanced forms of manufacturing, UV Light Emitting Diode (LED) spot curing is often considered a fundamental technology across industries ranging from medical devices to microelectronics. UV LED curing achieves unrivaled precision. But how precise is UV LED spot curing? The following discussion analyzes the precision levels of UV curing methods using technical parameters, performance metrics, and real-world applications.

Understanding UV LED Spot Curing Precision

UV LED curing is the procedure of concentrating ultraviolet rays onto a predetermined portion of an item to photo-chemically induce a specific reaction, usually hardening an adhesive or coating. The factors below have an impact on precision in all these steps:

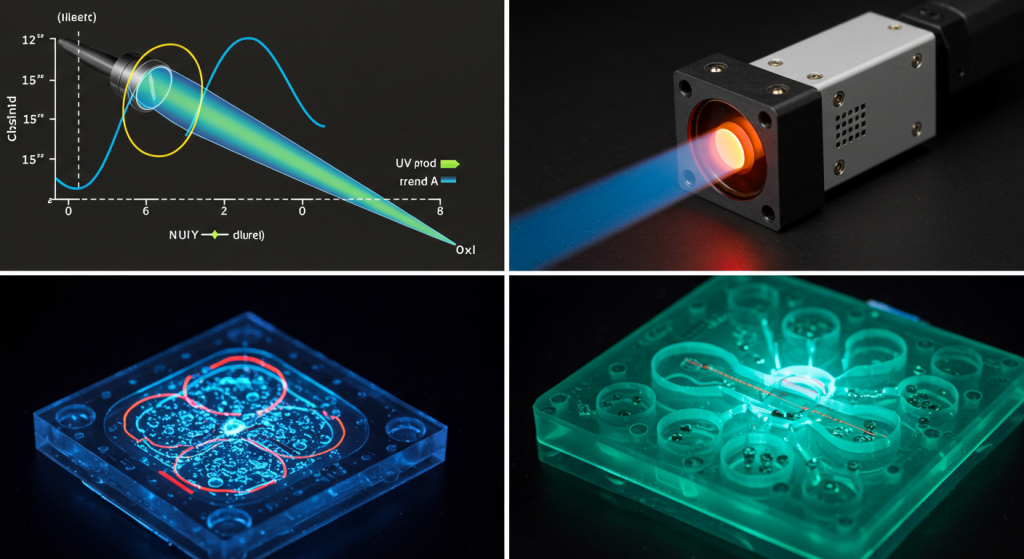

• Spot Size Control: Radial light concentrating systems are highly developed, giving rise to the ability to achieve spot sizes from diameters of a few millimeters to sub-millimeter scales. Focusing UV light on a defined spot size has proved to be crucial.

• Irradiation Homogeneity: To achieve consistent curing in the targeted area, uniform distribution of UV light intensity must be maintained. To ensure that there is no uneven curing, high-quality UV LED systems make sure that there is uniformity of irradiance.

• Depth of Cure: The amount of UV light exposure affects how deep the curing process will be. Achieving optimal depth requires careful exposure control in terms of time and intensity to avoid over- and under-curing.

Key Performance Metrics

In evaluating the effectiveness of UV LED Spot Curing, these are the metrics considered:

1. UV Intensity (mW/cm²)

Power per unit area of surface irradiated is referred to as UV intensity. When using high-power LEDs, curing of materials can be done in a shorter duration and a more efficient manner. The L9000 UV LED spot curing lamp, for example, features intensities of up to 7,500 mW/cm² at 3 mm focal points so that curing can be quick and thorough. At focal points as small as 3 mm, the L9000 UV LED spot curing lamp offers intensities of up to 7,500 mW/cm², ensuring rapid and thorough curing.

2. UV Dose (mJ/cm²)

It is the total amount of energy expended or supplied per unit of area, which is the dose rate times of exposure duration. It becomes critical that the appropriate amount of UV dose is provided so that it guarantees adequate curing. A dose of 20 seconds can cure a 20 mm diameter adhesive spot with mJ/cm² of 6,000 mJ/cm².

