What are OEM UV Solutions?

OEM UV solutions are systems ascribed to a certain level of specialization and are defined by their purpose, formatted specifically for original equipment manufacturers (OEMs) as off-the-shelf solutions do not meet the requirements of all users. They are intended to work with the machinery and processes of a business; hence, they are not fully configurable and tailored to every customer's needs.

Use Case: Imagine a tailor who crafts garments for its customers; UVs are designed with exact specifications–desired wavelength, dimension, power output, and others. Such systems may consist of:

- OEM UV curing systems

- OEM UV LED modules

- Custom UV disinfection units

- Embedded UV light assemblies

- Compact and modular UV platforms

Our vision on seamless high-efficiency UV system integrations into various OEM products, such as curing machines and inspection tools, drives innovation at our Firm, UVET.

What Custom UV Solutions is the Best Choice?

OEMs need more flexibility. A generic UV lamp does not work for situational curing times, energy usage, and spatial constraints. This is where custom UV solutions are advantageous. Here’s why custom is better:

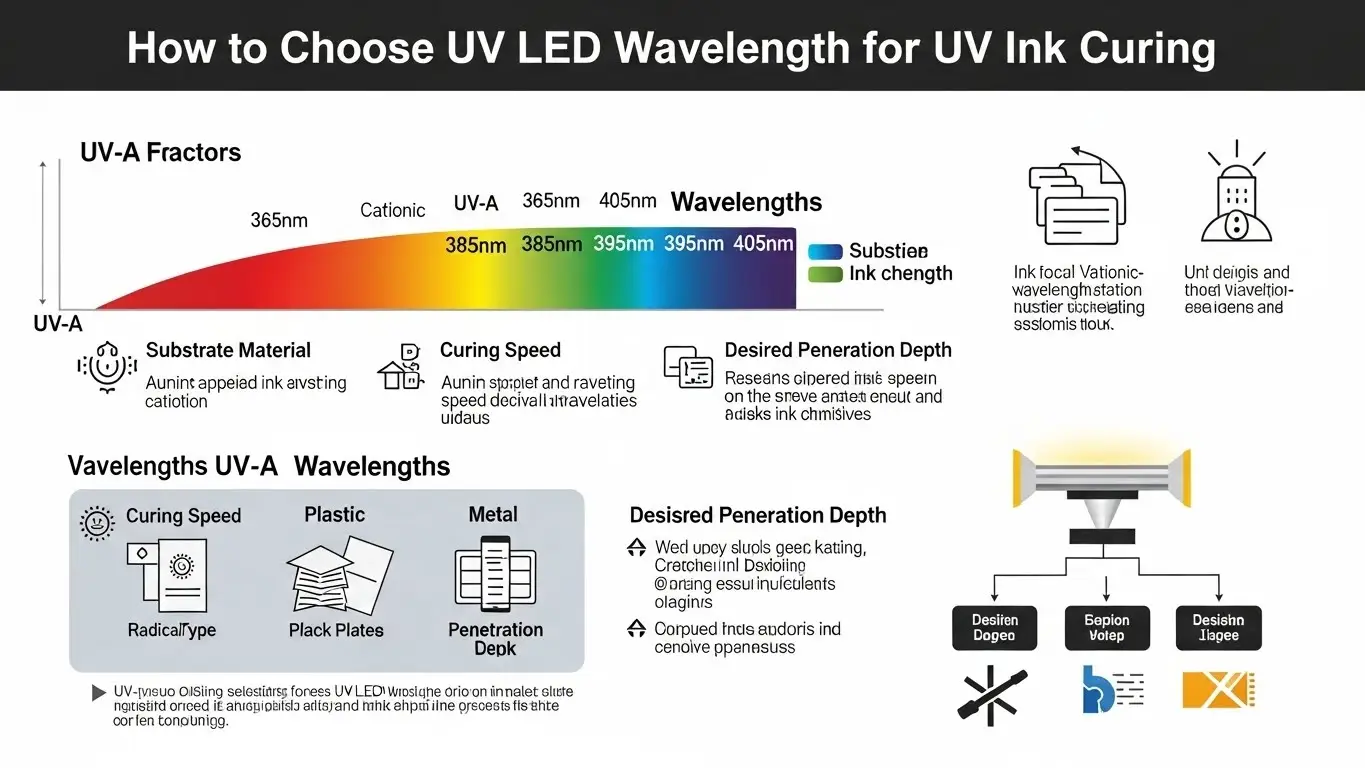

- Tailored for performance: Select the exact wavelength (365nm, 385nm, 395nm, 405nm) that best suits your materials.

