Handheld UV LED Curing Lamp 150x80mm Series

- Model: HLS-48F5

- 365nm

- 385nm

- 395nm

- 405nm

UVET has developed a high intensity handheld UV LED curing lamp. This portable lamp distributes even UV light over an area of 150x80mm and is available in four wavelength options: 365nm, 385nm, 395nm and 405nm. With a powerful intensity of 300mW/cm2 at 365nm, it can achieve efficient and rapid curing in just seconds.

Specifications

| Part No. HLS-48F5 | Wavelength 365nm, Intensity 300mW/cm2 |

| Part No. HLE-48F5 | Wavelength 385nm, Intensity 350W/cm2 |

| Part No. HLN-48F5 | Wavelength 395nm, Intensity 350mW/cm2 |

| Part No. HLZ-48F5 | Wavelength 405nm, Intensity 350mW/cm2 |

| Irradiation Area | 150x80mm |

| Heat Dissipation | Fan cooling |

-

Descriptions

This lamp features an ergonomic, compact and lightweight design to ensure user comfort during prolonged use. Utilizing advanced LED technology, it can provide instant on/off functionality without emitting infrared light or ozone, making it ideal for wood, veneer and other heat sensitive materials.

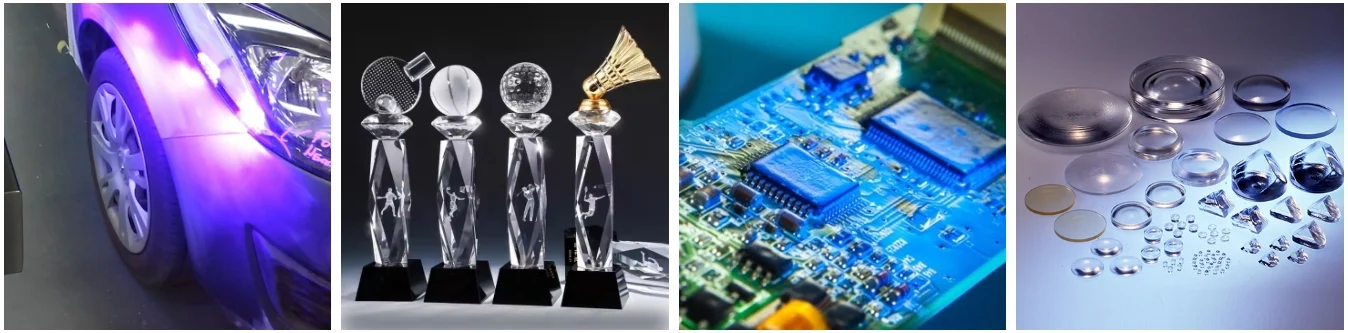

In the automotive industry, the LED UV curing lamp is widely used to cure UV coatings and protective layers on vehicle surfaces. The curing process involves exposing the applied coating to ultraviolet light, which triggers a chemical reaction.Traditional drying methods can take hours, but with LED UV curing the process can be reduced to minutes. This rapid cure not only speeds up production times and significantly increases productivity, but also ensures a high-quality surface finish that is resistant to scratches, chemicals and environmental factors.

In addition to their efficiency, LED UV curing lamps are also very environmentally friendly. They consume less energy than traditional curing methods, helping to reduce the overall carbon footprint of vehicle production. This shift towards sustainable manufacturing practices is in line with the industry's growing emphasis on environmentally friendly technologies, and as the automotive industry continues to evolve, demand for innovative solutions such as LED UV curing lamps is expected to rise.

UVET's portable UV LED curing lamp offers numerous advantages, making them ideal for fast curing of filled and painted areas. Its powerful output ensures an effective and efficient curing process. A variety of wavelength options are available to meet different curing requirements. In addition, its environmentally friendly UV LED modules effectively replace traditional mercury bulbs and can cure heat-sensitive materials while minimizing power consumption and environmental impact.

-

FAQs

1. What materials can the portable UV LED curing lamp be used for?

A: This lamp is ideal for curing wood, veneer, adhesives, coatings, and other heat-sensitive materials. Its LED technology ensures minimal heat emission, making it safe for delicate surfaces.

2. What are the available wavelength options?

A: The lamp is available in 365nm, 385nm, 395nm, and 405nm, allowing compatibility with different curing applications and materials.

3. What is the UV intensity and curing efficiency?

A: At 365nm, the lamp delivers an intensity of 300mW/cm², enabling fast and efficient curing within seconds. The even light distribution over 150x80mm ensures consistent results.

4. Is the lamp easy to use for long durations?

A: Yes! The lamp is designed to be lightweight, compact, and ergonomic, reducing hand fatigue during extended use. It also features instant on/off functionality without generating infrared heat or ozone, ensuring user comfort.