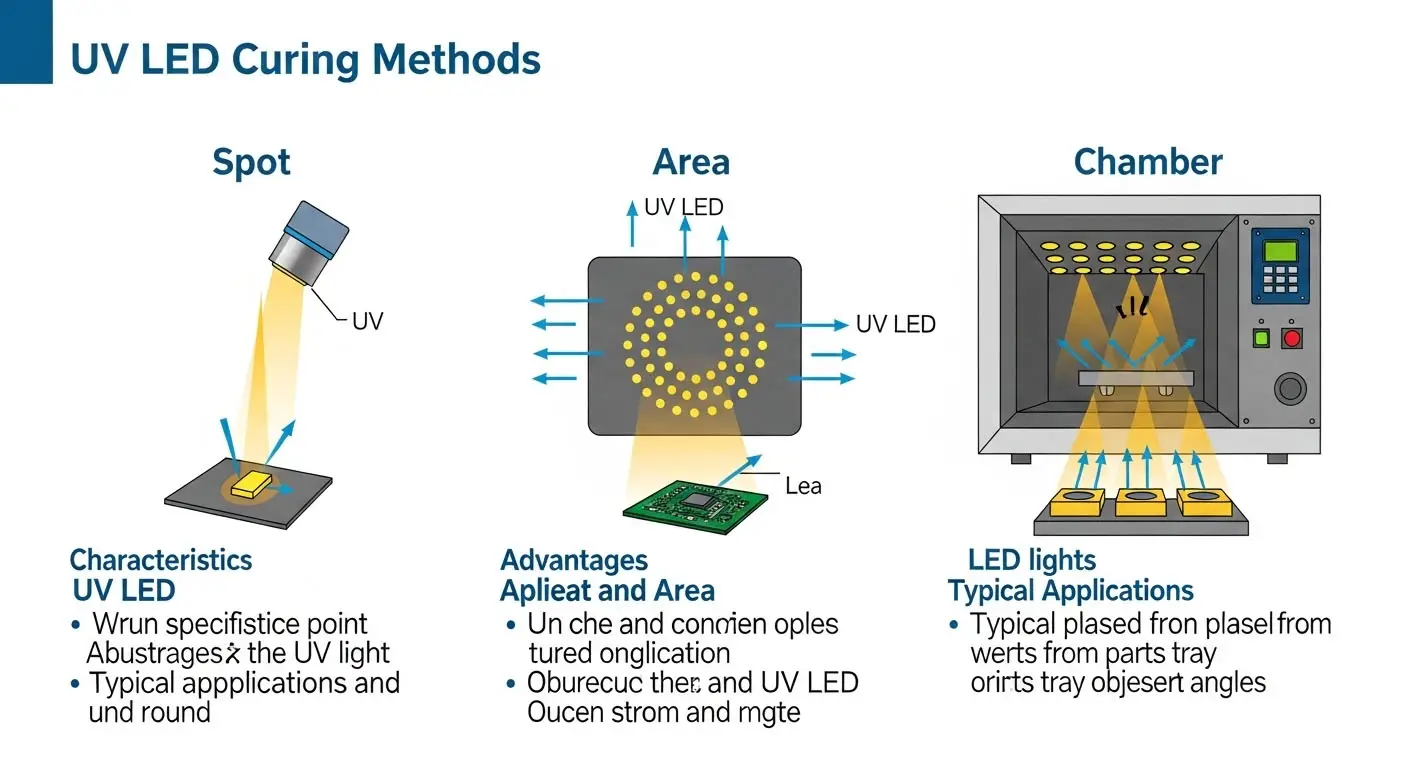

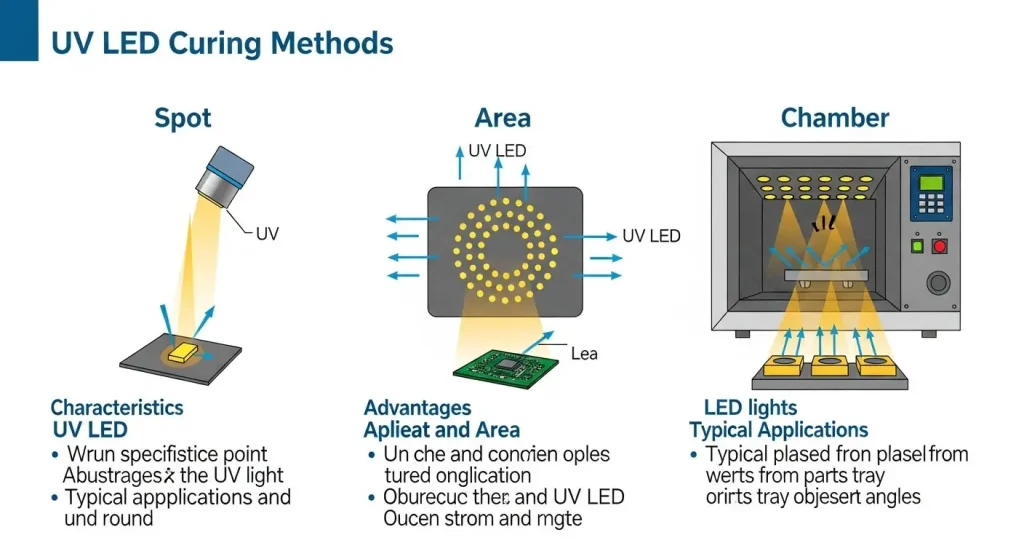

Spot vs. Area vs. Chamber UV LED Curing: Optimal Applications

The image shows three distinct UV LED curing approaches, each designed for specific applications. Let me break down when each method makes the most sense:

Spot UV LED Curing

Ideal for precision applications requiring targeted curing:

- Electronics Manufacturing: Component bonding, wire tacking, and precise adhesive curing on PCBs

- Medical Device Assembly: Catheter bonding, needle assembly, and guidewire coating where precision is critical

- Optical Component Production: Lens bonding and fiber optic connections

- Selective Finishing: Targeted texturing, logo highlighting, and embellishments on packaging

Key advantages: Precise control, minimal heat transfer to surrounding areas, energy efficiency (70-80% less electricity than conventional systems), and instant on/off capability for rapid processing.

Area (Flood) UV LED Curing

Best for uniform curing across flat or relatively flat surfaces:

- PCB Manufacturing: Uniform curing of conformal coatings across entire circuit boards

- Printing Industry: Full-surface curing of inks, coatings, and finishes on labels and packaging

- Display Manufacturing: Bonding and sealing components in flat panel displays

- Batch Processing: Curing multiple small components simultaneously on a production line

Key advantages: Even illumination across larger surfaces (typically 4"×4" to 12"×12"), higher throughput for flat items, consistent results, and easy integration into conveyor systems for continuous processing.

Chamber UV LED Curing

Optimal for complex three-dimensional products:

- Medical Device Manufacturing: Complete assembly of catheters, balloons, Y-connectors, and tubing sets

- Electronics Encapsulation: Full sealing of electronic components with complex geometries

- 3D Product Assembly: Products with multiple bonding points that require curing from all angles

- Laboratory Testing: Controlled environment for R&D applications and prototyping

- Small Batch Production: Multiple items cured simultaneously in a controlled environment

Key advantages: 360° exposure eliminating shadowing issues, controlled environment for consistent results, batch processing capability with multiple shelves, and no need to rotate parts during curing.

