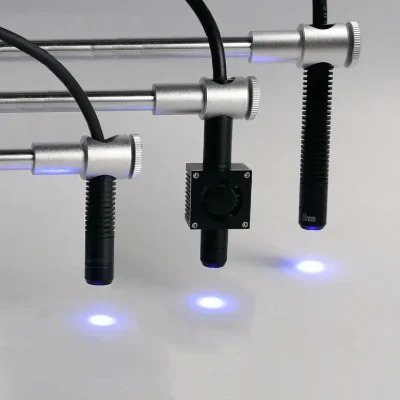

UV LED Spot Curing System NSC4

- Model: NSC4

- 365nm

- 385nm

- 395nm

- 405nm

- UV Wavelength: 365nm,385nm, 395nm, 405nm

- UV Spot Size: Φ3mm, Φ4mm, Φ5mm, Φ6mm

Specifications

| Model No. | NSC4 |

| UV Power Adjustable Range | 10~100% |

| Irradiation Channel | 4 channels; Independent running each channel |

| UV Spot Size | Φ3mm, Φ4mm, Φ5mm, Φ6mm,Φ8mm, Φ10mm,Φ12mm,Φ15mm |

| UV Wavelength | 365nm,385nm, 395nm, 405nm |

| UV LED Cooling | Natural / Fan cooling |

-

Descriptions

The NSC4 UV LED curing system is an efficient and high-intensity curing solution, delivering up to 14W/cm² of UV output. With optional wavelengths of 365nm, 385nm, 395nm, and 405nm, this system provides flexibility and compatibility with a wide range of curable materials, ensuring precise and reliable curing for diverse industrial applications.

Seamless Integration & Versatile Applications

✅ Compact & Modular Design – Easily integrates into production lines and benchtop workstations, enabling a smooth transition into existing workflows.

✅ User-Friendly Interface – Simplifies setup and operation, minimizing training time.

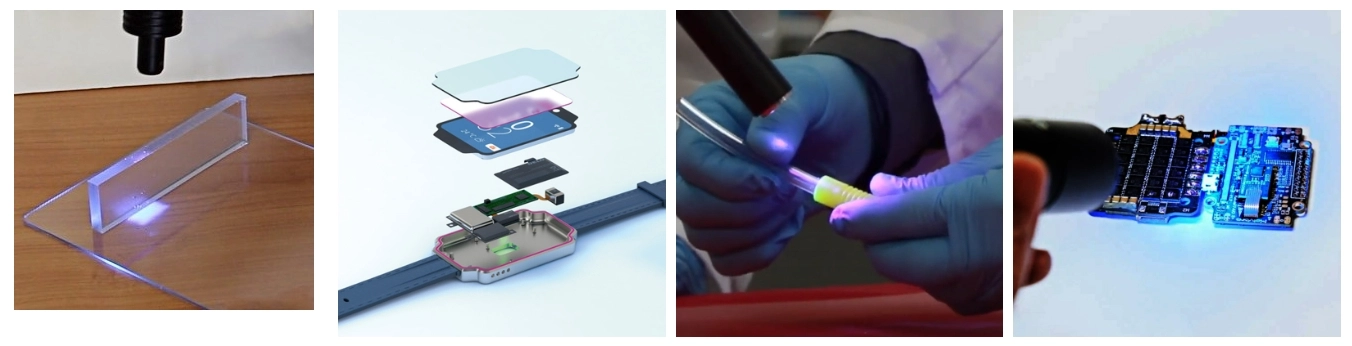

✅ Multi-Industry Compatibility – Suitable for bonding, fixing, and encapsulating in electronics, optics, and medical manufacturing.Why Choose NSC4?

- High UV Intensity, Up to 14W/cm² ensures fast, uniform curing.

- Multiple Wavelengths, 365nm, 385nm, 395nm, 405nm for material compatibility.

- Seamless Production Integration, Works with existing automation setups.

- Superior Quality & Reliability, Ensures consistent curing performance for industrial applications.

-

Applications

The NSC4 UV LED curing system is an efficient curing solution that delivers high UV intensity of up to 14W/cm2. With optional wavelengths of 365nm, 385nm, 395nm and 405nm, this system offers flexibility and compatibility with a variety of materials used in the curing process. This versatility enables precise and efficient curing, ensuring that different types of materials can be cured with maximum efficiency.

One of the key features of the NSC4 is its seamless integration into production lines. Its compact design and user-friendly interface make it easy to install and operate, allowing for a smooth transition into existing manufacturing processes. What’s more, this versatile curing system is suitable for a variety of applications in different industries. It can provide reliable results for bonding, fixing or encapsulating of components in the electronic, optical or medical-technical sector.

In addition, the NSC4 is equipped with a variety of focusing lenses, allowing the system to deliver high UV intensity precisely where it is needed. This level of precision ensures that the curing process is optimized for each specific application, resulting in exceptional quality and consistency.

In summary, the NSC4 UV LED curing lamp represents a major advance in curing technology. Its high UV intensity, multiple wavelength options, seamless integration and wide range of applications make it a valuable asset for manufacturers looking to optimize their curing process.

-

FAQs

1. What materials can the NSC4 UV LED curing system be used for?

A: The NSC4 is compatible with a wide range of materials, including adhesives, coatings, inks, and resins. It works effectively with materials that require high UV intensity for curing, particularly in industries such as medical, electronics, automotive, and optical.

2. Can the NSC4 system be customized for specific production line requirements?

A: Yes, the NSC4 system is highly customizable. We offer various focusing lenses and optional wavelengths (365nm, 385nm, 395nm, and 405nm) to meet the unique needs of different materials and production environments.

3. What is the maximum curing intensity of the NSC4 system?

A: The NSC4 offers a high UV intensity of up to 14W/cm², ensuring fast and efficient curing for a wide variety of applications, providing optimal results even for challenging curing processes.

4. How easy is it to integrate the NSC4 system into an existing production line?

A: The NSC4 is designed with a compact structure, making it easy to integrate into existing production lines. It is compatible with various setups, providing flexibility for seamless integration and precise, efficient curing without disrupting your workflow.