What is Laboratory UV Curing?

Laboratory UV curing is a process in which a material is subjected to ultraviolet (UV) light to polymerize or harden. It is normally applied in adhesive UV curing processes, resin UV curing systems, and polymer UV curing systems. In comparison to the traditional thermal curing techniques, UV curing is quicker, requires less energy, and curing processes are more accurate in UV, so it is suitable for sensitive materials like microelectronics, optical devices, and medical devices.

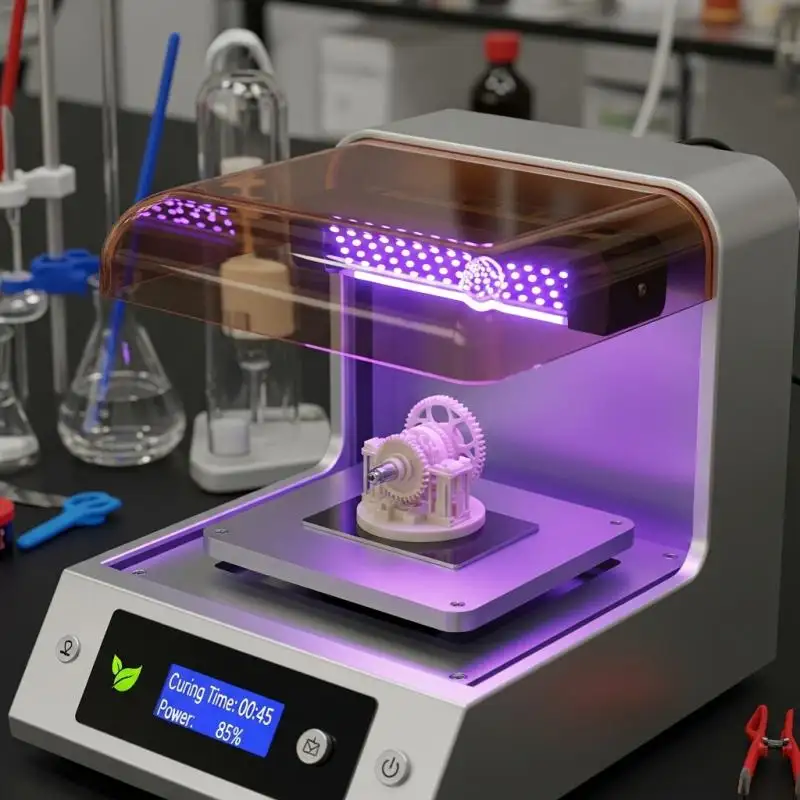

UV curing chambers and UV LED curing devices have moved towards controlled UV curing that can be used in the laboratory with precise control of UV exposure, low-heat generation, and controlled curing technology in laboratories.

Such Major Characteristics of Laboratory UV Curing Systems

Regulated UV Curing Technology

State-of-the-art systems offer digital UV curing control systems, which enable operators to change and set curing parameters that include UV wavelength curing, light intensity, and exposure time. This allows micro-level control of UV curing, which is necessary with high precision processes such as electronic parts curing or adhesive bonding in fragile substrates.

Quick and Efficient Energy Use

The UV LED curing technology can allow laboratories to attain fast curing cycles without high heat levels. This is a quick and dependable UV drying technology for lab tests, which enhances throughput and preserves the material. The economical laboratory UV system also saves on the cost of operation and the amount of environmental impact, which is now in line with the current trend in eco-friendly laboratories.

Precision UV Executing Machinery

Systems are designed with high-accuracy UV curing operations, and they give even curing on diverse materials like polymers, adhesives, and resins. UV curing systems of adhesives and UV LED curing for laboratory work guarantee uniformity of results in complicated or delicate systems.

Automation of UV Curing

Modern automated UV curing systems allow the laboratories to incorporate UV curing into production lines without problems. UV integration and smart UV curing automation in the laboratory production lines minimize human error, enhance reproducibility, and efficiency of the workflow.

