High-performance Industrial and Technical Lighting

In this modernized industrial/technological world, precise and dependable UV light is essential in the fields of electronics to assemble medical equipment and other devices. Precision UV illumination has become one of the solutions, offering controlled, high-intensity UV light that is able to provide high levels of precision, uniformity, and repeatable outcomes.

In industrial UV illumination solutions, UV LED precision light systems and controlled UV lighting systems, these technologies allow unrivaled performance to the contemporary manufacturing, inspection, and quality control processes.

Learning about Precision UV Illumination

It is defined as specific harmful delivery of the ultraviolet light with the help of the high-performance LED or conventional UV light to create uniform curing, examination or photopolymerization outcomes. The LED UV illumination systems, in contrast to traditional UV lamps, can be regulated and offer a high level of precision with little thermal disturbance, unlike traditional UV lamps, which may be difficult to predict and may emit too much heat.

The main benefits of accurate ultraviolet lighting are:

- Even light distribution during quick and precise curing.

- Minimum heat production of delicate materials.

- Green efficiency and use of long-lasting LEDs.

- On-off without a warm-up period.

- Interoperability with various industrial applications.

A perfect application of photopolymerization with accuracy UV involves the use of UV photons to convert a liquid into a solid substance by initiating a chemical reaction in the photosensitive material, i.e. an adhesive, coating or ink. This is a reaction that needs to be highly regulated, and the use of accurate UV LED light reaction guarantees that the reaction is reproducible among production lines.

UV LED Curing Device is prefect for UV illumination

UV LED Curing Device is a high efficiency ring type system that is compact. It has a steady and managed UV light to provide over precision in the curing process. Having an irradiation size of Ph25mm to Ph50mm, a choice of wavelength of 365nm, 385nm, 395nm or 405nm, it supports a wide scope of UV-sensitive material.

This healing apparatus finds extensive application in electronics, optics as well as medical device assembly. It guarantees high cleaning speed and results that are fast to cure and have a high degree of reliability. Water-cooled design assists in keeping the operating temperatures down even in case of long running.

Features

Irradiation zone (Ph25-Ph50mm): Accurate curing of UV light with focused energy.

Various wavelength (365nm, 385nm, 395nm, 405nm): Adaptable to various materials.

Water-cooled thermal regulation: Constant operation and cooling.

Turn-on/turn-off control: No warming up period and less consumption of energy.

Easy to use with minimal training: user friendliness.

Low heat production: Covers the fragile components and materials.

Industrial Applications Benefits

- The UV LED Curing Device is applicable to many narrow jobs. It is used in electronics to bond, seal and to assemble at a micro scale. Such applications have the advantage of high curing and minimized heat effect.

- Medically, the system is used to bond the parts such as catheters and diagnostic housings. It is clean and safe in working with delicate parts. In optoelectronics, it aids in aligning and fixing the lenses, filters and sensors. The equipment guarantees complete coverage of UV without destroying the materials.

- Its beam has stability to enable even the surface that is complex or detailed to cure evenly. This consistency renders it suitable in repetitive production.

What is Special about this UV LED Curing Device?

This LED-driven device is also a no warm-up, immediate operation compared to the traditional curing systems. It does not generate a lot of heat and this is safe with delicate materials. It has four wavelength options making it easy to fit to other adhesives and coatings.

Integration is simple. It can be placed in benchtop stations or in automated lines with very little configuration. It can be used either in spot curing or in more detailed bonding, and it is precise, fast and efficient.

Maintenance and saving of energy are also supported in the UV LED Curing Device. Its extended lifespan of LED and clean operation minimizes down time and operation costs.

Characteristic Technologies of Precision UV Lighting Systems

Intensive and Focused Delivery

The output of UV LED illumination modules is high and the energy can be focused in areas where it is likely to be required. Through the technology of UV LED precision lighting, the industries are able to obtain faster curing time, enhanced adhesive bonding, and homogeneous coating outcomes.

Adjustable and Removable Design

Unlike in the past, modern precision UV LED illumination systems commonly have a modular UV illumination system, which enables the operator to design arrays depending on the size of the application, geometry, and required coverage. Modularity improves flexibility whether in a portable precision UV illumination solution or in large-scale industrial systems.

