UV Printing - A Detailed Guide

What is UV Printing?

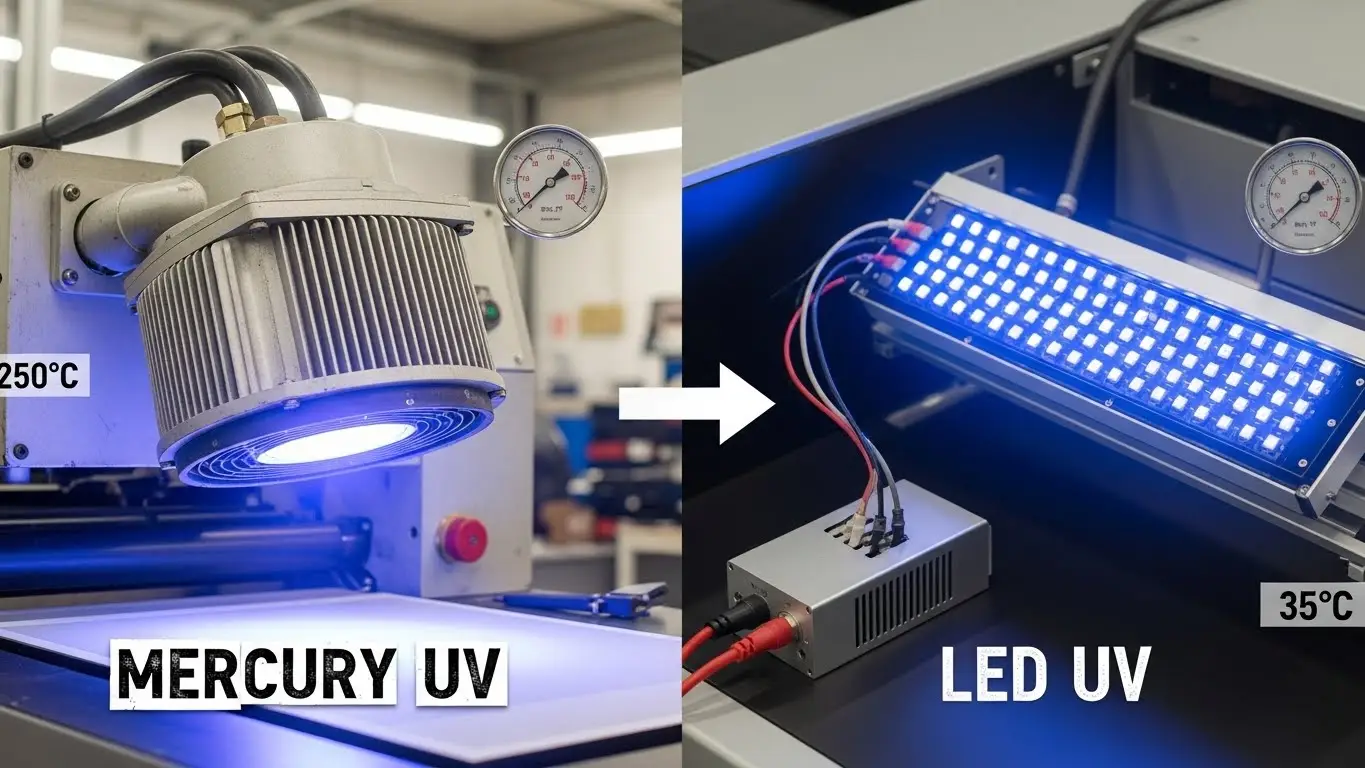

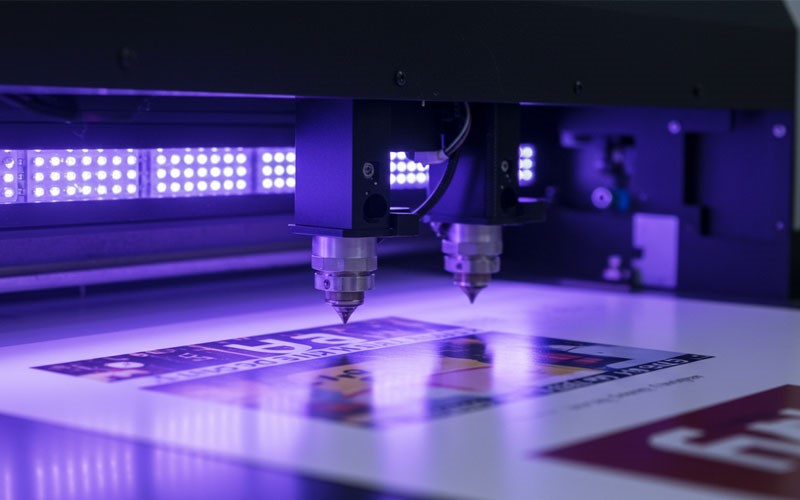

UV (Ultraviolet) printing is one of the most developed digital and UV printing technologies, in particular, saving time and energy by 60% by curing or drying inks, coatings, or varnishes employing UV light throughout the printing process. Unlike past methods, which use heating or hot air-assisted drying, UV printing utilizes UV inks that are kept in liquid form until contact with the UV LED light is made, at which point they are instantly cured or hardened.

