Advanced UV Technology based on Improving Quality Control in the industry

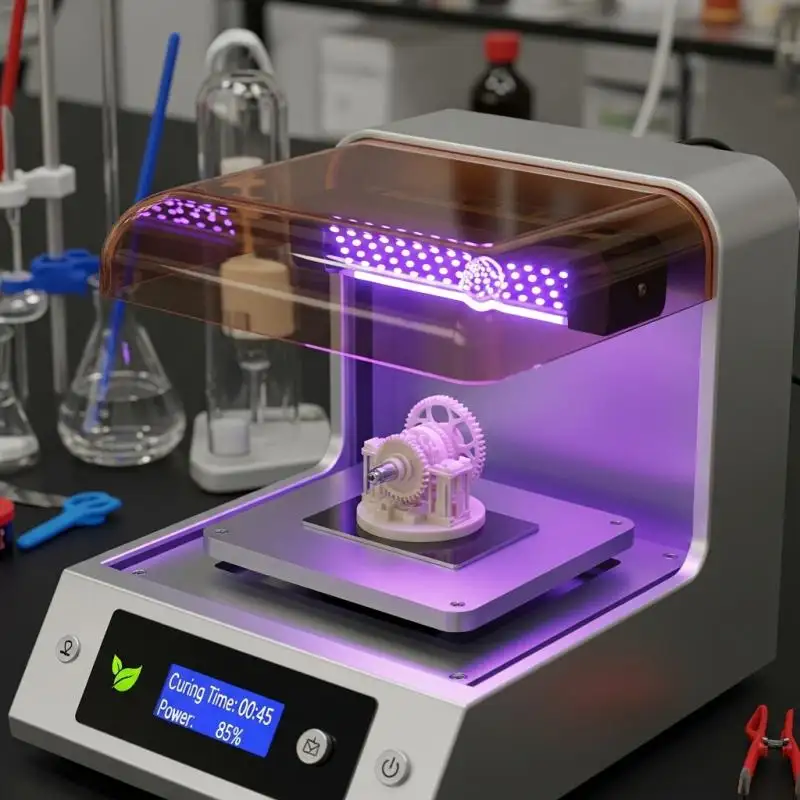

The use of LED UV inspection has become a fundamental method of product quality, safety, and reliability assurance in the current industrial and commercial settings. In contrast to the conventional inspection modes, the UV LED inspection is an accurate, efficient, and non-destructive testing (NDT) method, through which industries can identify the presence of flaws, defects, and inconsistencies at a fast and accurate rate.

In the range of laboratory testing to large-scale manufacturing, LED UV light inspection, and UV LED technology, inspection is crucial in quality assurance, fabrication of surface flaws, and industrial repair. The development of LED inspection lamps and mobile systems presents flexibility to the professionals in that they can do the inspection in almost any environment.

What is LED UV Inspection?

It is a procedure whereby the inspection process employs UV LED lighting to light up surfaces, materials, and parts so as to identify defects that cannot be seen with normal lighting conditions. The defects can be in the form of cracks, scratches, voids, or surface contaminants that can affect the integrity of products.

UV LED inspection lamps produce ultraviolet light of precise wavelengths, usually in the range of 365nm, which interacts with substances or fluorescent labels to identify defects. The LED UV lamp inspection method is particularly appreciated in industrial UV inspection, non-destructive testing, and quality control uses because it does not destroy the objects being tested.

How it is Works

The ability to carry out LED UV inspection would entail the ability to understand how UV light interacts with surfaces to be inspected.

UV Light: The UV light inspection lamp is a concentrated UV light that is emitted over the surface by the LED.

Fluorescence Reaction: Lots of defects and contaminants can fluoresce when subjected to UV radiation, so that they can be observed.

Detection and Documentation: These glowing reactions are used by the Inspectors to find the defects, quantify their magnitude, and record the results against which quality inspection will be conducted.

The process is made very efficient by employing the UV LED inspection systems. The advantage of the LED-based system is that, unlike the conventional mercury UV lamps, the systems produce high-intensity, energy-saving, portable, durable, and safer light.

The benefits of LED UV Inspection

Implementation of LED UV inspection entails several benefits as compared to the traditional practices:

High Precision: Identifies micro-cracks, surface flaws, and hidden defects that might be overlooked during a regular check-up.

