UV LED for Medical Devices: The Ultimate Guide 2025

UV LED for medical devices denotes a photochemical process in which light-emitting diodes (LEDs) emit ultraviolet (UV) rays of light at specific frequencies. In the medical field, this technology is used for two primary reasons:

- UVC Sterilization (275nm)

UVC LEDs at 275 nanometers can inactivate viruses, bacteria, and other microorganisms from the external surfaces of surgical instruments, medical tools, and laboratory equipment. UVC LED sterilization does not use heat or chemicals, unlike traditional methods, which makes it non-toxic, instantaneous, and residue-free, resulting in enhanced sterilization effectiveness. This renders it safe for sensitive environments such as operating rooms or cleanrooms.

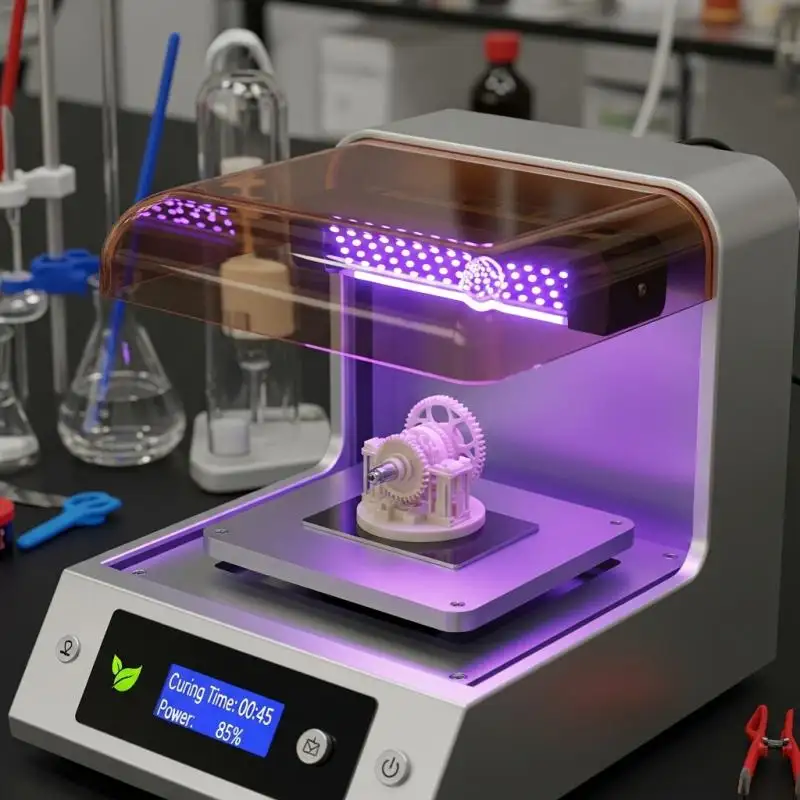

- Biocompatible Adhesive Curing (365nm)

Medical-grade adhesives used for bonding surgical tools, catheters, syringes, and implants require curing without losing biocompatibility. Bonds formed using 365-nanometer UV LED systems emit supremely hazardous by-products during curing, thus ensuring biocompatibility.

What Makes UV LED Curing Significant in Medical Device Manufacturing?

Precision, cleanliness, and reliability are essential in the healthcare industry, which is highly regulated. Here’s what makes UV LED curing important:

- Minimal Heat

Traditional curing and sterilization methods generate considerable heat that can easily damage plastics, polymers, and delicate electronic parts within medical devices. Unlike other methods, UV LED curing preserves sensitive structures and devices because its curing processes maintain low temperatures.

- None Solvent Sterilization

UVC LED sterilization employs no alcohols, peroxides, or autoclaving, thus increasing the finesse of the instruments and reducing cross-contamination risks. This makes it helpful for single-use medical devices, multi-use tools, and even implantable equipment.

- Moisture & Weather Resistant

Implantable surgical instruments and diagnostic tools that function both outside and inside the human body can change their surgical environment and need protective coatings and adhesives that are shielded from extreme temperature changes, humidity, and chemicals.

Tactical Use of UV LED Curing Technology in Medicine

Today, curing systems facilitate the production, sterilization, and assembly of medical devices. This is their most common application in the industry.