- Compact and precise: Fit complex systems with small UV LED assemblies.

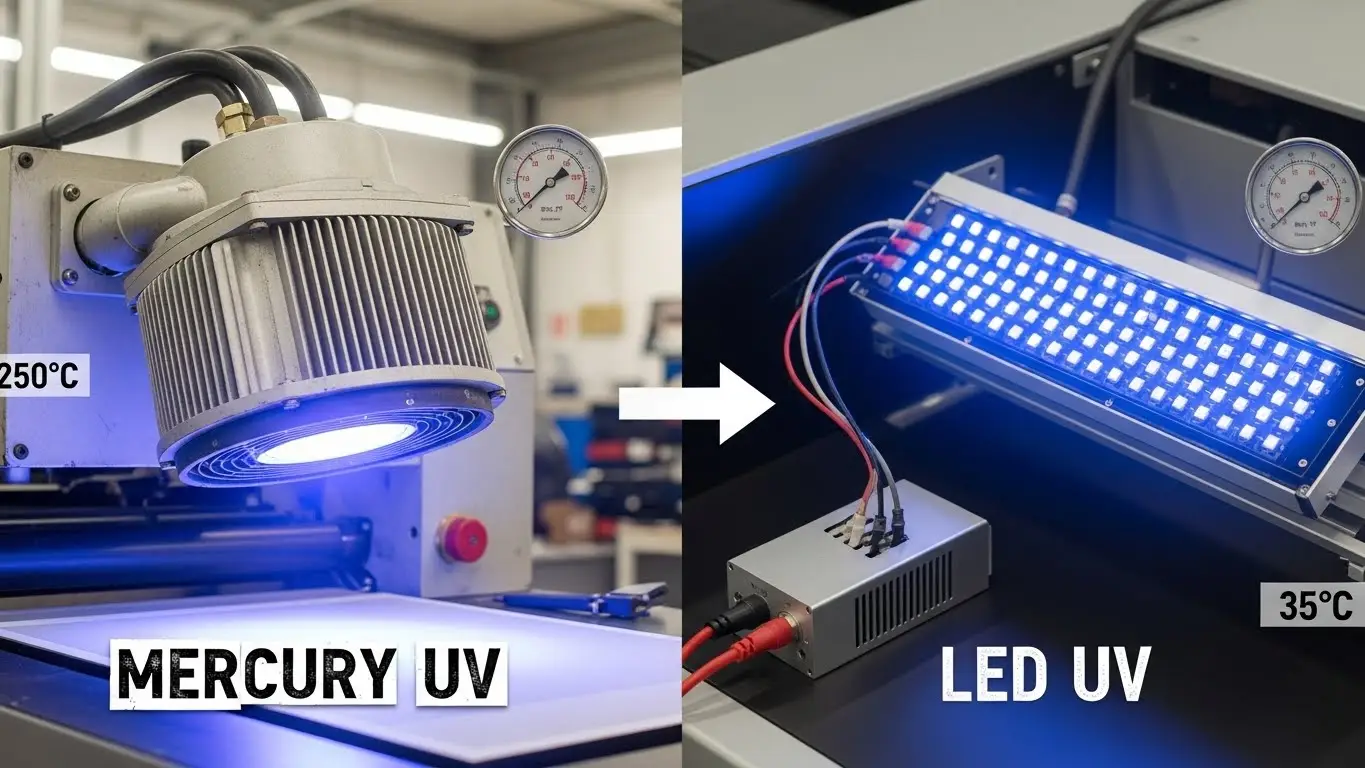

- Energy efficient: Reduced power consumption emits lower heat as well.

