What is Precision Spot Curing?

Precision spot curing is the controlled use of focused UV light to a particular spot, which can have a size as small as a few millimeters. This approach allows for:

- Localized adhesive cure, reducing the waste of materials.

- Sensitive parts require high-accuracy curing technology.

- Micro-spot UV curing to address the needs of small assemblies.

All these features make precision curing machines essential in those industries where the slightest error affects the quality of the products. LED spot curing technology allows manufacturers to obtain consistency in the UV curing cycles with consistent intensity and micro-spot curing reliability throughout the production cycle.

Technical Benefits of Precision Spot Curing

Current UV LED precise curing machines take advantage of new chip-on-board UV LEDs and narrow beam ultraviolet curing designs to provide focused energy to effectively cure. The technical benefits are:

- Spot curing LEDs with high output and the ability to produce intense UV energy at a low-heat operation.

- Photon emission control of fine irradiance spots.

- UV spot curing that entails thermal management to keep the system long-lasting and safe from materials.

- Control of UV wavelengths at nanometers, with adhesives, coatings, and resins customized.

All these technical advances have rendered precision spot curing an appropriate choice for applications spanning the mass production of industry, down to the micro-assembly of a part that must be produced with utmost accuracy.

Use of Precision Spot Curing in Industry

The list of industries for which precision spot curing systems can be used is quite extensive; it covers electronics, medical devices, automotive, and optical bonding.

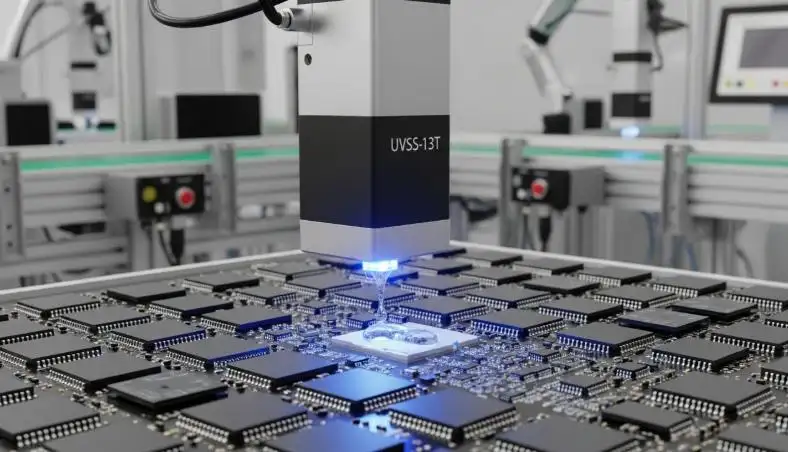

- PCB and Electronics Assembly

Electronic precision curing is important to provide a stable adhesion of electronic parts and finishes. PCB spot curing- UV spot cure is used to cure adhesives on complex circuit boards without exposing other components. Spotlight curing based on LEDs enables quick and repeatable outcomes, which are essential in high-speed production lines.

- Medical Device Assembly

Medical equipment requires curing systems of great precision when ensuring biocompatibility and integrity. UV spot curing of medical equipment is required to bond small and delicate components, and low-heat precision curing is required to preserve sensitive components and maintain high throughput.

- Automatic Bonding and Optical Bonding

Optical bonding spot curing involves the application of UV radiation to lenses, screens, or sensors to make a strong, transparent bonded adhesive. Targeted UV curing is also useful in the automotive industry, in which precision bonding is required in sensors, lights, and other interior parts.

- Adhesive and Coating Applications

Spot curing is available in terms of UV adhesive curing to UV resin spot curing, with polymerization occurring in a short time and being uniform. Localized polymerization can be accomplished by the manufacturers without exposing the surrounding areas for any reason, thus increasing efficiency and lessening post-processing requirements.

Applications of LED Technology in Precision Spot Curing

The LED spot curing technology has revolutionized the world of accurate UV curing. The contemporary UV LED spot curing systems are unique in several ways:

- The operation of instant-on does away with the warm-up times, enhancing productivity.

- Energy-efficient spot curing lowers operating expenses, and the output is high.

- Low-emission UV spot curing is in favor of green manufacturing.

- Modular design allows it to be used in automated lines or single configurations.

These characteristics enable industrial UV spot curing equipment to provide consistent output with extensive production cycles and provide a constant UV intensity level even in challenging environments.

Highlight on the UV LED Spot Curing System NSC4

The UV LED Spot Curing System NSC4 is one of the most developed systems to use in precision spot curing. This industrial adhesive system is developed to be used in adhesive applications; it is flexible, has high-intensity UV output, and is environmentally friendly.

Specifications:

- UV Wavelengths: 365nm, 385nm, 395nm, 405nm

- UV Spot Size: Ph3mm, Ph4mm, Ph5mm, Ph6mm, Ph8mm, Ph10mm, Ph12mm, Ph15mm.

- UV Power Adjustable Range: 10-100%

- Holes in the irradiation: 4 channels.

- Cooling: Natural / Fan cooling

Features and Benefits:

- High UV Intensity (Up to 14 W/cm2): Provides a high level of UV energy, which can be used to cure fast.

- Several Wavelength selections: Provides a wide range of UV-curable materials.

- Small, Square Form: Can be placed easily into automated lines or bench tops.

- Easy-to-use Interface: Slimmed controls make it easy to operate, and also, less training time is required.

- Consistent Curing: Will give consistent results with a minimum of heat effect.

- Sustainable and Mercury-Free: Eco-friendly operation will make sure the operation is in compliance and minimizes the carbon footprint.

NSC4 is best used in electronics, optics, and medical device assembly and has high throughput, high precision in coating and varnish curing, and can repeatable UV curing process which is used in demanding environments.

New Tendencies in Precision Spot Curing

Precision spot curing is an evolving field, and the innovations include:

- Precision spot curing systems based on next-generation technology with smaller and more focused beams.

- Intelligent UV micro-spot curing that can operate accordingly to the AI to optimize automation.

- Small spot curing systems to fit small high-precision assemblies.

- State-of-the-art LED spot curing technology that allows quicker curing time and greater efficiency.

These trends guarantee that precision spot curing will take a leading position in the industry and offer scalable, energy-saving, and corrective solutions to contemporary manufacturing.

Conclusion

Accurate spot curing is a revolutionary development in industrial production. It provides fast bonding with high intensity, high intensity and focused UV energy, which will allow it to cure adhesives, coatings, and optical bonding with excellent reliability and efficiency. With UV LED spot curing technology still evolving, the manufacturers enjoy access to energy-saving, low-heat, mercury-free, and AI-finished solutions that move productivity and enable operations that are eco-friendly. Precision spot curing machines will provide high-quality, repeatable results today, shortened cycle times, and a green future for the UV curing technology. Visit UVET.