What are Modular UV Systems?

A modular UV curing system is a network of connected UV light modules that are created to be used in industrial-scale curing. These systems integrate scalable UV curing technology with LED-based UV modules, which allows manufacturers to tailor the curing footprint to their production requirements.

The major characteristics of a modular UV system are:

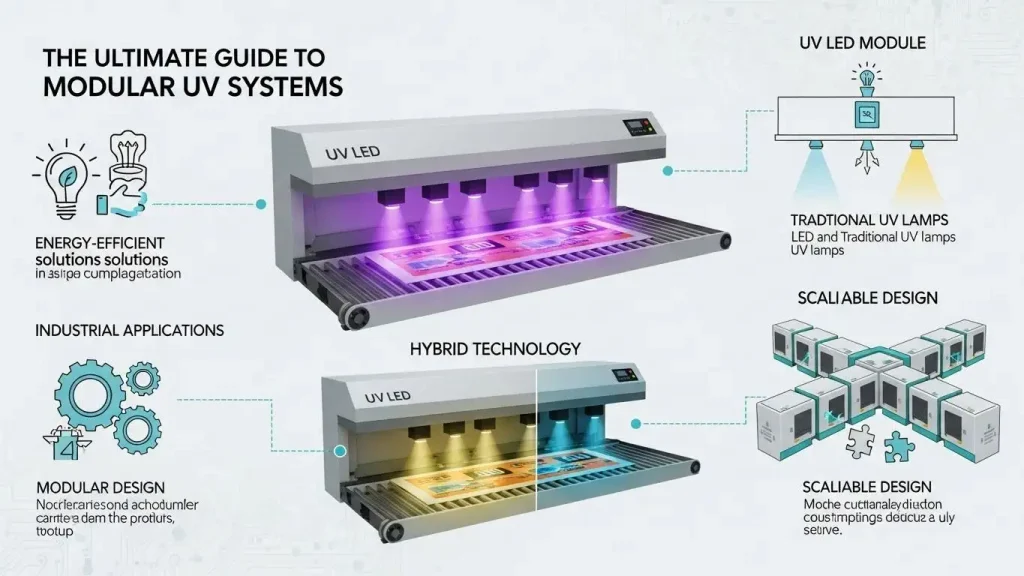

- Scalable and Modular Design: Modules may be stacked or mounted next to each other to create user-configured rectangles of illumination, which can adjust to varying production lines.

- Adjustable Wavelength UV Curing: Multi-wavelength (365nm, 385nm, 395nm, 405nm): Changeable wavelengths can be adjusted to match the material absorption spectrum.

- Constant UV Energy Distribution: Assures constant curing production and reduces incomplete coating.

- Smart Control Interfaces: Allows PWM dimming, RS-485/RS232 communications, and PLC integration to provide a fully automated industrial process.

- Good Cooling Systems: Water or air-cooled modules have a stable thermal control that is long-term reliable.

Such innovative characteristics make the modular UV system suitable for use where high precision UV curing, fast production cycles, and economical performance of UV curing are needed.

How Modular UV Systems Work?

The modular UV curing process is based on the concept of UV radiation curing, in which the ultraviolet light activates the process of cross-linking and curing of resin in the coating, adhesives, and ink. As compared to traditional heat curing, UV curing is rapid, energy-saving, and can cure at normal temperatures.

The curing process should include:

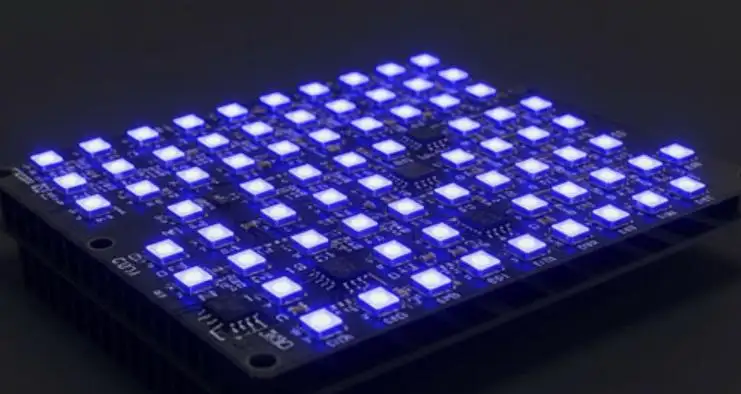

- UV modules based on LED: Produce specific wavelengths to cure.

- Modular curing architecture: It enables the system to be expanded or modified based on the size of production.

- UV curing thermal management: The cooling with water or air ensures stability in the performance of the long runs.

- Constant distribution of the UV energy: Eliminates over-curing or under-curing and defect-free modular UV curing.

With several modules combined together, industries can use flexible curing lines that can be adapted to various substrates such as metal, plastic, and medical-grade.

Efficiencies of Industrial Modular UV Systems

- Flexibility and Scalability

These UV systems are able to grow or reduce depending on the needs of the production. Regardless of PCB exposure, ink curing, or coating, manufacturers will be able to customize the setup to their needs.