The technology is eco-friendly while also yielding faster production rates, higher quality prints, and improved durability. It is extensively adopted across a plethora of sectors such as packaging, signage, electronics, labels, and promotional materials. Ideal for offset, flexo, and inkjet printing.

Features of UV Printing

- UV LED Curing: This feature uses UV lights to instantaneously cure specially formulated inks on contact with the substrate.

- Direct-to-substrate Printing: Printing is done on the surface of different materials without the use of intermediate layers.

- Vibrant Color Range: The technology can obtain different colors of paints, and it is guaranteed that they will not fade due to the instant drying feature.

- High Resolution Accurate Prints: With this technology, intricate designs and detailed prints with sharp text are made effortless.

- Multi-layered Printing Ability: It is capable of producing multi-layered prints with special features such as white under printing or spot varnishing.

- Energy Efficiency: When compared to traditional UV lamps, LED UV equipment uses considerably less power.

- Long Lamp Lifespan: The operational life of UV LED lamps is longer, which lowers downtimes and costs associated with replacements.

Applications of UV Printing

The distinct features and flexibility of UV printing technology make it useful in a variety of fields, including:

• Signage and Displays: Preparing outdoor and indoor signs, banners, posters, exhibition graphics, and point-of-sale displays that are scratch-resistant and long-lasting.

• Packaging: Directly printing onto the packaging materials like cardboard, plastics, and glass for product boxes, bottles, and containers.

UV LED for Printing

• Promotional Products: Logo and design application on a diverse array of products such as pens, phone cases, lighters, USB drives, key chains, and even golf balls.

• Industrial Printing: Marking and decorating industrial components such as control panels, electronic devices, and automotive parts.

• Self-Created Personalized Items: Designing custom gifts such as phone cases, stationery, photo albums, and other decorative items where the customers’ choice of design is used.

• Medical and Pharmaceutical: Marking devices and equipment together with their packaging with high precision and durability for medical and pharmaceutical use.

What We Offer: Tailored OEM/ ODM Services of UV LED Technologies?

Custom UV LED solutions that UVET is capable of providing include the power that exists within the precision development of offered technology, as well as grant support for optimum integration into workflows are developed at the work of ODM or OEM subsidiaries.

Why UVET?

Equally important for the work of UVET with the value relation towards production and processes is equally advocated synergy incidence amid the great Sea, where great quality proactive amenities and importance striving to sustain benefits towards gaining more customers found at the center of Flexible Advanced Analytics.”

· Industry Relationships:

Due to our expertise in pioneering UV LED research and development, coupled with advanced manufacturing and industry relations, UVET has over a decade of understanding the industry's UV needs. Through years of relentless innovation, we have advanced our technologies, exceeding the demands of our clientele by ensuring efficiency and superior quality.

·Strategic Customization:

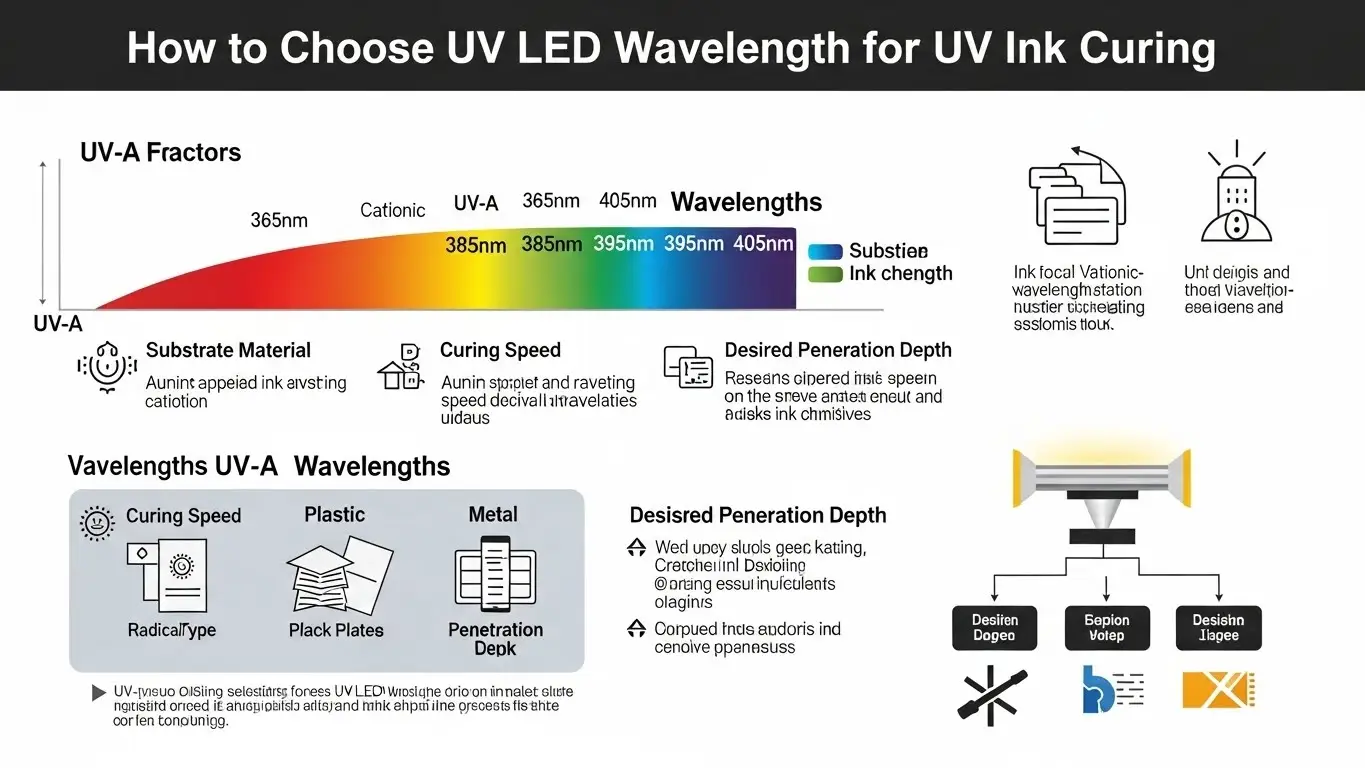

Extending beyond tailoring UV capabilities, UVET provides unparalleled customization options. As we are tailored to each specific case, our clients have incredible precision in specifying critical parameters, including the ability to specify laser-calibrated wavelengths for increased effectiveness in their unique applications. Special optimizations guarantee maximum efficiency and effectiveness.

· High Quality Assurance Standards:

UVET employs industry best practices for guidelines concerning environments and ensures safety and health practices are effective and compliant with industry and internal benchmarks. All products and services are subject to UVET's internal policies, procedures, and documents. Meeting international standards and possessing CE, RoHS, and ISO certifications are the benchmarks and standards of operational constructs throughout the company. Vigilantly maintaining an unyielding commitment to unrivaled quality and safety ensures utmost environmental efficacy and stringent management of product capabilities.

· Strong Technical Support:

UVET goes beyond the sale, offering integrated support for the entire lifecycle of your UV LED solution. Our seasoned experts assist from the design and development phase, collaborating closely with you for seamless integration and optimal system performance.

· Flexible Production Capacity:

UVET's flexible production capacity allows for the immediate production of small batches of prototypes for thorough initial testing and refinement, as well as scaling up to large-scale production to meet substantial volume demands. Our advanced manufacturing infrastructure is equipped to handle both small and large orders with exceptional efficiency and effectiveness, maintaining an unwavering commitment to the highest quality standards.

Advantages of UV Printing

• Unmatched Speed and Efficiency: Drying inks and coatings instantly accelerates production speeds by 300%, substantially improving turnaround times and increasing throughput.

• Superior Print Quality: Print quality is unprecedented when it comes to vibrant colors and images, as ink smudging and blurring are prevented through instant drying on the substrate surface. Super Sharp is well known for providing exceptional clarity.

• Versatility in Substrates: There is greater flexibility in printing applications due to Super Sharp's UV ink jet printer, Round Print 522's compatibility with various materials such as paper, plastics, metals, glass, wood, and acrylic.

• Cost-Effective for Short Runs: Super Sharp printers have economical options when it comes to small batch customization projects due to reduced setup costs and waste associated with traditional printing.

• Space-Saving Design: Super Sharp models are easier to incorporate into existing printing setups due to their compact size, which increases flexibility in workflows.

Transform Your Printing Procedures with UVET

We at UVET do more than furnish you with services and resources; we commit to aiding you on an unparalleled journey towards achieving printing perfection. From your specific requirements, we guarantee innovation, customized solutions, quality, coverage, and support, receiving nothing less than bespoke solutions in UV printing and LED technology. With UVET, you are certain to achieve unparalleled efficiency, unmatched quality, and optimal sustainability - experience the magnetism of the UVET advantage.

Contact us today to elaborate on your business needs, and let us demonstrate how UVET's unmatched ingenuity can propel your business to new milestones of success. In this era of fierce marketplace competition, we guarantee relentless devotion towards securing for you the cutting-edge technology and expert guidance; let us aid you together in endless possibilities. Let us partner together towards reengineering your processes and collaboratively accomplish defined expectations with enduring impact.

- PREV: UV LED for Medical Devices: The Ultimate Guide 2025

- NEXT: Null