Low Heat and Energy Efficiency

These systems that consume less energy reduce the amount of electricity consumed but provide high-intensity UV illumination. Low heat production conserves heat sensitive units, including electronic assemblies, medical equipment and sensitive coatings.

Flexibility in the Industries

Industrial Precision UV lighting has many industries in its range:

Electronics: Bonding, encapsulation, and coating Electronics Precision UV LED electroluminescence permits dependable bonding, encapsulation, and coating of components without component destruction.

Stereo Medical Equipment: Precision UV illumination on medical devices is useful in medical equipment, sterile bonding, and assembly.

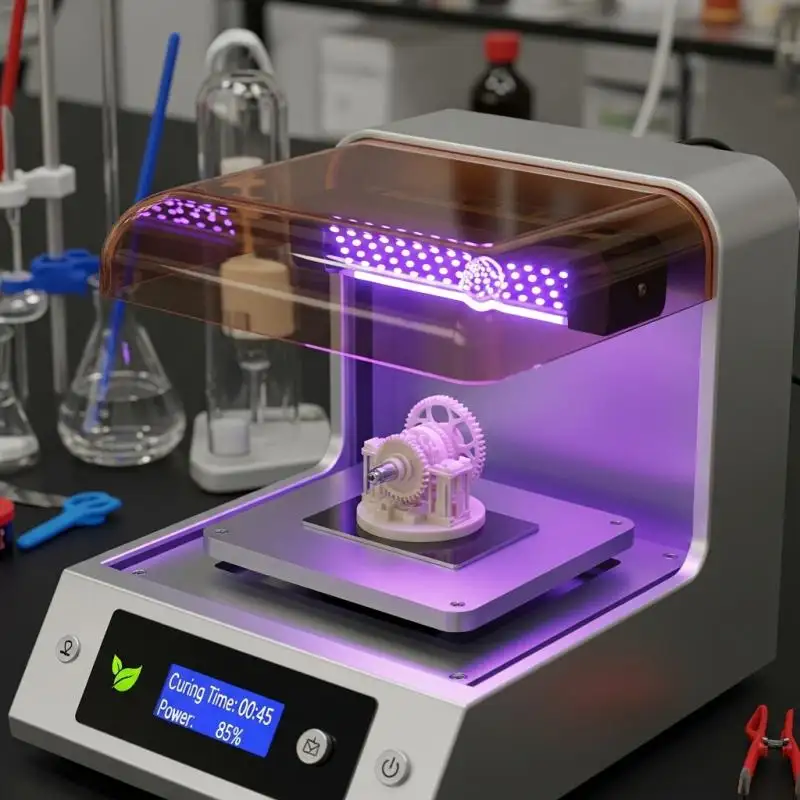

3D Printing: UV light UV lights used in 3D printing will provide a high-resolution printing of parts.

Automotive: Industrial UV light solutions are effective in delivering long-lasting outcomes in adhesives and coatings.

Laboratories & Optics: High-accuracy inspection and calibration High-accuracy UV LED illumination in laboratories and precision illumination in optics.

The future of Precision UV Illumination

With the growing need in industries to continually enhance efficiency, accuracy, and flexibility, precision UV illumination systems are developing with:

- Portable accuracy UV lighting systems in mobile processes.

- Faster curing with high intensity precision illumination systems.

- Speciality UV LED lighting systems Custom precision lights.

Scalable and repeatable processes can be integrated with automated production lines.

The development in the UV LED-specific lighting technology enables the industries to obtain a stable UV output to enable accurate curing, low-heat processing, and low-energy consumption UV lighting to meet their current sustainability and productivity requirements.

Conclusion

Industrial processes are becoming enhanced with precision UV illumination, which delivers high-intensity, targeted, and reliable ultraviolet light to multiple applications. These systems produce high quality, fast, and uniform results in electronics assembly as well as in medical device production and 3D printing.

To learn more about high-performance precision illumination applications and equipment, go to UVET.