- Great Accuracy and consistency

These systems offer even energy distribution, accuracy in UV curing, and intensity, which goes a long way to minimize defects in curing and enhance the quality of production.

- Energy Efficiency

The UV LED modular systems use less power as compared to the traditional UV lamps, which saves on the energy expenditure and still have a quick drying time.

- Reduced Production Time

High throughput and quality fast modular UV curing solutions allow short curing times, which facilitate high throughput production without compromising quality.

- Integration and Automation

The integration of a single-line modular UV system is easily integrated with automated lines using smart control interfaces and PLC-compatible designs.

- Life and thought durability.

High cooling systems and modular design guarantee long operation life and minimum maintenance.

The Technology of Modular UV Systems

The modern UV modular curing systems consist of a balanced combination of various advanced technologies that provide high-quality and accurate results:

- UV LED Modular Curing

LED-based modules can turn on and off instantly, have wavelengths that can be tuned, and long life, which can be achieved by using energy-saving UV curing with low heat emission.

- Hybrid Modular UV Curing Technology

UV LEDs used with conventional lamps or infrared sources can be combined to improve penetration and curing of thick coatings and complicated geometries.

- Adjustable UV System Wavelength

The intrinsic variability of UV output is enabled by multi-wavelength designs that enable manufacturers to adjust the UV output to fit the absorption characteristics of ink, adhesives, or coatings, resulting in optimal quality of curing and surface finish.

- Water cooling UV Curing Modular

Active water cooling ensures thermal stability, minimizes heat stress to delicate substrates, and ensures stable curing results in all modules.

Common Uses of Modular UV Systems

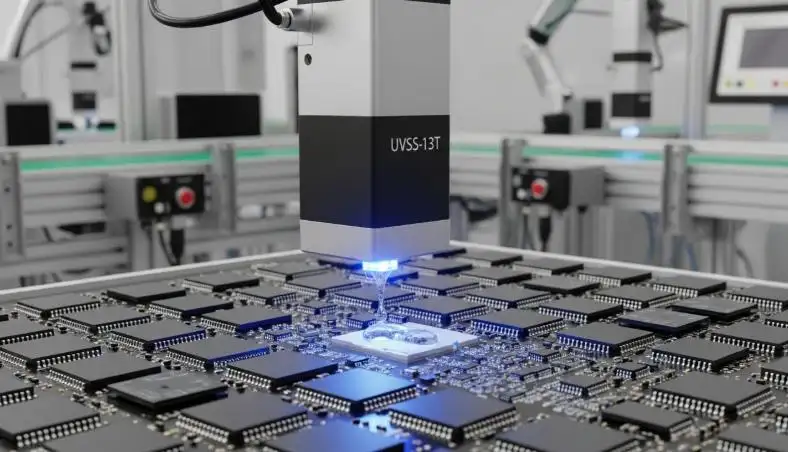

- Electronics Assembly

Electronics assembly UV curing must be precise and repeatable. Modular systems provide consistency in energy distribution that guarantees flawless modular UV curing of the PCBs, optical devices, and semiconductor components.

- Medical Devices

High-precision UV curing that uses minimal heat is advantageous for sterilization and curing of medical components. Modular systems provide uniform outcomes in sterilizing medical surfaces as well as disinfecting equipment.

- Automotive Coatings

Automotive Coating is used in automotive coating where a uniform film thickness, adhesion, and abrasion resistance are required. Scalable and flexible production lines are made possible by modular systems.

- Printing and Packaging

Flexographic or inkjet printing needs UV curing and fast curing solutions with use of UV curing. UV curing systems. Modular UV curing systems enable customization of modular UV curing solutions to large and small print areas.

- Optical Bonding

Adhesives need to be uniformly cured in high-precision optics. Modular UV curing provides a high degree of uniformity without harming heat-sensitive optical parts.

Characteristics that make Modular UV Systems unique

- High Blanking Ratio: Reduces the light spillage, which gives sharp edges and accurate curing on the exposed areas.

- Multi-Wavelength: 365nm, 385nm, 395nm, or 405nm wavelengths are optional and selected at the corresponding material response curves.

- Smart Control Interface: PWM dimming and PLC interfacing are accommodating completely automated industries.

- Efficient Cooling Systems: Air or water cooling guarantees a long-term stability of the operations.

- Modular and Scalable Design: Allows daisy-chaining and side-by-side installation of custom lighting areas.

Optimization of Modular UV Curing

Curing defects can also be experienced even with high systems, provided that process variables are not optimized. The typical problems consist of the fact that modular systems do not cure, there is uneven film formation, and under-cured coating.

Optimization can be done using best practices, which involve:

- Periodic adjustment of UV intensity and wavelength.

- Active cooling and thermal monitoring.

- Dwell time and stable location of modules are controlled.

- Programmability with automated modular UV curing systems to guarantee uniformity in processes.

Conclusion

A modular UV system is not merely a machine- it is a key instrument that brings about accuracy, effectiveness, and dependability in industrial operations. To the businesses that need to improve the quality of production, process reliability, a modular system is a choice that incorporates both technological innovation and operational excellence. Presentation of the latest products, technical specifications, and industrial solutions in UVET.