3. Wavelength Selection

The choice of UV light has a direct impact on curing effectiveness. The selection also determines material compatibility. The optimal wavelength for energy absorption is crucial to achieving the best results. Used wavelengths include 365 nm, 385 nm, 395 nm, and 405 nm.

The ability to adjust spot size permits laser curing to be performed in a more targeted manner. The L9000, for example, has spots of 3 mm to 12 mm and has a focal length of 9 mm to 30 mm, thus offering versatility for other uses.

Applications Requiring High Precision

UV LED spot curing is known to have high precision, and so it is utilized in various high-end applications such as:

• Medical Device Assembly: Precisely bonds components to ensure the reliability of devices and safety for patients.

• Electronics Manufacturing: It allows accurate curing of adhesives in components such as sensors and microchips.

• Optics Bonding: Consistent curing of optical lenses and other components to guarantee standards of performance.

• Automotive Components: Attaining proper adhesion for small parts to improve the quality of vehicle assembly.

• Dental Composite Curing: Curing of dental materials for structural integrity of aesthetic restoration works.

Challenges in Achieving Precision

With all the improvements, these factors can still affect the precision of UV LED spot curing:

1. Oxygen Inhibition

Surfaces can be affected by the oxygen curing. The use of inert atmospheres or choosing resistant formulations would alleviate the inhibition problem.

2. Managing Heat Issues

Both the LED and the material being cured can be damaged by excessive heat. To sustain performance and longevity, effective cooling, such as the use of forced air cooling systems, is essential.

3. Compatibility with Cure Materials

Selecting materials for UV curing processes is a crucial step; therefore, not every material qualifies for UV curing. Achieving optimal results requires the use of adhesives and coatings specially designed for UV LED curing.

4. Effects of Shadowing

Incomplete curing could be the result of shadowing caused by irregular surfaces. Adjusting exposure parameters can help address shadowing on flexible light guide surfaces.

Enhancing Precision: New Developments

Focus on the precision of UV LED spot curing has been enhanced by recent developments in technology:

• Integrative radiometers and intensity monitors have enabled real-time adjustments through Closed-Loop Feedback Systems. Compensating for LED degradation during the curing process has been made possible.

• Enhancing throughput and reducing cure times have been made possible by high-intensity modern LEDs.

• Adjustable optics light output tailored towards specific ailments has facilitated optimizing curing on systems with Customizable Optical Profiles.

Equipment & Technology

Through sophisticated UV LED curing equipment, remarkable precision is achieved. These systems are not just simple lamps; they have been designed for utmost control, hence the term intricate systems.

• UV LED Spot Curing System:

Like other integrated units, these include a power supply, a controller, and a UV LED light source. They do the major work in UV curing.

• High-Precision UV Light Sources:

Claimed to be the system’s core, these sources are designed with great attention to reliable and strong UV output, which is homogeneous both spatially and spectrally.

• UV LED Controller:

This unit functions as the brain, capable of modulating UV output in terms of intensity, exposure duration, and pulse sequencing. More sophisticated controllers allow for closed-loop control of UV output. This means sensors measure the level of UV output and control the power supplied to maintain a fixed intensity, making the UV curing process repeatable.

• Automated UV Curing Systems & Robotic UV Spot Curing:

For extreme sophistication, automation enhances precision for high-volume applications. Curing is incorporated in the production line with automated UV curing systems, while where positional accuracy of the spot is required, robotic UV spot curing systems have the upper hand. No other systems can ensure that the UV spot will be positioned accurately time after time.

Conclusion

How precise is UV LED spot curing? As with many other advances in micro processing technology, UV-led spot curing is one more example of meticulous engineering precision resulting in fully controlled, aggressive yet reliable curing applications across many sectors. Considerable application of this technology can be realized when key parameters like intensity, dose, wavelength, and spot size are set and controlled adequately by the manufacturer. Visit UVET.