LED UV Curing Systems vs. Traditional Mercury UV Lamps: Real Benefits

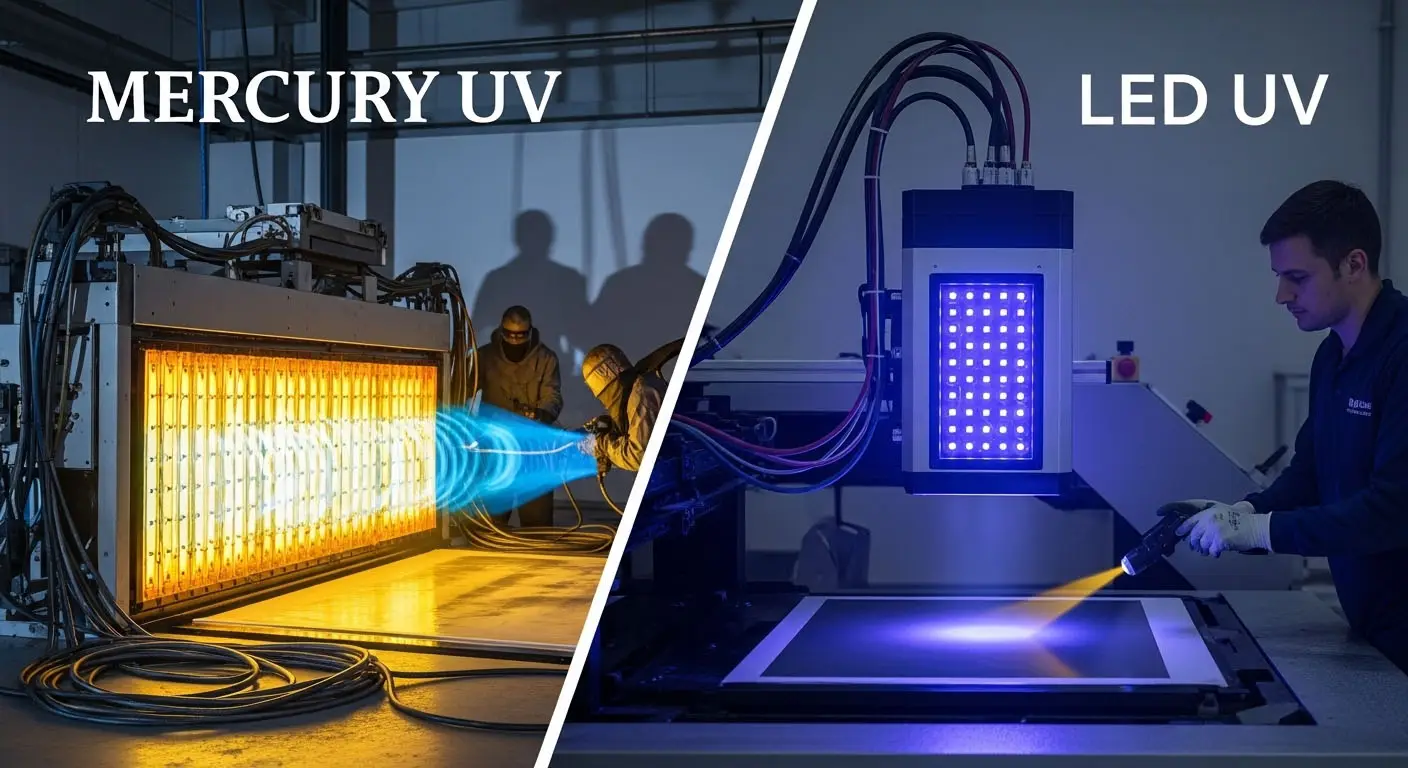

When comparing LED UV curing systems to traditional mercury UV lamps, several significant advantages emerge that explain why many industries are transitioning to LED technology:

Energy Efficiency and Cost Savings

LED UV systems consume significantly less power than mercury lamps, resulting in lower operational costs over time.LINKEDIN While the initial investment for LED systems is typically higher, the long-term savings in energy, maintenance, and replacement parts often offset this cost.LENCOLO37

Longer Operational Lifespan

LED systems offer dramatically longer service life—often exceeding 10,000 hours—compared to mercury lamps that typically require replacement after just 1,000-2,000 hours.LENCOLO37 This translates to less downtime and lower maintenance costs.

Instant On/Off Capability

Unlike mercury lamps that require warm-up periods, LED systems provide instant on/off functionality with no warm-up or cooldown cycles.LINKEDIN This enables precise control over UV exposure and improves production efficiency, especially in processes requiring rapid cycling.

Environmental and Safety Benefits

LED systems are mercury-free and produce no ozone, making them more environmentally friendly and safer to operate.IST-UV As environmental regulations like the Minamata Convention increasingly restrict mercury use, LED technology offers a compliant alternative that eliminates hazardous waste concerns.LENCOLO37

Reduced Heat Transfer

LED systems generate less heat and provide lower penetration of heat into substrates.IST-UV This makes them ideal for temperature-sensitive materials that might warp or degrade under the higher heat output of mercury lamps.

Targeted Wavelength Output

While mercury lamps emit a broad spectrum (UVA to UVC), LED systems provide specific wavelengths—typically 365nm, 385nm, 395nm, or 405nm.LENCOLO37 This targeted emission can enhance process efficiency when matched with compatible formulations.

Compact Design and Flexibility

LED systems offer more compact designs and can be configured with zone circuits for greater application flexibility.IST-UV

Considerations When Choosing

Despite LED advantages, mercury lamps remain valuable in certain applications:

- When broad-spectrum curing is required for traditional photoinitiators

- For deeper curing of thick or highly pigmented materials

- When working with legacy UV formulations not optimized for LED wavelengths

- In situations where lower initial investment is prioritized over long-term efficiencyLENCOLO37

The optimal choice ultimately depends on your specific application requirements, production volume, and sustainability goals.