- Reliable: Active and passive thermal management systems maintain stressed environments.

- Fast integration: Designed with plug-and-play or low-friction system interoperability.

Medical and optical devices are designed with unrivaled efficacy in mind, and custom UV modules are provided as OEM.

Industries That Rely on OEM UV Solutions

Let's examine some of the UV OEM systems applications:

- Electronics Manufacturing

UV curing is an essential process in every step of the electronics’ life cycle, from PCBs to display panels. Our UV LED integration systems are broadly employed in:

- Adhesive bonding

- Conformal coating

- Fiber optic sealing

- Medical Device Assembly

Advantages of OEM UV Solutions include:

- Cleanroom-compatible curing

- Low-heat sterilization

- Reliable over time

- Printing & Packaging

UV systems are used in digital printing presses and label printers to improve print quality, reduce waste, and accelerate drying time.

- Optics & Optoelectronics

Custom optical systems and precision-bonded assembled optical lenses and sensors are made using tailored UV wavelengths and high-accuracy curing modules.

- Water & Air Treatment

Disinfection OEM UV systems are integrated into:

- Water filtration systems for residential use

- Office air purifiers

- HVAC duct systems

Critical Components for OEM UV Systems

The following components are necessary to guarantee the performance of ultraviolet light systems:

1. Arrays of UV LEDs

They are suitable for modular systems of UV curing and disinfection. They have:

- Low energy consumption.

- Long operational life.

- Constant output cancels stable wavelength output.

2. Cooling Mechanisms

Specific high-output areas require special thermal charges, rarity maintenance, and advanced outputs. Within this is a thermal regulation. Water-cooled fan buyers fan-cooled UV units.

3. Optical Lenses

With habits, they mold and position the UV beam to uniformly expose the items, including electronic laboratory work tools.

4. Controller A24 controllers

These provide enable multi-programmable devices with wavelength switching, some allow to set the device's tone through intensity control, and some permit to set the pulse on time pacing. Tailor-made engineering services offered by OEM UV engineers design all systems to suit custom specifications and specific applications.