1. Surgical Instruments

Heat illumination (UV LED cure) achieves sterility for scalpels, forceps, and scissors. This is accomplished with assembly or coat adhesives that are overly cured during manufacturing without amputation of material softness.

2. Implantable Devices

Sealing of body implants like pacemakers, dental implant dentures, or any joint replaceable parts is done with the aid of UV curing. Biologically compatible sealant (which is biocompatible) that retains body fluids, withstands temperature shifts, mechanical strain, and encapsulation. This assists in averting risky dangers that come with germs, as well as improving the enduring quality of the product.

3. Diagnostic Tools & Test Kits

The diagnostic tools are nowadays shifting towards portability, thus creating the need for portable test kits. These days, there is a need ‘UV LED-cured’ clear strip adhesive bonding and assembling under sterile conditions. In bonded joints with clear control over the time and thickness of deep curing. UV LED curing provides time and depth-controlled bonds that are clean from outer impurities.

4. Catheters and Tubing

The medical-grade tubing and catheters demand a high level of precision for thermal bonding. Bonding techniques using UV LEDs result in strong bonds to flexible binders such as silicone and PVC, which are made soft and flexible without being disturbed or destroyed.

5. Wearable Medical Devices

Newly designed smart wearable technology, such as fitness trackers and smart insulin pumps, makes use of UV LED technology, which provides low-temperature cures to adhesives and epoxy encapsulates intended for protecting the electronics.

Practical Success of UV LED Solutions

Survey findings among our clients were overwhelmingly positive concerning UV LED curing systems within the medical devices sector. These are the projects we undertake:

- A leading surgical instruments manufacturer augmented UVC sterilization cycle times by 70% when UVC LEDs were added to the wrapping machine.

- An enduring implant developer improved the accuracy of bonds cured with 365nm light and reduced the volume of adhesive used, increasing the strength of the finished device.

- A dominant brand in diagnostics created compact UV LED curing heads for installation in modular test kit lines, improving daily output by 40%.

What distinguishes us?

Leading the UV LED curing solutions market has allowed us to establish a strong reputation with Medical Device Manufacturers Trust. This stems from over a decade of experience in the field.

- Advanced cross-industry understanding

Custom medical devices and their related manufacturing processes have defined our business focus over the last 10 years. This was achieved alongside numerous OEM, hospital, and cleanroom manufacturer partnerships.

- Certified Engineering The Quality Mark

Medical professionals understand the importance of working with sensitive instruments and are required to adhere to strict product standards, including CE, RoHS, ISO, and others, ensuring safe manufacturing practices.

- Tailored Technical Support

Our team offers support starting from product development, system integration, and after-sales maintenance. In surgery as well as in medical manufacturing, precision, uptime, and zero downtime are imperative.

LED UV Technology: Effective, Clean, and Dependable

The same goes for all UVET equipment, our curing systems are non-mercuric and therefore cleaner than their counterparts. Other system highlights include:

• Energy Efficient: Uses up to 70% less energy than standard UV systems.

• Operational Endurance: Can be used for over 20,000 hours.

• Instant Off/on Controls: No cool-down or warm-up time is required.

• Compact Resizing: Modular cleanrooms and production lines have adjustable and easy fitment.

Custom Manufactured UV LED for Every Medical Requirement

At UVET, we offer exclusivity under OEM/ODM at the prototyping phase till bulk production according to demand for medical manufacturing, which includes but is not limited to:

• Coating and adhesive curing using UV LED.

• Labeling and packaging for medical use, UV printing.

• UVC module sterilization of instruments and environments.

• Integration of non-destructive testing (MT/PT).

From wearable health monitors to hospital-grade and implanted devices, UVET engineers work collaboratively with you through every stage for design integration to optimization for safety, speed, and reliability.

Conclusion

The health care industry UV LED for Medical Devices is revolutionizing the methods of device sterilization and component bonding. It allows for the manufacturing of safer products with improved results owing to low thermal impact, great precision, and eco-friendliness. When you partner with UVET, you work with a technology pioneer who comprehensively addresses the issues in medical production with customized, ready-made, and guaranteed solutions.