Surface Crack Detection UV: Ensure Flawless Quality

Introduction to Ultraviolet Surface Crack Detection

Modern non-destructive testing (NDT) heavily relies on ultraviolet (UV) light for surface crack detection. This technique is commonly known as Fluorescent Penetrant Inspection (FPI). It plays a vital role in high-integrity industries. Consequently, with the aid of surface crack detection UV, inspectors can easily find the smallest defects on the surfaces that can affect the safety and performance of materials.

What is Surface Crack Detection?

Surface crack detection UV refers to identifying irregularities occurring on the material’s surface, which may result in failures if undiscovered. These cracks might be due to manufacturing faults, fatigue, corrosion, or other stressors. The conventional methods may not detect these complex flaws; however, by applying UV-based techniques, their sensitivity can be enhanced.

The Role of UV Light in Crack Detection

For instance, ultraviolet light, particularly UV-A light, helps to expose cracks located on the surface. It combines with fluorescent penetrants such as dye, making them fluoresce, thus showing the presence of cracks where such penetrants have seeped in. The naked eye can see even very small cracks due to this fluorescence.

Fluorescent Penetrant Inspection (FPI) Process

Preparation of Surface: The entire content is then thoroughly cleaned to eradicate any foreign object debris that would hinder proper examination.

Application of Penetrant: A fluorescent penetrant is applied to the surface. This type of penetrant has the ability to penetrate cracks that are on or near the surface.

Dwell Time: The penetrant is left for a given period to reach the bottom of any defects found on the surface.

Excess Penetrant Removal: After its dwell time, excess penetrant is wiped off, leaving only that entrapped within the defect openings.

Application of Developer: The process begins by applying a developer onto the surface. This pulls out any remaining penetrants from within these cracks, causing them to be more visible.

Inspection under UV Light: To examine the part’s surface for possible cracks, which will appear bright when examined under UV-A light

Evaluation: The indications are assessed for qualifying and quantifying the nature and extent of crack damage (Johnston).

Why It’s Unique?

The UV100-N 365nm LED flashlight is not just another inspection tool—it’s a precision-engineered solution designed for serious professionals in the non-destructive testing (NDT) industry. What sets it apart is a thoughtful combination of performance, durability, and convenience.

Sensitivity

Micro cracks, hairline fractures, and surface flaws that may go unnoticed by other inspection methods can be revealed through UV inspection, primarily using fluorescent penetrant inspection (FPI). The response that is glowing from fluorescent dyes under 365nm UV light will increase defects visibility even on complex surfaces.

Fast Inspections

A high output intensity of 15,000 μW/cm² allows for a wider field of view and faster scanning when inspecting large areas or several smaller ones. For example, the UV-A headlamp with a beam diameter of up to 100mm makes it possible to scan a larger area without increasing the time spent inspecting the surface.

High Intensity

The UV crack detection method is more affordable compared to other NDT techniques like ultrasonic or radiographic testing. The equipment, such as the UV100-N UV flashlight, is not only pocket-friendly but also durable and provides good performance for a long period of time.

Applications Across Industries

Aerospace

In the aerospace industry, component integrity is paramount. FPI using UV light allows detecting even microscopic cracks in engine parts, fuselage, and other vital components, hence saving potential failures.

Automotive

UV-based crack detection is used in automobile assembling firms to inspect engine blocks, chassis, among other components that ensure the safety and reliability of vehicles on the road.

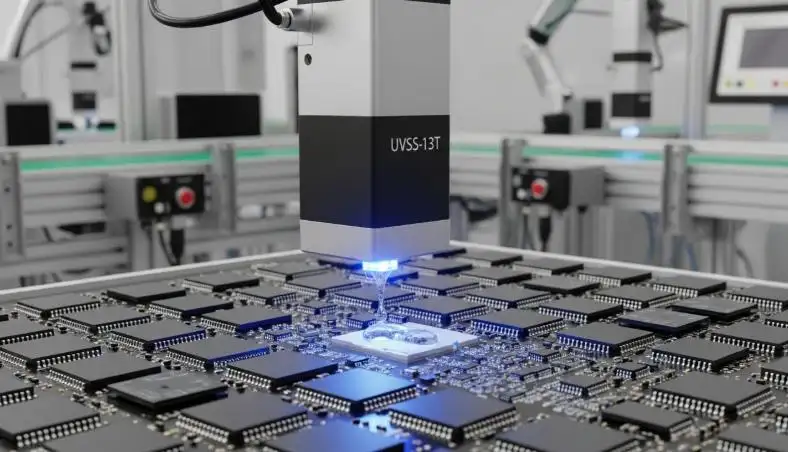

Manufacturing

While manufacturing, especially casting and forging processes, early identification of surface defects through UV inspection reduces the chances of defective products entering the market.

You can use a UV light to check for surface cracks in concrete and structural inspections, which may compromise the integrity of buildings and infrastructure.

Acquiring the Appropriate UV Equipment for Surface Crack Detection

Accuracy, safety, and efficiency are highly dependent on the correct selection of equipment when it comes to detecting surface cracks using UV radiation. The quality and specifications of your UV lamps directly contribute to the success of your operations, whether you are performing fluorescent penetrant inspection (FPI) or magnetic particle inspection (MPI).

Key Factors to Consider

UV-A Intensity

Cracks and defects must be clearly shown through high-intensity ultraviolet-A lights. Premium models like the UV100-N have units delivering up to 15,000 μW/cm², while others should deliver at least 5,000 μW/cm².

Portability

If you are inspecting on-site, then portability is necessary. Cordless compact UV lamps give inspectors greater freedom of movement regardless of whether they operate around complex equipment, tight spaces, or remote areas.

Wavelength Accuracy

For NDT and FPI applications, your ultra-violet light should simply work within the range of 320-400 nm, although within the industry standard, it is 365 nm.

Battery Life

The amount of downtime experienced is reduced by long-lasting battery life. Choose lights that have batteries that last between four and six continuous hours, especially during field work.

Industrial Durability

The equipment must be manufactured from anodized aluminum or other non-corrosive materials. It should also be able to withstand dust, oil, and high temperatures.

Safety Considerations

Although it is not invasive, UV inspection needs a great deal of care:

• Protective Eyewear: Always wear UV-blocking safety glasses to prevent eye damage.

• Skin Protection: Limit direct skin exposure and wear long sleeves or gloves during extended use.

• Training: Ensure all personnel are properly trained in UV inspection techniques and understand UV safety protocols.

Conclusion

Surface crack detection UV is vital for ensuring the integrity of materials used in various industries. The technique employs principles of Fluorescent Penetrant Inspection (FPI), which enables identification and prompt correction of even the slightest surface imperfections. With appropriate equipment and safety precautions in place, this sort of crack detection using ultraviolet rays provides an affordable and practical means for sustaining structural soundness.