What is LED Curing and how does it work?

- LED curing is a light-based curing technology that utilizes UV LED technology to initiate photochemical curing reactions in UV-sensitive materials like adhesives, inkjet, coating, and resins. The fundamental principle underlying the curing process is the phenomenon known as photo polymerization, where exposure of a material to a regulated UV wavelength emission reacts with photo-initiators in the material, resulting in the rapid cross-linking and hardening of the polymer.

- An LED UV curing system, unlike mercury lamps, uses a solid-state curing system, which produces a precise UV irradiation without the extreme heat, toxic substances, and extended warm-up periods that are characteristic of traditional UV curing.

Reasons behind the replacement of the traditional UV Curing by LED Curing Technology

The comparison between the LED curing and traditional UV curing shows clearly why industries are moving towards LED-based solutions.

The main benefits of Curing Technology.

- Instant on/off feature removes warm-up time.

- Thickness curing is used to protect delicate substrates.

- Curing that is efficient in terms of energy saves energy.

- LED UV curing is mercury-free, and therefore safer and greener.

- Regulated curing power enhances the uniformity of products.

- LEDs have long service lives, which reduces maintenance downtimes.

This efficiency, safety, and precision combine, thus making LED curing a better option to be used in high-performance production setups.

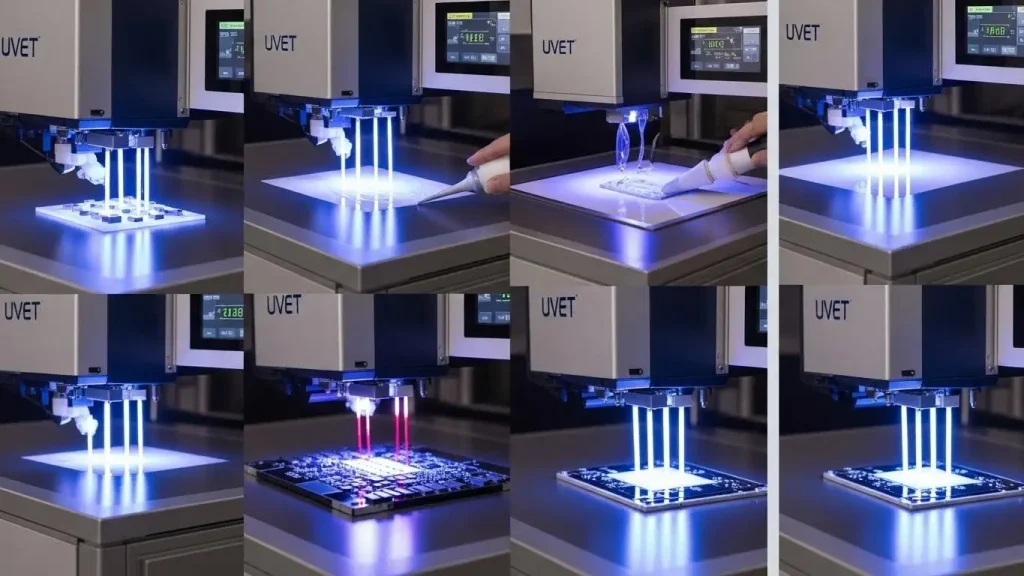

Basic Elements of the LED Curing System

A modern curing is designed to be precise, durable, and scalable. Key components include:

- LED lamp/ curing module.

- Optimized spectral distribution with UV LED array.

- Air- or water-cooled thermal management system

- High-tech curing control interface.

- Design or structure of the curing chamber or open-area structure.

Combined, these factors provide consistency in the distribution of light, optical irradiance, and even the radiant intensity in each cycle.

LED Curing Machines made in industries

The use of high-performance LED curing equipment has become very common in industries where precision and repeatability are highly needed. The technology can be easily adjusted to a production requirement, whether it is part of a fully automated curing system, conveyor-based system, or a handheld curing device.

Industrial curing solutions with industrial LED are chosen by industries as they allow:

- Rapid polymer curing

- Precision curing processes

- Optimized exposure time

- Improved product quality

- Reduced operational costs

LED Curing Application in Industry

- LED Curing of Adhesives and Bonding

In the case of adhesive bonding, curing provides immediate strength without the use of heat. This is particularly useful in electronics encapsulation, optics, and the curing of medical devices.

