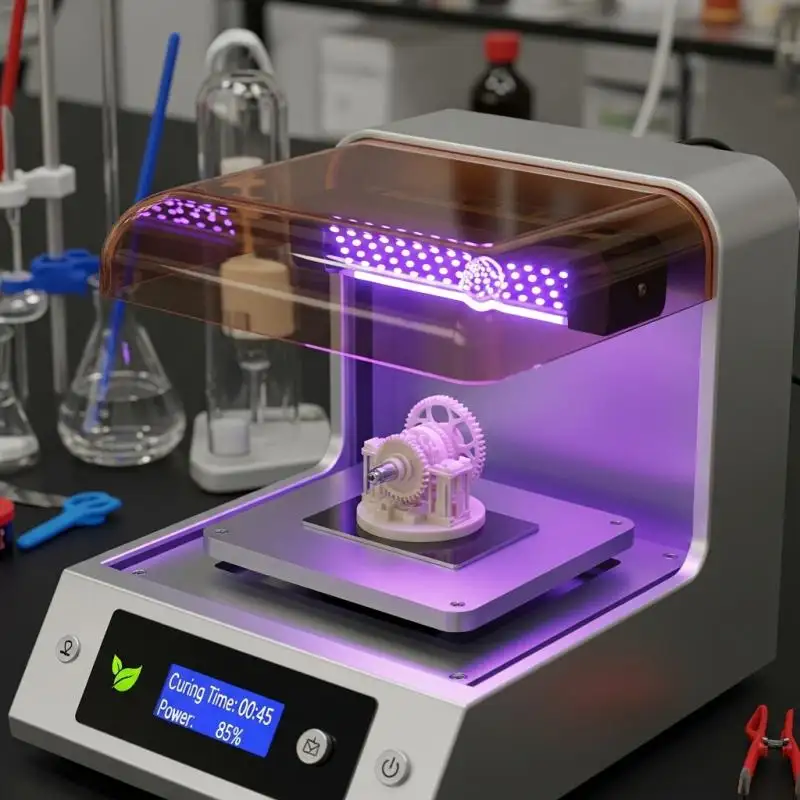

What is a Precision Curing System?

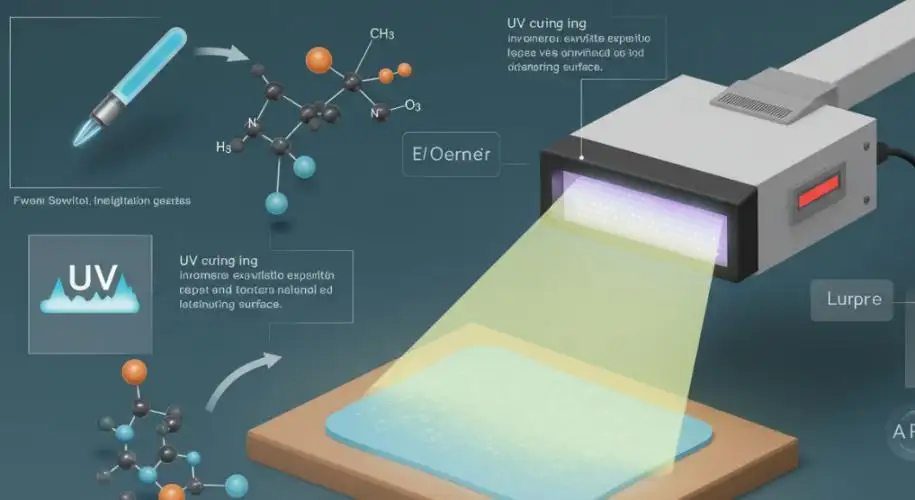

A precision curing system is a specialized tool that is used to provide controlled energy, such as UV light, thermal energy, or both, to cure adhesives, resin, polymer, or tapes with high precision and repeatability. In contrast to traditional curing systems, precise curing devices allow control of temperature, wavelength, and length of exposure to a line of micrometers, maximizing curing of delicate materials such as electronic assemblies, medical, and high-composite materials.

These systems have various configurations, such as the UV curing systems, in addition to the LED precision curing machines, the thermal curing systems, and hence they are applied in the fields that need speed and precision in curing in the industrial curing systems.

The main Characteristics of a Precision Curing System

The state-of-the-art precision curing system has a well-developed feature that increases productivity, consistency in the process, and energy efficiency:

Curing Technology of Control

Modern systems make use of digital curing control systems to control the curing cycle, which provides constant results. Light intensity, exposure time, and temperature parameters are carefully fine-tuned, and the process can be micro-precise enough to be applied in sensitive fields.

