What is LED Curing Technology?

Fundamentally, an LED curing machine is a solid-state curing system that produces ultraviolet energy, which is used to initiate a light-activated curing process. This is the starting point of photopolymer curing, where UV-reactive adhesives, inks, coatings, or resins are quickly polymerized and hardened.

- In comparison to the mercury-based lamps, which take time to warm up and produce unnecessary infrared heat, the UV LED curing equipment offers immediate on off curing. This leads to improved process control, reduced use of energy, and a safe working environment.

- The current systems employ accurate UV wavelengths that are usually 365nm, 385nm, 395nm, and 405nm, enabling manufacturers to determine the best spectral output with particular materials. The outcome is an accelerated curing process, uniform quality, and high bond strength.

LED Curing Machine: Guide to UV LED Curing Technology of high efficiency

- In the modern world of rapid manufacturing, accuracy, speed, and dependability are more of a concern than ever. In electronics and medical equipment, printing, packaging, and other manufacturers are always seeking curing systems that provide steady quality at minimum operating costs. The LED curing machine is the way to go here because it is a smart and high-tech solution for the future.

- The LED curing system has revolutionized the industry by influencing the manner in which industries handle ultraviolet light curing due to advanced LED-based technology used in the system. In contrast to the old type UV arc lamp, the new LED UV curing machine is energy-saving, fast-starting, low-heat, and high-curing control. Freestanding LED curing machine, LED curing equipment is used as an industrial LED curing machine in high-volume production or as an automatic LED curing machine in smart manufacturing lines.

How LED Curing Machines Work?

The principle of operation of an LED curing machine is very easy but technologically developed. Intense arrays of LEDs produce ultraviolet light at a specific wavelength. Upon uptake of this UV energy on a UV-reactive material, photo initiators in the material are activated, initiating the reaction of polymerization.

The important technical parameters include:

- Optical intensity (mW/cm2)

- Radiant energy (J/cm2)

- Exposure time control

- Cure depth

By employing even distribution of light and maximum configuration of LED arrays, the new LED curing machines do away with most of the problems known to many rival UV curing machines, such as shadowing or under-curing that were normally experienced on older UV systems.

Technical merits of LED Curing Machines

The high-efficiency LED curing machine has become so popular due to its technical superiority in various parameters.

- Accurate Wavelength Adjustment

A variable wavelength LED curing machine enables the manufacturer to choose the most efficient wavelength of 365nm deep curing, 385nm balanced performance, 395nm fast surface cure, or 405nm coating for a special purpose.

- High Optical Performance

Modern designs have steadily delivered an increase in UV intensity up to 1500-1800mW/cm2, and the LED curing machines offer powerful and stable output with high optical efficiency and constant light output during tens of thousands of hours.

- High-tech Thermal Control

Thermal management systems such as air-cooled LED modules and water-cooled LED systems are efficient in maintaining a constant performance over extended production cycles and low heat emission of sensitive components.

- Long Service Life

Normal LED lives are between 20,000 and 50,000 hours, which severely minimizes downtime, service, and maintenance expenses as well as frequency of replacement.

Comparison of the LED Curing Machine and Mercury UV Curing

Comparing the LED curing machine to mercury UV curing, it is obvious that the LED technology has certain advantages.

- Conventional mercury lamps use more energy, produce ozone, need a warm-up time, and also deteriorate with time. On the contrary, LED systems are curing technology that is free of mercury, ozone-free, and environmentally friendly. They give predictable performance at the very start through to the end, and offer an excellent, cost-efficient curing technology with a reduced total cost of ownership.

- LED curing machines are a great fit as a solution to current sustainability ambitions since they are a classic UV lamp replacement and a better substitute to UV arc lamps.

LED Curing Machines Application in Industries

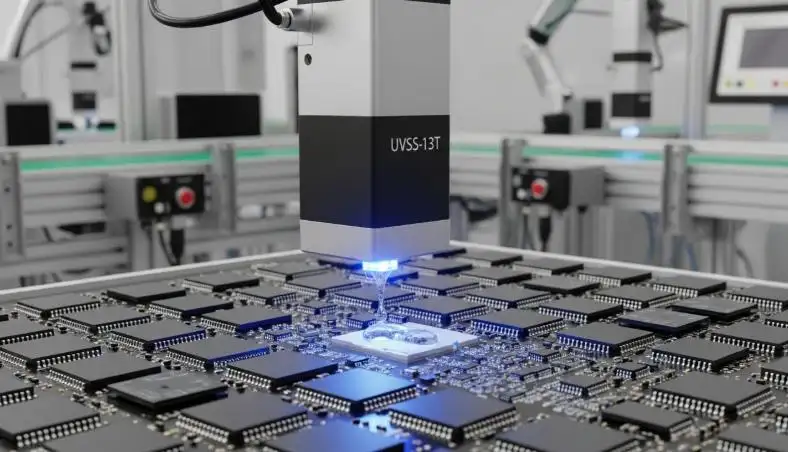

- Electronics and PCB Manufacturing

The PCB conformal coating and electronic component curing LED curing machine is a machine that provides high-accuracy PCB conformal coating and electronic component curing, which is free of thermal damage.

- Printing and Packaging

Fast-curing LED machines are used in the printing industry to provide instant ink curing, better quality of print, and also less time to produce prints. Automation Packaging lines enjoy the advantages of inline production curing and conveyor automation.

- Medical Devices

In the medical device bonding, LED curing machines offer clean and controlled curing that is in line with high standards of safety and workplace regulations.

- Automotive Industry

The LED systems are used in automotive curing of coats to provide a uniform finish, high adhesion, and durability of the components that are subjected to extreme environmental conditions.

- Adhesives, Coatings, and Resins

Regardless of the hardening of the resin, adhesive bonding, or coating polymerization, LED curing machines provide them with the accuracy of cure depth and consistent outcomes.

Why UV LED Flood Curing Machine?

- The distinction of this system is the balance of power, flexibility, and efficiency. The huge curing space minimizes the time of processing since it cures multiple elements at once. Its adjustable wavelengths provide a high degree of compatibility with various materials, which provide the maximum cure depth and bond strength.

- Having fast activation, low-energy use, and quality curing, this machine represents the essence of the advantages of LED technology and provides the reliability of an industrial machine.

- This system can also be combined with other existing production lines by manufacturers who want a turnkey UV curing system, or can also be operated as an independent workstation.

Sustainability, Safety, and Compliance

- The current industries are highly focused on sustainability, and the LED curing machines facilitate the transition. The systems adhere to the RoHS standards, minimize carbon emissions, and eliminate the dangerous substances present in the older UV systems.

- LED curing machines also provide a cleaner, safer production environment by providing lower power usage, extended lifespan, and reduced heat, which leads to the reduction of operational costs.

Conclusion

The LED curing machine is not a mere substitute for the conventional UV systems, but it is the new trend of modern production. These machines enable a company with enhanced UV LED curing technology, effective control, and unrivaled efficiency to produce a high-quality, high-throughput, and sustainable production. Be it to purchase LED curing machines, seek a tailored LED curing system, or upgrade an already existing curing line, LED technology can provide the performance, reliability, and scalability that the future demand of production will require. For details, visit UVET.