- LED Curing of Coatings and Inks

The concept of curing coatings and inks provides a good hardening of surfaces at a smooth surface, scratch resistance, and uniform quality of the finish, hence it is perfect for curing of printing and packaging.

- Resins and 3D printing LED Curing.

The ability of resin cross-linking and 3D printing resin curing to have control over the wavelength allows great cure depth control and accuracy in dimensions.

- LED Curing of Electronic and Medical Products

It is used in dental composite curing and micro-assembly since it offers clean, low-heat, and safe curing environments and guards delicate components.

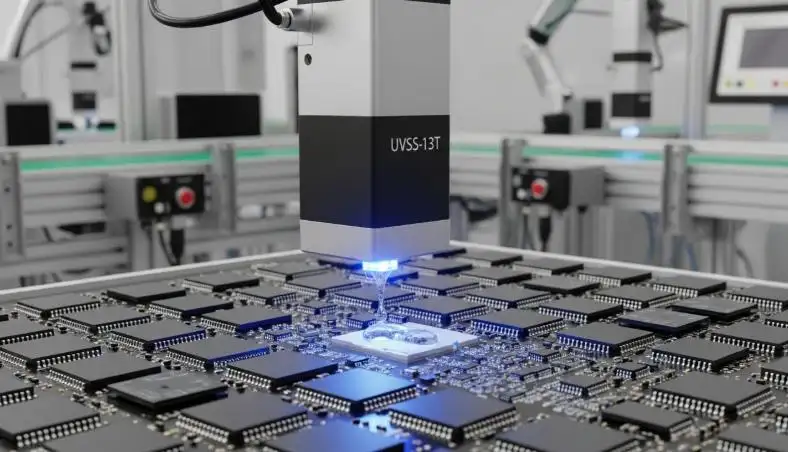

Spotlight: UV LED Curing Device- Model UVSS-13T

The UV Curing Device, Model UVSS-13T, is one of the best examples of the new technology of curing and can be purchased at professional suppliers such as UVET.

The Ph50mm diameter ring-shaped design of this industrial grade, compact, but powerful curing system provides highly uniform UV irradiation over a coverage area of Ph25mm to Ph50mm to provide repeatable and precise curing of relatively complex assemblies.

Technology, Technology Specifications, and Design

- Area of targeted irradiation: Ph25-Ph50mm.

- Wavelengths: 365nm, 385nm, 395nm, 405nm.

- High-intensity LED treatment output.

- Thermal management using water cooling.

- Instant on/off operation

- User-friendly interface

- Cold heat production of delicate materials.

The UV curing machine is superior in electronics assembly, optics alignment, medical device bonding, and optoelectronics production.

Benefits of the UVSS-13T to Precision Manufacturing

The system has applications in electronics manufacturing as an adhesive bonding curing system, sealing system, and micro-assembly system where uniform cure performance and control over cure are mandated.

It is a safe procedure used in attaching components such as catheters and diagnostic housings without damaging heat-sensitive parts. In optoelectronic applications, it provides proper lens position placement and permanent sensor bonding, aided by a homogeneous light distribution and constant UV output.

It has high repeatability curing as it has a beam stability and is suited to automated and repeatable processes in manufacturing.

- High-end LED Curing Control

The enhancement of the efficiency of modern curing is based on data optimization. Manufacturers fine-tune:

- Exposure time optimization

- Wavelength matching

- Curing kinetics analysis

- Cure depth control

This will provide the best photo polymerization and avoid over-curing and degradation of the materials.

- Sustainability, Compliance, and Energy Efficiency

Green curing is no longer a choice; it is a competitive edge. This equipment offers:

- Low power consumption

- Lower carbon footprint curing.

- Curing systems that are compliant with RoHS.

- Curtis-free curing solutions.

- Environmentally friendly production.

These advantages are consistent with the international environmental standards and reduce the overall cost of operation.

Selection of the Optimal LED Curing Solution

Buyers need to consider that when selling curing systems:

- Application requirements

- UV wavelength output required.

- Irradiation area size

- Combination with automated systems.

Conclusion:

The development of LED curing can be seen as a wider trend of more intelligent, greener, and more efficient production. These curing systems enable industries to deliver high quality in production processes through benefits that include faster production cycles and increased control over them, thus attaining sustainability targets. With the current development of next-generation curing technology, companies investing in high-performance curing equipment will place themselves in the path of long-term operational excellence and competitive expansion. Visit UVET.