Laboratory UV Curing uses

Adhesive and Resin Curing

UV adhesive curing equipment is commonly utilized by laboratories to bond together components in seconds in an industrial and research setting. The polymer and resin UV curing systems can be used in controlled curing technology in the laboratories, where adhesives and resins can reach their best strength without breaking the fragile substrates.

Curing of Electronic Components

Laboratories are able to cure delicate electronic parts with ease with micro-precision UV curing and high-intensity UV lamp systems. Laboratory microelectronics curing machines provide a high level of accuracy and consistency of the curing process without damaging delicate circuits and keeping them at their optimum functioning capability.

Medical and Optical Applications

In medical device labs, medical device lab UV curing solutions are important in curing adhesives and coatings on the surgical instruments used in surgery and implants, and diagnostic devices. High-precision UV curing system of adhesives is used in optical components such as lenses and sensors to guarantee their clarity, durability, and dimensional stability.

UV Curing Laboratory UV Advantages.

Precision and Consistency: Digital UV curing control systems allow laboratories to have a high-accuracy UV curing process, despite all the materials producing a similar result.

High Curing Cures: The UV LED curing technology offers high and efficient UV curing technology in laboratory tests, consuming much less time.

Energy Efficiency: UV curing systems that are efficient use less power and produce high-intensity light that is used to cure the item.

Green Operation: LED-based systems generate a low amount of heat, contain no mercury, and last a long time during their operations, which is why they are the best systems to be used in the laboratory to promote sustainability.

Multipurpose Uses: Adhesive and resin laboratory UV curing systems may be used with materials of various types, such as polymers, ceramics, and composites.

The benefits of UV LED Spot Curing Systems

The UV LED spot curing system is a special laboratory system that integrates fast UV curing technology with energy-saving use. Key benefits include:

High Performance and Low Heat: High capacity to cure on the micro-level with minimal heat emission, sensitive materials are also safeguarded.

Green Operation: The LED-based systems are eco-friendly, contain no mercury, and are conducive to long operation life.

Repeated Workflow Operability: UV curing is workflow-supported, enabling labs to automate curing operations and maximize throughput.

Precision and Adaptability: Appropriate for the curing of adhesives, polymers, and resins in a range of laboratory uses.

Cohen's combination with Contemporary Laboratory Processes

Current UV curing machines in the laboratory are made to be compatible with automated laboratory processes. UV curing systems can be easily integrated with laboratory processes and automation equipment, with the availability of laboratory automation systems and technology that optimizes laboratory processes.

Repeatability in Laboratory Results: Guarantees that laboratory results can be repeated.

Material Bonding Technology: Enhances the performance of adhesive and resin in challenging uses.

High-Speed UV Curing Equipment: Facilitates high-throughput laboratory activities.

Quality-Managed Processes: Digital interfaces enable keeping track of and making adjustments that provide high-precision UV curing procedures each time.

The Reason for Laboratory UV Curing?

Laboratories using UV curing systems that are investable in have the following advantages:

Precision Curing: Provides controlled and uniform curing of adhesives, polymers, and electronic components.

Time Saving: Cures faster than other traditional methods of curing.

Energy Savings: Reduces the amount of electricity used in the LED UV curing systems.

Sustainability: Promotes anti-environmental high-heat and mercury-free operation.

Versatility: Can be used over a variety of different laboratory applications, including medical, electronics, optical, and polymer laboratories.

To learn more, go to UVNDT to learn more about our line of UV curing equipment and technical materials.

Conclusion

Laboratory UV curing is a revolutionary technology for contemporary research and industrial laboratories. Through integration of controlled UV curing, LED UV curing, as well as automated UV curing, laboratories are able to realize high accuracy, energy saving, and fast curing.

The implementation of the laboratory UV curing systems will guarantee that the laboratories have quality-managed UV processes, streamline the production process, and have eco-friendly and sustainable operations. To get specifications and technical advice, go to UVET and see our large variety of precision UV curing systems.