Selection Criteria

When choosing between these methods, consider:

- Part Geometry:

- Simple flat surfaces → Area curing

- Precise small locations → Spot curing

- Complex 3D shapes → Chamber curing

- Production Volume:

- Low volume with high precision → Spot curing

- Medium to high volume flat items → Area curing

- Small to medium batches of complex items → Chamber curing

- Heat Sensitivity:

- Highly heat-sensitive components → Spot curing (lowest heat transfer)

- Temperature-sensitive materials → Any method with appropriate intensity control

- Multiple cure points on a single item → Chamber curing

- Investment Considerations:

- Lower initial cost → Spot curing

- Moderate initial cost for larger surfaces → Area curing

- Higher initial cost but reduced labor → Chamber curing

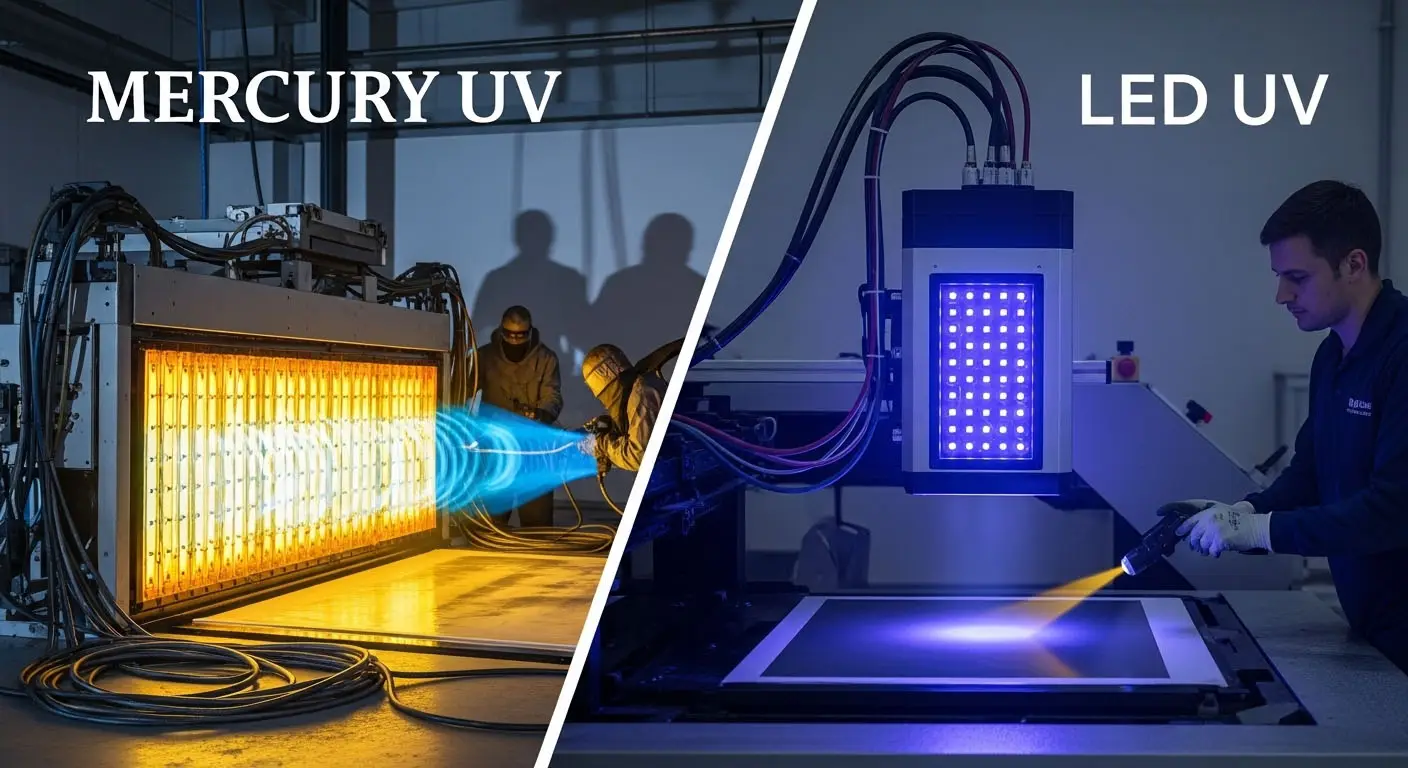

All three methods offer significant environmental benefits over traditional mercury-based systems, including mercury-free operation, reduced ozone production, lower VOC emissions, and extended operational lifespans exceeding 10,000 hours compared to 1,000-2,000 hours for conventional UV lamps.