What then are Tailored Curing Systems?

Tailored curing systems represent highly customized technologies that are expected to fit the nature of curing requirements of the different industries. At this point, the systems encourage flexibility, accuracy, and automation, and hence are best suited to present-day manufacturing as compared to conventional curing tools.

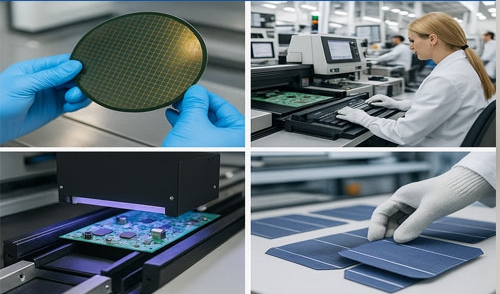

Fields where tailor-made curing systems can help out are as follows:

•Printing industries- achieving clear and bright results.

•Coatings and adhesives-polymerization and adhesion that is consistent.

•Production of electronics- enables perfect curing of the weak components.

•Automotive and aerospace- they enhance long-lasting coating of high performance.

Integration and Automation reception

Tailored curing systems can be custom-made to fit perfectly on the current line of production. The feature of automation and its ability to control and modify the process in real-time allows the process to be cured consistently, eliminating the possibility of human error and increasing the percentage of reliability even further.

UV Tape Curing Systems Agtie Features & Uses

- UV Tape Curing Wafer Processing

UV tape curing is a necessary step in the process of wafer dicing and back grinding, too. The tape is exposed to UV-light and picked and handled easily with fewer handling errors. This is so that the protection of the sensitive semiconductor wafers can be done while also time high accuracy in manufacturing also maintained. As tape bonding decreases, the firms can achieve separation of the chip that is more efficient and less rugged.

- Bespoke of Resources

The tapes that are subjected to UV dicing may be applied to a wide range of materials. They can also be applied to glass, ceramics, etc., in addition to semiconductor wafers. This kind of flexibility makes the UV tape curing very much applicable in different industries, up to the electronics industry, precision glass components, and many more, and it gives the manufacturers a lot of freedom and certainty in fulfilling demanding production requirements.

- Increased Process Productivity

The UV tape curing machines enhance the efficiency in the production. The speed of response is faster, suprachronic recovery rates are improved, and hold time is reduced system-wide, thus achieving increased productivity. The enhanced productivity helps manufacturers avoid the expenses of delays, complex processes, and fluctuations of performance along the production lines that require deliveries within a shorter deadline without affecting the quality.

Notable advantages of UV Tape Curing

- Productivity Improvement

UV LEDs are very efficient and fast because they bypass the slowing down of the processes due to adhesion of the tape, since cold-streaming facilities are employed. This directly boosts the throughput and decreases downtimes, which helps the manufacturers to have an increase in the number of operations performed.

- Time efficient & environment friendly

They are deemed as less hazardous both to the personnel and the environment because the UV tape setting up mechanisms do not generate ozone or mercury. Being capable of minimizing regulatory issues along with aiding in environmentally friendly modes of production, this design has proved to be overly beneficial.

- Easy to apply & General versatility

In touchscreen interfaces, preset parameters make the procedure easily controllable so that the operators can avoid challenges in the handling of the different steps involved. Additionally, the tapes and wafers may be developed in various sizes to meet a given production need, and the solution is, therefore, very customized and versatile.

- Production Line- Curing Machines

Automated LED curers with production lines ensure consistency of the process. Consistency of quality and speed is enabled by built-in sensors and controls.

Technical Insights: Functioning of Targeted Curing Systems

Advanced curing systems have integrated the usage of UV light sources, advanced machinery, and smart software to offer optimal curing. Certain wavelengths created by UV LED curing devices are used to trigger the polymerization of the coatings and adhesives, or inks. The notable technical fact is:

- Wavelength Selection: Various materials should be cured with different wavelengths. The systems utilized today reside in a part of the 365- 405 nm range, thus adaptable to several materials.

- Control of Intensity: The power can be controlled, which can allow curing without damage to the materials in a short period.

- Exposure Time: High throughput and the balance of exposure is offered at short and accurate exposure.

- Temperature Management: LEDs generate minimal heat, similar to traditional lamps, hence eliminating their destruction through heat.

The Repository of the Appropriate, Customized Curing System

Care should also be taken in choosing an optimized curing system that will effectively reduce the production cost of the business and produce quality work. The decision must be formulated with the assistance of some key factors, which are supposed to be aligned with the requirements of the industry.

1. Industry Requirements

The curings that are needed are varied among industries. Both printing and coatings, and adhesives require the ideal amount of cure intensity, wavelength, and exposure time. The system that can be selected in particular by the industry will result in more stable outcomes and waste of fewer material.

2. Production Volume

The other significant thing is the level of production. Since the use of high-speed systems is on a large scale and tailored high-speed curing systems are in place, the throughput can be boosted without compromising the level of quality. To some extent, smaller operations can take advantage of flexible and modular systems that are easily changed using other batch sizes.

3. Material Compatibility

Not all materials act in the same manner to UV curing. Polymer, coatings, and glue cure may require that UV wavelengths be used that only fit. An adjustable wavelength and intensity system can render it compatible with every material.

4. Energy Efficiency

Energy-efficient systems are cost-saving in both the nature of operations as well as environmental impacts. The UV LED lighting mechanisms consume less energy as compared to the conventional mercury lamps and produce faster and reproducible results.

5. Automation Level

The systems that demand less labor, include fewer incidences of human error, are more exacting are known to be highly automated. The devices are efficient and reliable because they have touchscreen displays, adjustable parameters, and real-time oversights.

With the above factors in consideration, manufacturers can choose an option of a custom curing system that provides them with certain features such as high productivity, uniformity in quality, and facilitating viable operations.

Conclusion

The manufacturing of the future industries is customized healing. Manufacturers might become highly efficient, very reliable, and flexible with an in-built custom Tailored Curing Systems, automated LED curing system, and machinery of high-quality precision control. Cooperation with a partner such as UVET will ensure a unique approach to addressing the problem of curing and maximum adherence to the requirements of your production. Production lines rely on innovation, productivity, and sustainability, which are exclusively attainable through an investment in an individual curing solution.