High-Intensity UV LED Lamps

These machines offer rapid delivery of energy with UV wavelength curing and the use of high-intensity curing lamps and reduced heat stress. This brings about the energy-saving curing systems, which are environmentally friendly and cost-effective.

Thermal Precision Curing

There are systems that are combined with thermal curing technology to offer dual-mode curing. This enables thermal and UV dual-mode accurate curing systems, which further increases their flexibility for many industrial applications.

Automated Curing Workflow

Production lines are provided with fast and reliable technology for curing, which is achieved through automation. Having automated precision control mechanisms allows operators to eliminate human error and have a constant curing output.

High Adaptability

Precision curing plants are made to be versatile. These systems can handle a variety of materials, wafer sizes, and tapes regardless of whether they deal with semiconductor wafers, glass, ceramics, or adhesives.

Applications

UV Tape Curing

UV tape curing is very important during the process of wafer dicing and back grinding. UV radiation decreases the adhesion of tapes, and it makes picking chips easier and enhancing the yield. UV dicing tapes can be treated to deposit on an extensive variety of materials such as semiconductors, glass, and ceramics; this makes it a very flexible industrial curing solution.

Industrial Manufacturing

Since electronic assembly curing technology has been applied to polymer and resin curing systems, precision curing has guaranteed high speed, dependable production with no loss of material integrity. Examples of medical equipment curing systems and the high-accuracy curing of adhesives provide an understanding of the scope of industrial use.

Adhesive and Resin Curing

The adhesive curing technology enjoys the advantage of surface hardening systems and accuracy in adhesive curing, so that they guarantee permanent bonding and uniform output. These systems combine UV LED curing technology and heat-controllable curing devices, and streamline the production cycles.

These specifications demonstrate the precision engineering systems due to which the curing operations are controlled by quality, the integration of production lines, and the quick and repeatable results.

Key Advantages

Productivity Improvement

The decrease in the tape adhesion and the use of the UV LED cold streaming allow the process of tape to be more productive. Shorter curing times and better suprachronic recovery save on the total hold times, resulting in better operational throughput.

Cost-Effective and Green

Modern systems also do not produce ozone emissions because they use mercury-free sources of LED lights, which means that they meet environmentalists' requirements. The industrial UV curing system saving energy system provides economical solutions with less environmental impact.

Easy Operation

Preset parameters can be easily manipulated by operators on touchscreen control interfaces to control various stages of the process to optimize workflow without much training.

Comprehensive Adaptability

The precise curing machines are capable of accepting different wafer sizes and tape configurations, meaning that they offer automated precision curing solutions to factories and provide uniform curing output regardless of the production line.

Incorporation with Advanced Manufacturing

The modern systems are created in such a way that they can be integrated into the factory automation systems. Smart curing technology can be used to automate UV-cure micro-components, and it offers manufacturers an industrial technology of the process that can support high-speed, high-volume production.

Microelectronics curing equipment and high-performance curing modules also permit wavelength-specific curing, heat-regulated curing, and controlled curing, which provides ultra-precise curing equipment to production lines.

What is the difference between UV LED Precision Curing Systems and other systems?

Rapid Curing Technology: Cure time can be as low as 5 seconds, based on material and tape type, and is perfect in high-speed curing equipment applications.

Dual-Mode: Systems may be fitted with a thermal and UV dual-mode precision curing system to be versatile.

Energy Efficiency: Low-temperature curing technology and LED cold light sources will save energy and increase the longevity of lamps.

Precision and Reliability: Precision curing processes and electronically controlled curing guarantee accuracy and lower error rates.

Improving the Quality of Production

Speed is not the only aspect that curing systems are about- quality, reliability, and repeatability. With the assistance of controlled curing technology, precision bonding and curing systems, as well as automated curing workflows, manufacturers can:

- Reduce the defects of the resin curing system and polymer curing system.

- Consistent bonding in adhesive bonding curing.

- Produce with optimization of the curing cycle.

- Increase the capacity to work with demanding materials such as ceramics, glass, and composites.

Conclusion

One tool that cannot be ignored in the contemporary world of manufacturing is a curing system, which is an interplay of sophisticated curing mechanisms, computerized control systems, and automation to bring about high accuracy, energy efficiency, and reliable curing.