Non-Destructive Testing (NDT): Tests components to make sure they are not damaged.

Energy Saving: The lamps with LED use less electricity and produce little heat.

Portability: Mobile LED inspection lamps can be used to conduct inspections in the field, laboratory, or industry.

Sturdy and Long-lasting: LED lamps last longer than ordinary bulbs.

Weaknesses: Two variants are not compatible with all applications; manufacturing, packaging, electronics, and lab research can be used, but not all applications.

Applications

Applications in many industries: LED inspection lamps and systems are applied in a wide variety of industries:

Aerospace and Automotive: The hairline cracks in important parts and components are detected.

Electronics: Assuring the integrity of solder joints, circuit boards, and electronic assemblies.

Manufacturing: Inspection of manufacturing lines, detection of surface defects or contamination.

Packaging Industry: Checking labels, surfaces of coatings, printed materials, and other surfaces to check for defects or imperfections.

Laboratories: Conducting studies and experiments in areas of precision and reliability.

The industries that implement UV LED non-destructive testing record increased productivity, cut down on wastes and ensure that they observe high safety and quality standards.

Introduction of the UV LED Inspection Light PGS150A

PGS150A UV LED inspection light is the most advanced in UV inspection technology using LED. It is portable and fixed to be used both handheld and with fixed usage, offering precision, intensity, and flexibility to be used in the work of a professional.

Key Features:

Ideal Broad Area: This one will offer a 7-inch (17cm) UV beam with a coverage of 15 inches (38cm) of coverage to conduct expansive checks.

Intense UV: 2,000 uW/cm2 minimum to provide consistent flaw detection on surfaces.

Optical Glass Lens: The lens offers a constant and uniform UV beam with low transmittance loss over time.

Dual Power: Portable or continuous use, rechargeable Li-ion battery or 100-240 V AC adaptor.

Fanless Cooling System: Noise-free mechanical cooling can guarantee safe, efficient machine operation.

Why the PGS150A UV LED Inspection Light?

The PGS150A lamp is made to match the needs of professionals who require accuracy as well as convenience:

High-Intensity UV Production: Ensures an accurate image of defects on hard-to-detect surfaces.

Wide Beam Coverage: Makes sure that extensive coverage is covered without the quality of detail being lost.

Durable Design: The optical glass lens has a consistent UV emission during extended use.

Flexibility: Supports both handheld mobility and fixed applications and is flexible enough to fit into different inspection applications.

Efficient and Quiet Operation: Fanless mechanical cooling ensures that noise is quieted and that the operating temperature is maintained at optimum levels.

Optimization of LED UV Inspection

To achieve the most accurate outcomes of LED UV inspection, the professionals must take into account:

UV Intensity: Set the intensity so that defects are correctly seen.

Beam Coverage: A lamp such as PGS150A covering 7 inches can be used to do a wide or IT inspection.

Wavelength Selection: Select lamps that are optimized for the materials and fluorescent markers under inspection.

Portable vs Fixed Operation: Decision on whether handheld flexibility is essential or stationary inspection is essential.

Safety Precautions: Protective equipment must be used to reduce UV exposure.

An optimized inspection process will minimize the number of errors, enhance efficiency, and meet the quality standards.

Future of LED Inspection

The future of LED UV inspection is promising, and innovations have been made with an emphasis on:

- More Intensity LEDs to detect defects faster.

- Mobile devices are used to conduct inspections on-site in isolated or limited areas.

- Real-time quality control, Automated Systems.

- Green Solutions: The reduction of environmental impact.

- Greater Durability and Optical Accuracy in long time application.

Firms that also adopt UV LED inspection technology will have greater efficiency, quality assurance, and safety of operations.

Conclusion

The use of LED UV inspection has transformed the current quality control to be fast, accurate, and safe. In various applications, such as electronics and automotive, packaging, and laboratories, industries can obtain quality, reliability, high-performance and quality of defects with PGS150A UV LED inspection light.

To learn more about LED UV inspection lamps and solutions in industrial, laboratory, and commercial applications, contact UVET to discover the entire selection of UV LED inspection equipment and professional inspection solutions.