OEM UV Curing Systems: Speed, Cleanliness, and Consistency

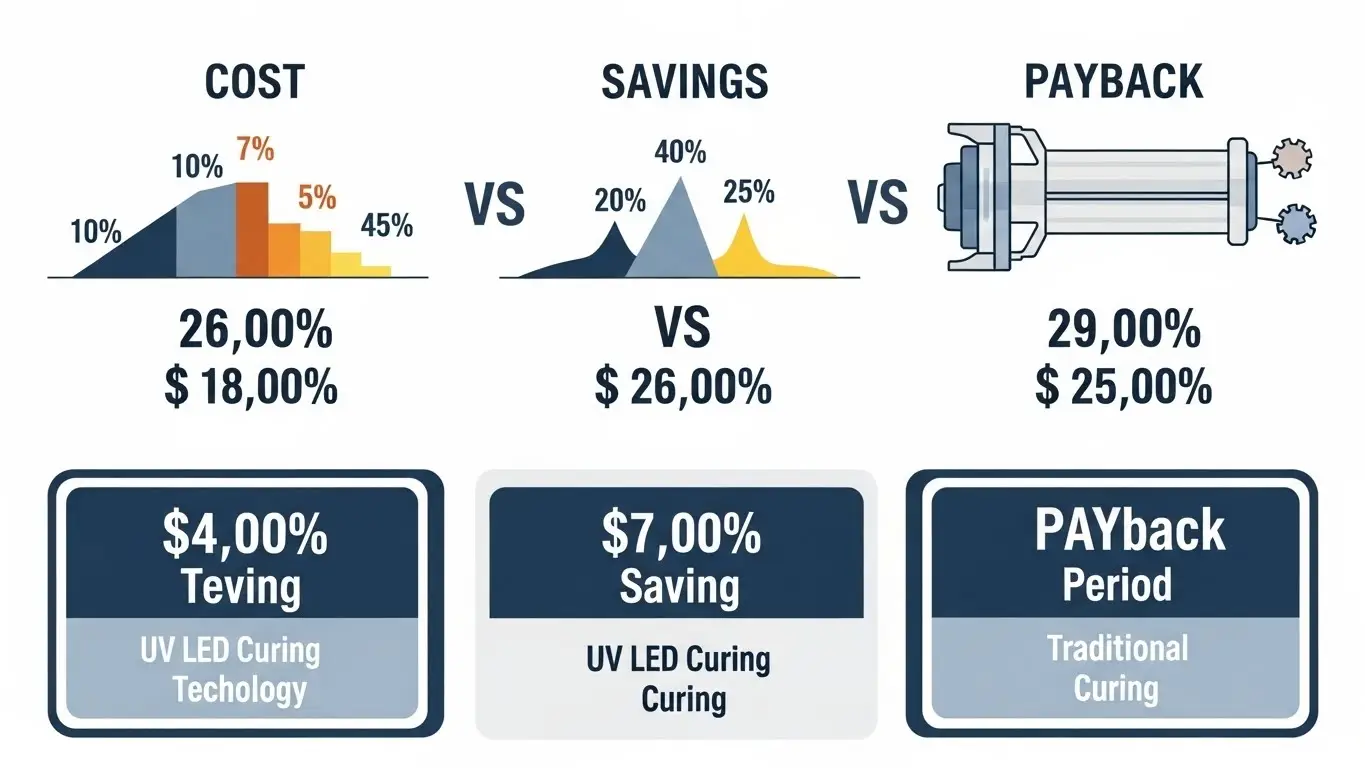

Curing stands as one of the most universally accepted uses of OEM UV solutions, and there is sound reasoning for that. The advantages of UV curing technology include:

- -Instant curing of adhesives and coatings

- -Lack of required curing time

- -Non-solvent, No VOC emissions

- -Uniform surface quality across all products

Our OEM UV curing systems have been designed for precision and reliability in industries such as 3D printing and semiconductor packaging. We will build a custom UV system to ensure complete integration.

OEM Solutions for UV Disinfection: Scalable and Safe

Disinfection has become a necessity in today’s world. From healthcare to HVAC or even residential spaces, comprehensive compact UV technology is required that is effective, reliable, and easy to incorporate into existing designs.

Our modules utilize UV-C wavelength technology (254nm) and are known to eliminate up to 99.9% of viruses, bacteria, mold, and heat-resistant microorganisms without the use of heat, ozone, or harsh chemicals. This makes our modules fast, safe, and eco-friendly. They are well-suited for:

• Hospital-grade equipment: HVAC secondary UV sterilizers, air handling units, portable and built-in air purification systems, and water dispensers and filtration devices. Trust our OEM clients to rely on the effectiveness and economy of our UV-C systems in critical operational environments.

Why Choose Our OEM UV Disinfection Modules?

- Efficient embedded application with compact design: Slim and space-saving form factor.

- Long Lifespan: UV emission sustained at 10,000 to 20,000 hours.

- Instant Operation: No warm-up period needed for UV activation.

- Low heat emission: Suitable for sensitive environments.

- Seamless Integration: Flexible proprietary designs adapt with existing product workflows.

- Sterilization methods without harmful chemicals or toxic byproducts: Greener than traditional methods.

Responding to specific design parameters for medical devices or smart air purifiers for homes, our OEM UV modules are fully customizable and programmable, thus easily scalable.

OEM UV Integration Services

At UVET, we go further than supplying UV lamps; we offer complete OEM UV Integration Services, which include:

- Design consultation to define the right solution

- Prototype development for your UV module testing

- Thermal and optical simulations for maximum performance

- Custom housing and lensing for safety and beam control

- Tailored firmware and equipment control systems.

Our customers receive unwavering support from us from the concept phase all the way through to production, providing certainty to the integration of the UV solution in OEM devices used in the field.

Conclusion

Choosing the right partner as an OEM UV supplier is critical as it determines system functionality and reliability. With decades of experience, quality engineering, and comprehensive project support offered by the team at UVET, there's no worry whether the demand is for a modular curing unit, a disinfection module, or fully embedded UV systems. We don’t just provide parts; our UV solutions are OEM-designed to operate seamlessly and endure diverse conditions and stresses.